Biomask and method for patterning on substrate

A mask and patterning technology, which is applied in the photoengraving process of the pattern surface, the originals and instruments for photomechanical processing, etc., can solve the problem of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

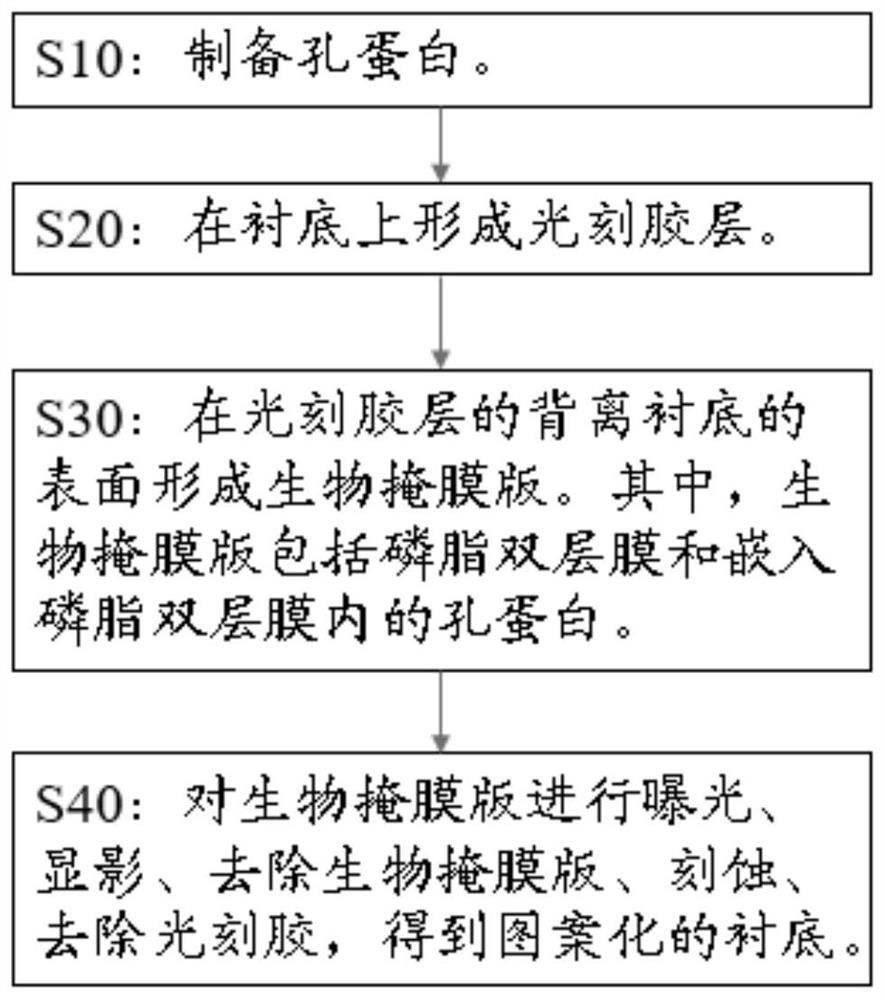

Method used

Image

Examples

Embodiment 1

[0082] This embodiment provides a method for preparing a monolithic interlayer through hole, including the following steps:

[0083] (1) Select a silicon wafer with a crystal phase of and a thickness of 50 μm, with a dense silicon dioxide layer of 10 nm thick on the surface, and clean the silicon wafer according to the RCA standard process flow.

[0084] According to the coating speed of 3000rpm, the coating acceleration of 2000rpm / s, and the coating time of 20s, the above-mentioned cleaned silicon wafers were coated with a positive photoresist. After the coating is completed, it is dried at a temperature of 100°C for 180s.

[0085] (2), immerse the silicon wafer with the photoresist layer in the NHS / EDC mixture (2.0mmol / LNHS+1.0mmol / L EDC) to activate for 10min, then immerse it in the 0.1mol / L avidin solution for protein Fixed for 5 minutes. Spin-coat 1ml of DPPC vesicle solution on the surface of the silicon wafer after protein immobilization at a spin-coating speed of 20...

Embodiment 2

[0090] The difference between Example 2 and Example 1 is that the porin is PlyAB.

[0091] In this embodiment, the line width of the through hole on the silicon chip can be as low as 14nm.

Embodiment 3

[0093] The difference between Example 3 and Example 1 is that the vesicle solution is clathrin-coated vesicle solution.

[0094] In this embodiment, the line width of the through hole on the silicon chip can be as low as 7nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com