On-line detection device for non-contact measuring hole and use method thereof

A detection device and non-contact technology, applied in the field of inspection and detection, can solve the problems of photo quality reduction due to lighting conditions, weak skin rigidity and repeated clamping, unfavorable rapid detection of a large number of holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

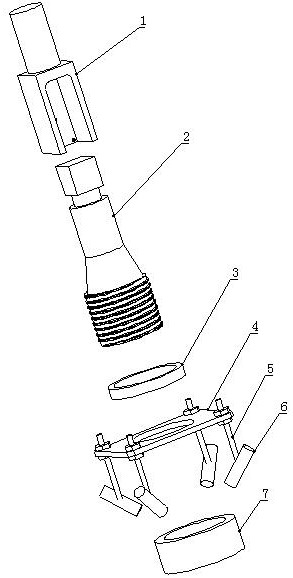

[0073] refer to figure 1 , an online detection device for non-contact measuring holes, including a fixture 1, a camera 2, a snap ring 3, a bracket 4, a coupling rod 5, a laser generator 6, and an illumination compensator 7.

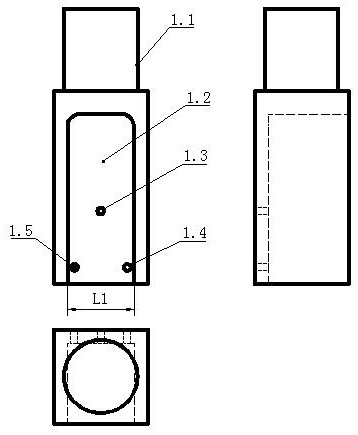

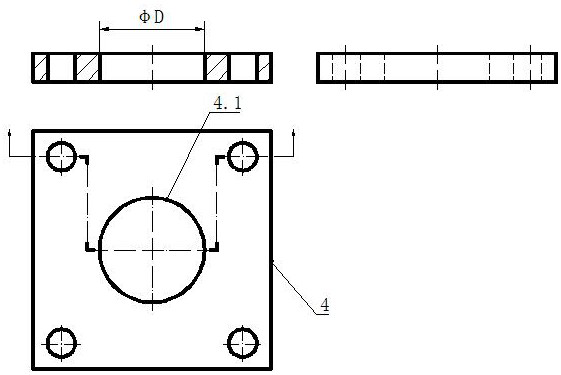

[0074] refer to figure 2 and Figure 4 , the clamp handle 1.1 is a cylindrical structure, the width of the clamp groove 1.2 The width of the upper end of the camera 2.1 The camera upper end 2.1 fits into the fixture groove 1.2 and forms an interference fit. The sides of the fixture groove 1.2 are shaped with apertures of The first light hole 1.3, the second light hole 1.4, and the third light hole 1.5, and the side of the upper end 2.1 of the camera is provided with the first threaded hole 2.2, the second threaded hole 2.3, and the third threaded hole whose thread specifications are all M3 2.4. Camera 2 is equipped with a telecentric lens. refer to Figure 7 , the first screw 8, the second screw 9, and the third screw 10 of which the three thr...

Embodiment 2

[0078] Based on the online detection device for non-contact measuring holes described in Embodiment 1, this embodiment provides an online detection method for non-contact measuring holes, refer to Figure 9 , in order to realize the measurement of the hole, the following steps are included:

[0079] Step 1: Install the jig handle 1.1 of the online detection device on the tool handle 11, and connect the tool handle 11 to the spindle of the machine tool to ensure that the camera 2, the jig handle 1.1, and the spindle of the machine tool are coaxial.

[0080] Step 2: Place the sample 12 with standard holes on the workbench, move the spindle of the machine tool to the top of the hole in the sample 12, that is, the axis of the spindle coincides with the axis of the hole, and move from the light compensator 7 to the upper surface of the sample 12 The strong light is emitted to obtain the compensation light source required by the camera 2 to take pictures, and the laser is emitted fr...

Embodiment 3

[0112] In order to realize the measurement of the hole, the present embodiment provides a kind of online detection method for the non-contact measurement hole. On the basis of Example 2, the method is described with more specific numerical values. The steps are as follows:

[0113] Step 1: Refer to Figure 6 , the fixture handle 1.1 of the online detection device is installed on the tool handle 11, and the tool handle 11 is connected with the machine tool spindle to ensure that the camera 2, the fixture handle 1.1, and the machine tool spindle are coaxial.

[0114] Step 2: Refer to Figure 6 , place the sample 12 with an aperture of φ6 on the workbench, make the center of the hole at X=0, Y=0, and the upper surface of the hole at Z=0. The spindle of the machine tool moves to directly above the hole in the sample 12, that is, the spindle coordinates X=0 and Y=0, emits strong light from the light compensator 7 to the upper surface of the sample 12 so as to obtain the compensati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com