High-stability chemical storage tank

A technology for chemicals and storage tanks, which is applied in the direction of tank cars, layered products, containers, etc., and can solve problems such as being easily affected by environmental factors, poor performance, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

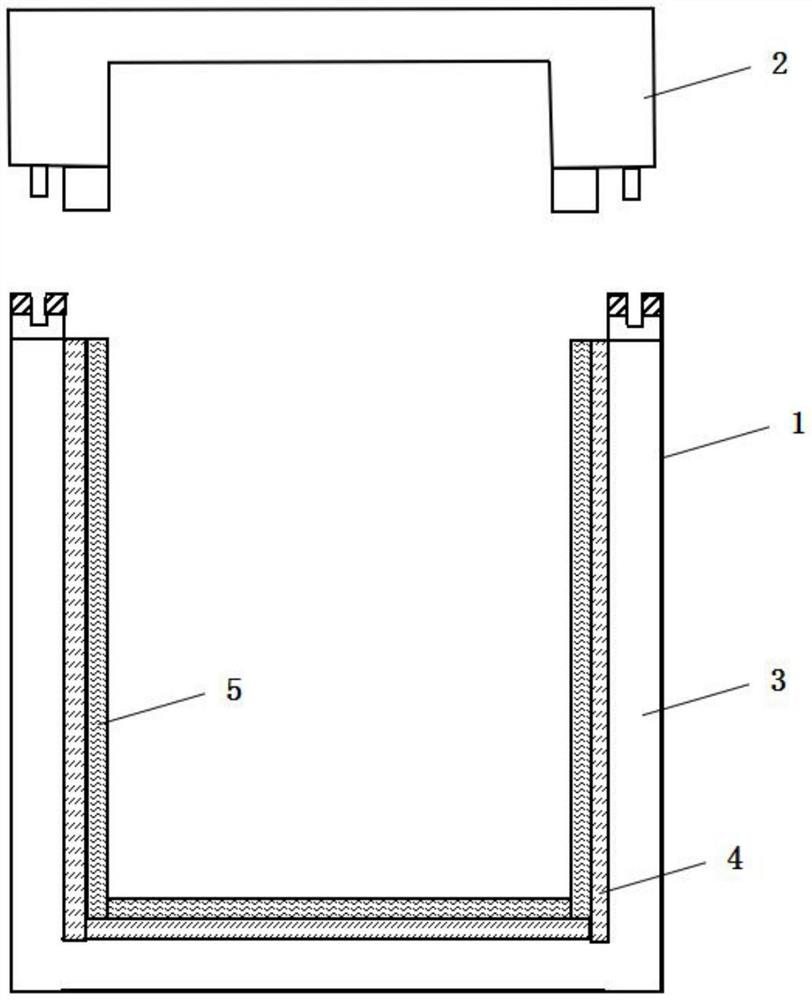

[0039] A chemical storage tank with high stability, comprising a tank body and a cover body, the tank body includes a glass shell layer, the inside of the glass shell layer is coated with a temperature-regulating and humidity-regulating coating, and the glass shell layer The inner wall is sequentially provided with an insulation layer, a moisture-proof layer and a hollowed-out board layer from the outside to the inside. The temperature-regulating and humidity-regulating coating is coated on the hollowed-out board layer. Functional filler;

[0040] The preparation method of the temperature-regulating and humidity-regulating coating is as follows, in parts by weight, weighing 25 parts of water-based acrylic resin, 18 parts of temperature-regulating functional fillers, 20 parts of humidity-regulating functional fillers, 1.5 parts of DH4450, 1.2 parts of KH570 , 23 parts of water, mixed evenly, coated and dried;

[0041] The temperature-regulating functional filler is a phase-chang...

Embodiment 2

[0055] A chemical storage tank with high stability, comprising a tank body and a cover body, the tank body includes a glass shell layer, the inside of the glass shell layer is coated with a temperature-regulating and humidity-regulating coating, and the glass shell layer The inner wall is sequentially provided with an insulation layer, a moisture-proof layer and a hollowed-out board layer from the outside to the inside. The temperature-regulating and humidity-regulating coating is coated on the hollowed-out board layer. Functional filler;

[0056] The preparation method of the temperature-regulating and humidity-regulating coating is as follows, in parts by weight, weighing 25 parts of water-based acrylic resin, 18 parts of temperature-regulating functional fillers, 20 parts of humidity-regulating functional fillers, 1.5 parts of DH4450, 1.2 parts of KH570 , 23 parts of water, mixed evenly, coated and dried;

[0057] The temperature-regulating functional filler is a phase-cha...

Embodiment 3

[0072] On the basis of Example 1, the preparation method of the temperature-regulating functional filler is:

[0073] Step 1. Pre-processing

[0074] Weigh the nanocellulose and disperse it in 5mol / L cold hydrochloric acid solution. Under the condition of stirring, gradually raise the temperature of the mixture to 90-100°C and heat it to reflux for 2-3 hours. After cooling, separate the precipitate and wash it with distilled water until Neutral, vacuum dried at 60°C for 24 hours; wherein, the liquid-to-solid ratio of the nanocellulose to the hydrochloric acid solution is 40-50ml / g;

[0075] Step 2, modification treatment

[0076]Weigh the nanocellulose obtained in step 1 and stir and disperse it in an equal volume of mixed methanol-pyridine mixed solvent. After the dispersion is uniform, the temperature of the mixture is gradually raised to 35-45°C. Under stirring conditions, add acryloyl chloride drop by drop After the dropwise addition, continue to stir and react for 0.5-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com