Method for preparing tetrahydrofuran dimethanoldialkyl ether

A technology of tetrahydrofuran dimethanol dialkyl ether and tetrahydrofuran dimethanol, which is applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

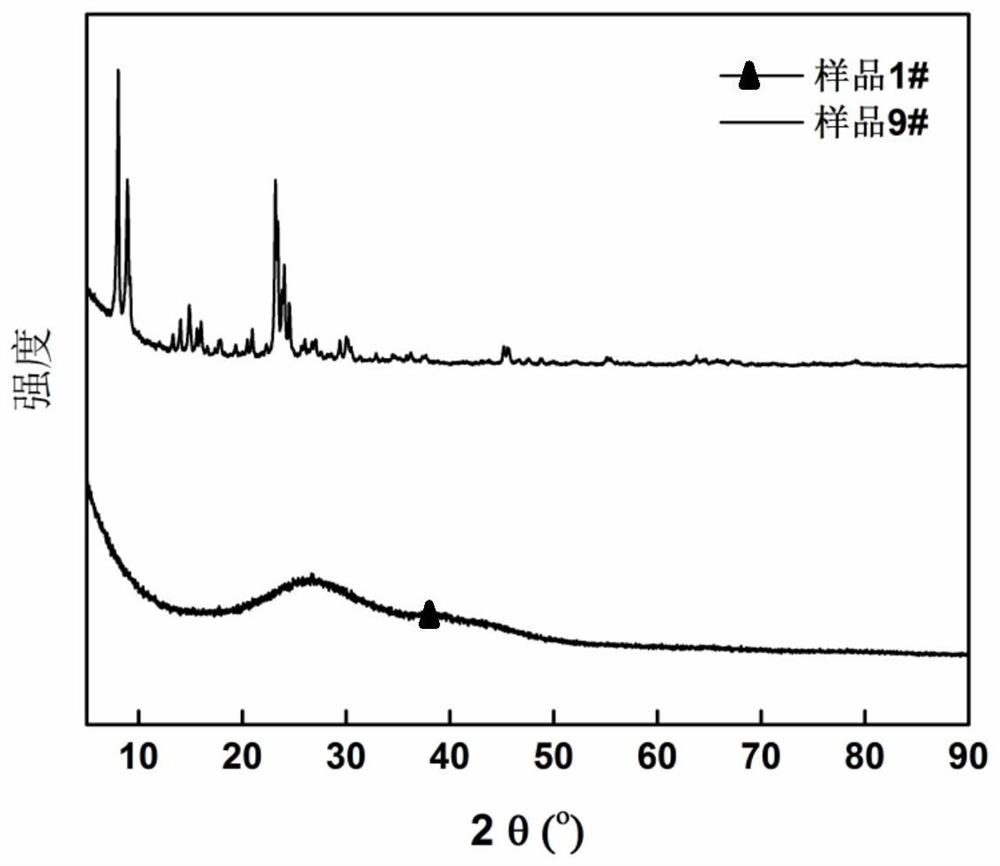

[0040] Example 1 Sample 1 # preparation

[0041] Add 0.5g of palladium nitrate to 20ml of deionized aqueous solution, stir until completely dissolved, weigh 10g of granular activated carbon and add it to the above solution, soak it at room temperature for 48h, dry it in an oven at 80°C for 2h, and then transfer to In the muffle furnace, after calcination at 500°C for 7h, the Pd / C catalyst was obtained, which was designated as sample 1 # . (the mass content of the active ingredient is 2%)

Embodiment 2

[0042] Example 2 Sample 2 # preparation

[0043] Add 0.5g of chloroplatinic acid to 20ml of deionized water solution, stir until completely dissolved, weigh 10g of granular activated carbon and add it to the above solution, soak it at room temperature for 48h, dry it in an oven at 80°C for 2h, and then transfer In the muffle furnace, after calcination at 500°C for 7 hours, the Pt / C catalyst was obtained, which was designated as sample 2# . (the mass content of the active ingredient is 2%)

Embodiment 3

[0044] Example 3 Sample 3 # preparation

[0045] Add 0.5g of palladium nitrate to 20ml of deionized aqueous solution, stir until completely dissolved, weigh 10g of granular alumina and add it to the above solution, soak it at room temperature for 48h, dry it in an oven at 80°C for 2h, and then transfer to In a muffle furnace, after calcination at 500°C for 7h, Pd / Al 2 o 3 Catalyst, denoted as sample 3 # . (the mass content of the active ingredient is 2%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com