Control method of steam system

A control method and technology of a steam system, which is applied in the field of steam heating and cooking, and can solve problems such as unfavorable steam system energy saving and emission reduction, inability to control steam generator steam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

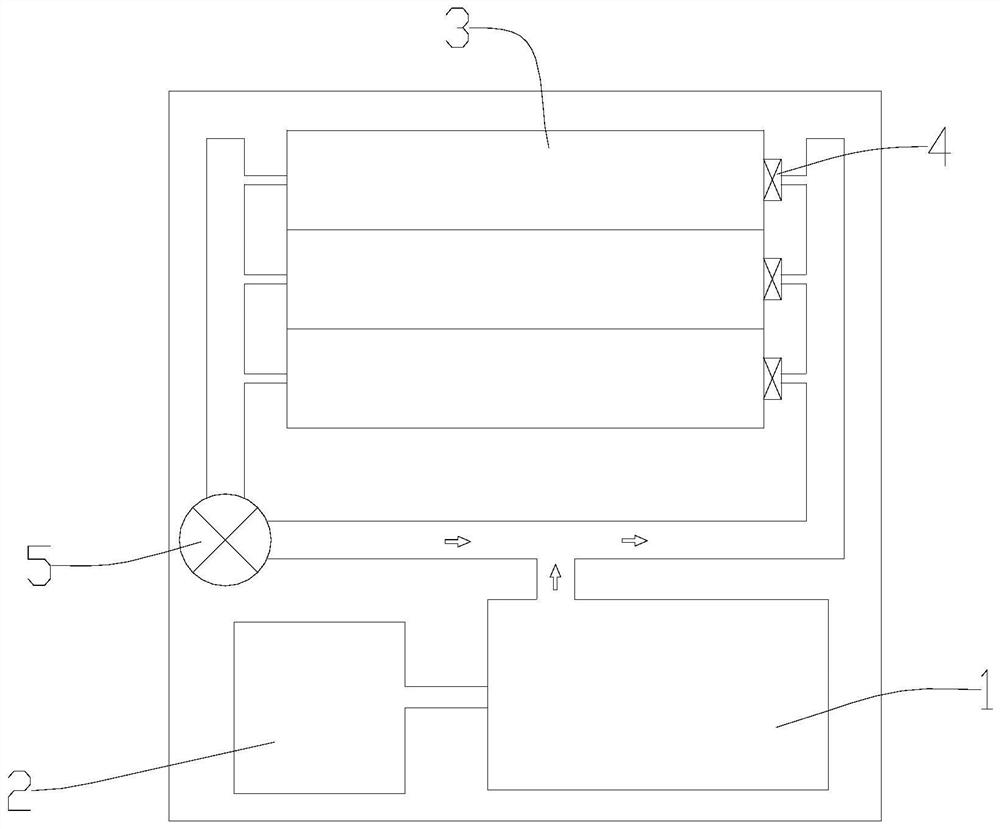

[0026] A method for controlling a steam system, comprising a steam generator 1, a steam cabinet, a fan and a proportional valve; providing premixed gas 2 to the steam generator 1 through the fan and the proportional valve, forming a steam circuit in the steam cabinet, The steam generator 1 generates steam and delivers the steam to the steam circuit. There are a plurality of unit cabinets 3 in the steam cabinet, and each unit cabinet 3 is provided with a temperature sensor. The steam circuit A steam branch is respectively formed to communicate with each unit cabinet 3, and the unit cabinet 3 is provided with a steam valve 4 at the steam inlet connected to the steam branch, and the steam valve 4 is used to open or close the unit cabinet The corresponding steam branch of body 3; Described control method comprises the following steps:

[0027] Controlling the speed change of the fan to form a plurality of wind speed gears, there are high-speed gears and low-speed gears in the gear...

Embodiment 2

[0034] Such as figure 1 As shown, a more preferred implementation is provided on the basis of Example 1. The steam cabinet is provided with three unit cabinets 3, and the temperature sensor and steam valve 4 are arranged in accordance with the number of unit cabinets 3, so Described control method comprises the following steps:

[0035] Controlling the rotation speed of the fan to form at least six wind speed gears, the wind speed of the gears from low to high includes the first low speed gear, the second low speed gear, the third low speed gear, the first high speed gear, and the second high speed gear. gear and the third high-speed gear;

[0036] Detect the state of the steam valve 4 to determine the number of unit cabinets 3 in operation;

[0037]When the number of unit cabinets 3 in operation is 1, match the first low-speed gear and the first high-speed gear; if the measured temperature is less than or equal to the set lower limit temperature, switch the gear of the fan ...

Embodiment 3

[0041] On the basis of Embodiment 1 and Embodiment 2, the energy-saving effect of the steam system is further improved.

[0042] Described steam generator 1 comprises water tank, and described water tank is provided with blowdown valve and water level sensor, and described water level sensor is used for sensing the water level in described water tank, and described control method comprises the following steps:

[0043] Open the sewage valve to discharge sewage. When the water level sensor senses that the water level signal in the water tank is lower than the set low water level signal, and maintains the state of being lower than the set low water level signal for the first set time, it is judged that the sewage is completed. . Sewage with impurities such as solid residues will remain in the water tank of the general steam generator 1. If the sewage is not removed in time, it will greatly affect the heat exchange efficiency and life of the steam generator 1, and the existing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com