Power station boiler fan efficiency real-time online calculation method based on DCS parameters

A power plant boiler and calculation method technology, applied in calculation, data processing applications, instruments, etc., can solve the problems of uneven distribution of flow field, difficulty in ensuring measurement accuracy, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

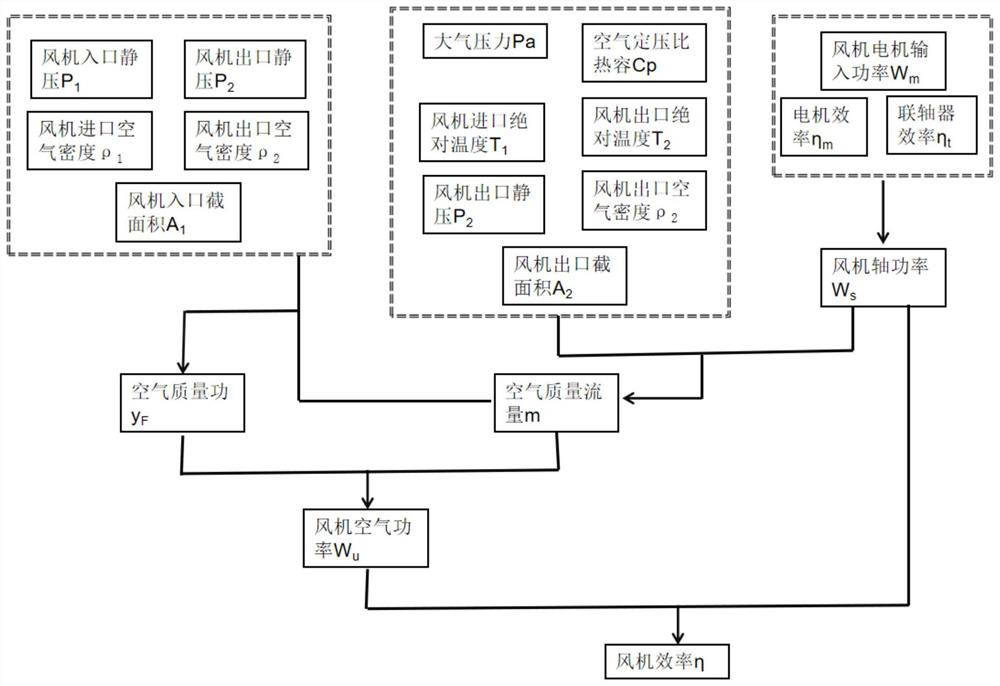

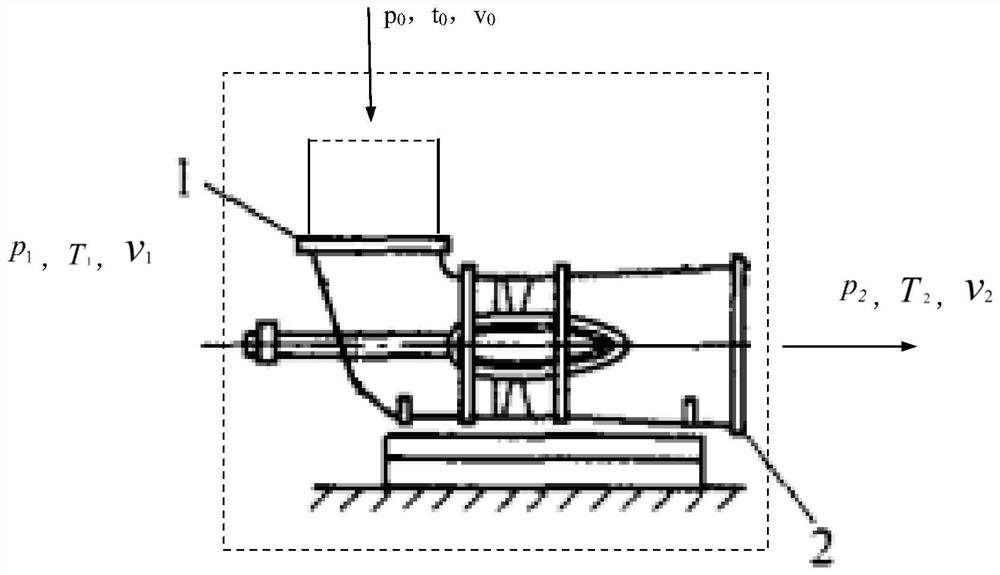

[0051] The system as a blower opening system, such as fan system schematic diagram figure 2 Indicated. like figure 1 Shown, the real time power plant boiler fan efficiency calculation method based DCS parameter, comprising the steps of:

[0052] Step 1, the fan axis of the fan shaft system obtained from the motor supporting mechanical power W s Effect of inhalation air from the atmosphere, the air enters the blower through the body after a short fan inlet duct, after the fan impeller driven, air leakage and the like is ignored, the air velocity v 2 Delivered to the fan outlet duct; real-time recording of atmospheric ambient air pressure p a Record the fan motor input power W m , Fan inlet static pressure p 1 , Fan inlet air absolute temperature T 1 , P static pressure fan outlet 2 Fan outlet air absolute temperature T 2 ; Fan inlet cross-sectional area was measured to be A 1 ; Fan outlet area measured as A 2 ; Process air intake fan, the recording surface of the heat loss from the...

Embodiment 2

[0088]Taking 1 a fan in a power plant as an example, the fan efficiency is calculated using the method in Example 1, and the performance test results of the fan performance test, the calculation and alignment results are shown in Table 1, from the comparison result, The relative deviation calculated by the above method is less than ± 5%, and the accuracy is high.

[0089] Table 1 Fan performance test calculation and comparison results

[0090] parameter name symbol unit Working condition 1 Working condition 2 Working condition 3 Working condition 4 Atmospheric pressure p a

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com