Separated lens antenna and communication equipment

A lens antenna, in vitro technology, applied to antennas, antenna arrays, antenna arrays that are individually powered, etc., can solve the problems of narrow beam width and lack of one-dimensional continuous beam scanning capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

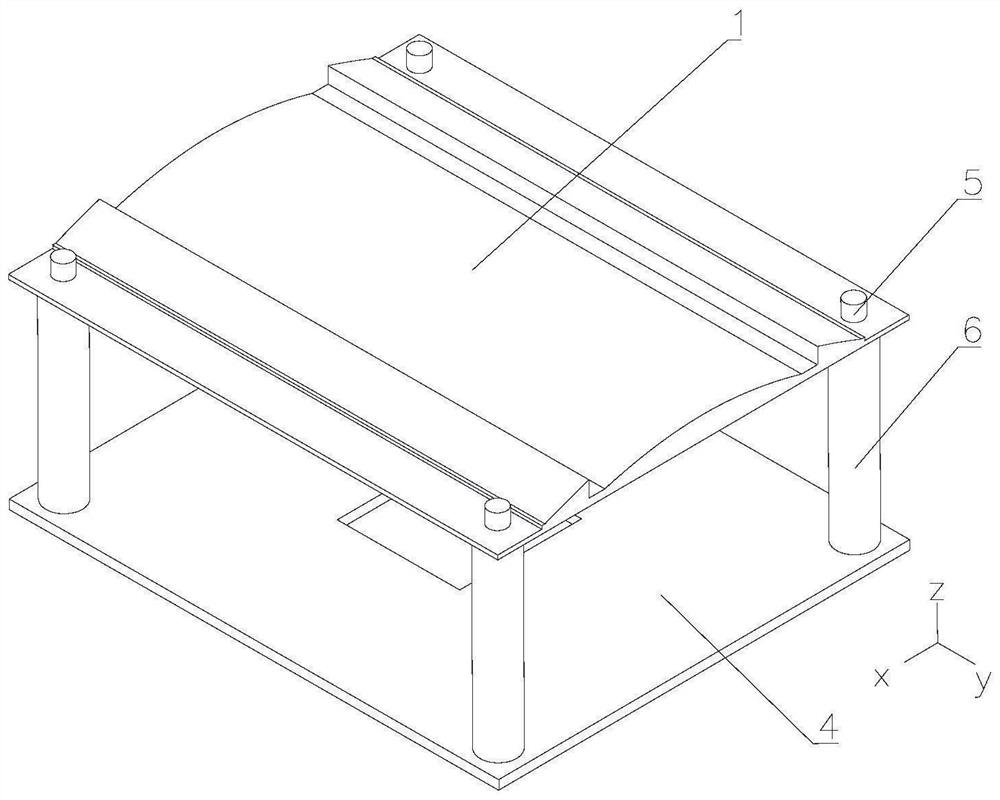

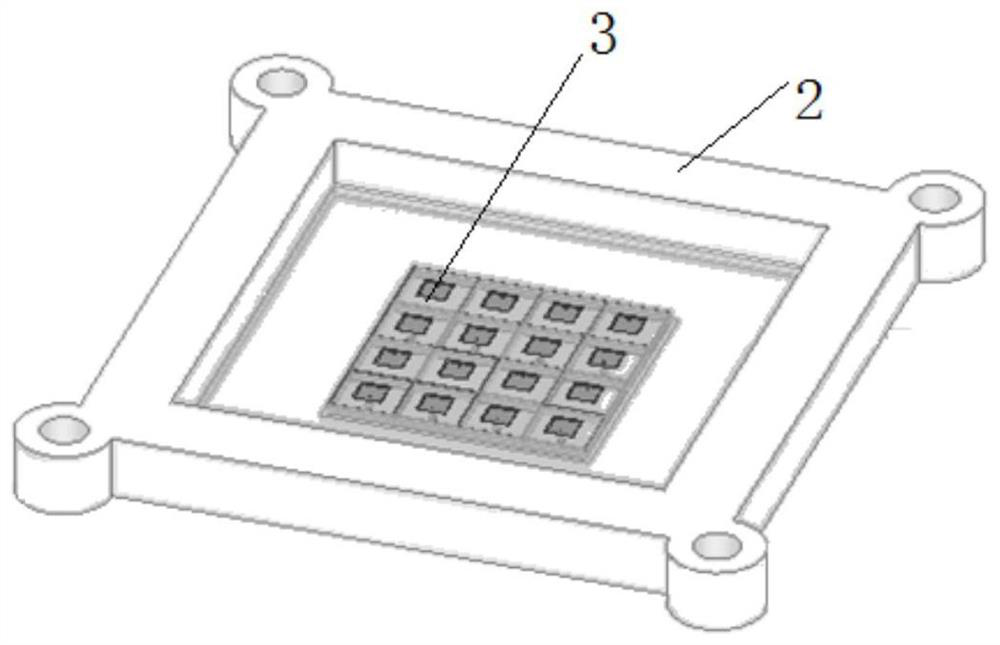

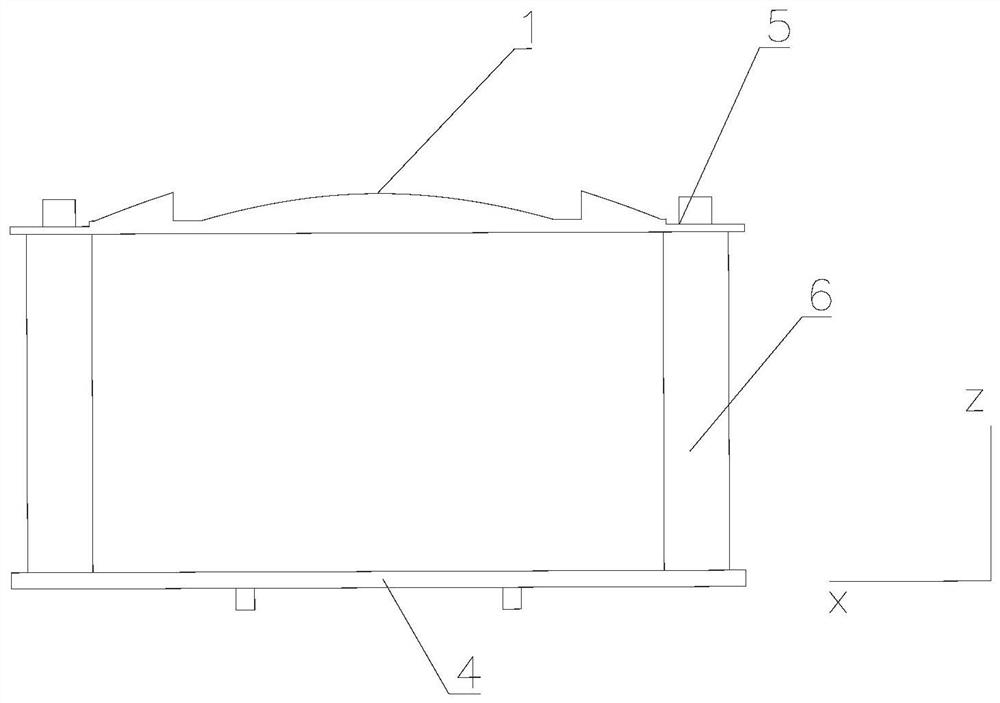

[0055] Please refer to figure 1 and figure 2 , an isolated lens antenna, comprising a dielectric lens 1, a base 2, a microstrip radiation unit 3 and a lens holder 4; the dielectric lens 1 is arranged on one side of the lens holder 4; one side of the dielectric lens 1 It is a plane, and the other side is a convex surface whose height varies along a single dimension; the other side of the lens holder 4 is connected to the base 2; the microstrip radiation unit 3 is arranged on one side of the base 2, and Located in the base 2; the distance from the dielectric lens 1 to the microstrip radiation unit 3 is equal to the focal length of the dielectric lens 1; the base 2 is provided with a groove near the side of the lens holder 4; the The microstrip radiation unit 3 is arranged in the groove;

[0056] Please refer to Figure 1 to Figure 4 , the dielectric lens 1 in this embodiment is composed of an integrated medium, one side of the integrated medium is a plane, and the other side...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that this embodiment limits the composition of the lens;

[0061] Please refer to Figure 5 , the dielectric lens 1 includes a plurality of dielectric pillars 7 with different heights; one side of the plurality of dielectric pillars 7 is spliced to form the plane; the other side of the plurality of dielectric pillars 7 is in a preset first dimension There is a height change in the direction, and the convex surface with uneven height is formed by the height change in a single dimension direction;

[0062] Specifically, please refer to Image 6 , the medium column 7 is a cylinder; the sides of the adjacent cylinder medium columns 7 are tangent; one side of the plurality of cylinders is on the same plane, and the other side of the plurality of cylinders forms The height change in the single-dimensional direction; the cylindrical dielectric column 7 has different height changes along the x-axis direction, wherei...

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 or 2 is that the direction of the lens convex surface is limited;

[0066] In an alternative implementation, please refer to figure 1 and Figure 5 , the plane of the dielectric lens 1 is set towards the base 2; as in Embodiment 1 and Implementation 2, the convex surface of the lens antenna is set on the side away from the base 2;

[0067] In another alternative implementation, please refer to Figure 7 and Figure 8 , the convex surface of the dielectric lens 1 is set towards the base 2; specifically, take the cylindrical dielectric column 7 in Embodiment 2 as an example; the cylindrical dielectric column 7 has different height changes along the x-axis direction At the same time, the direction of its height change is toward the negative semi-axis direction of the z-axis, that is, extending toward the base 2; and the height direction of the cylindrical dielectric column 7 is changed along the negative semi-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com