Outlet collector of vacuum oil filter

A vacuum oil filter and collector technology, which is applied to containers, motor vehicles, large containers, etc., can solve the problem of further limiting the storage of clean oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

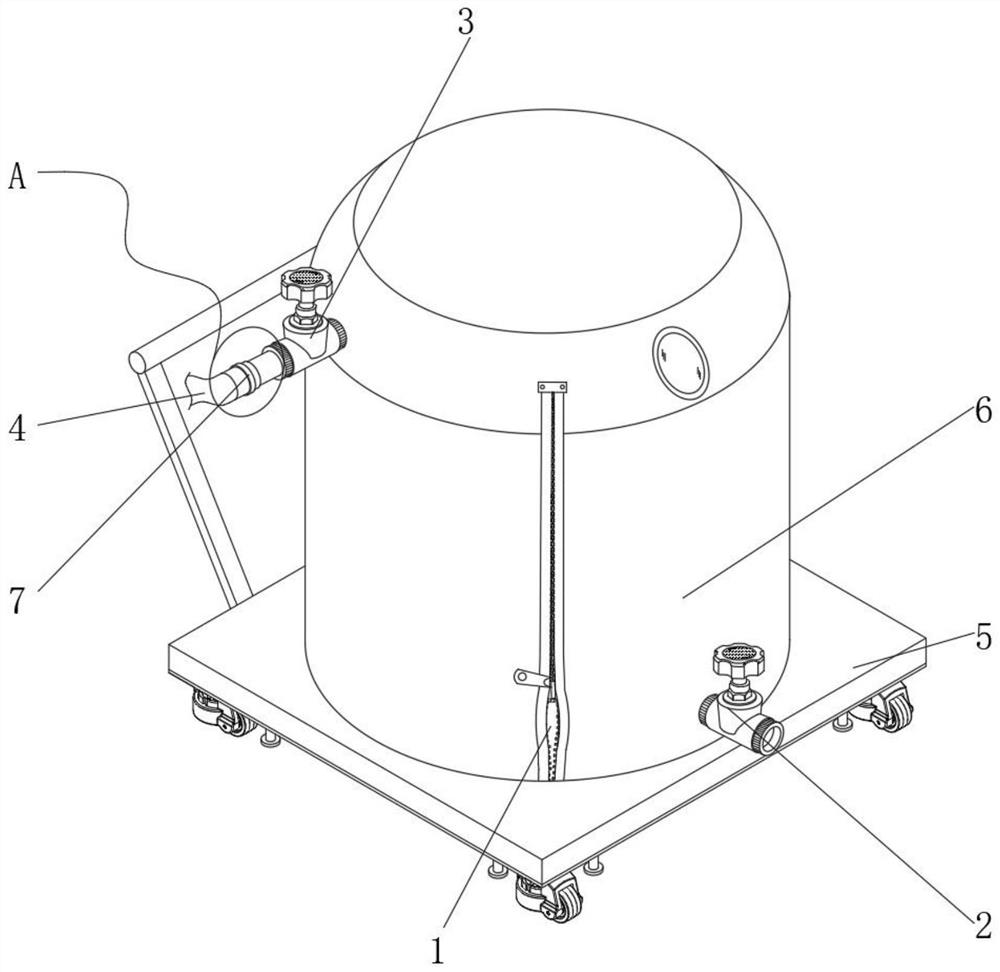

[0028] This embodiment is an outlet collector of a vacuum oil filter.

[0029] like Figure 1-5 As shown, an outlet collector of a vacuum oil filter includes an oil storage tank 1, the lower section of the oil storage tank 1 is provided with an oil outlet valve 2, and the upper section of the oil storage tank 1 is provided with an oil inlet valve 3, and the oil inlet valve One end of 3 is provided with an oil discharge pipe 4, the overall outer wall of the oil storage tank 1 is sleeved with a heat preservation mechanism 6, and the outer surface of the lower end of the oil storage tank 1 is provided with a handling mechanism 5, and between the oil inlet valve 3 and the oil discharge pipe 4 is provided with a heat preservation mechanism 6. Connection mechanism 7.

[0030] The oil storage tank 1 is integrated with the oil outlet valve 2 and the oil inlet valve 3. One end of the oil inlet valve 3 is detachably connected to the oil discharge pipe 4 through the connecting mechanism...

specific Embodiment 2

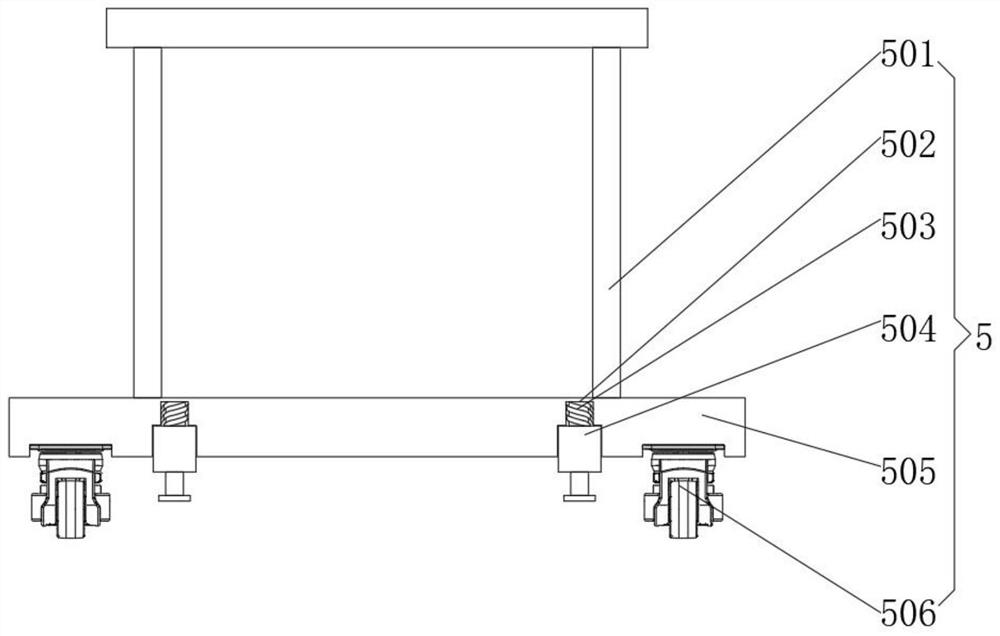

[0033] This embodiment is an embodiment of a conveying mechanism for an outlet collector of a vacuum oil filter.

[0034] like figure 1 , 2 As shown, a handling mechanism for the outlet collector of a vacuum oil purifier, the handling mechanism 5 includes a push handle 501, an installation groove 502, an installation stud 503, a cylinder 504, a fixed base 505, a universal wheel 506, and the fixed base 505. The outer surface of the upper end is fixedly connected with the outer surface of the lower end of the oil storage tank 1, the push handle 501 is located on the outer surface of the rear end of the fixed base 505 and is welded to it, and the four universal wheels 506 are based on the central rectangular array of the outer surface of the lower end of the fixed base 505 and All of them are fixedly connected to it, and the four installation slots 502 are all opened on the outer surface of the lower end of the fixed base 505 and are based on the central rectangular array of the...

specific Embodiment 3

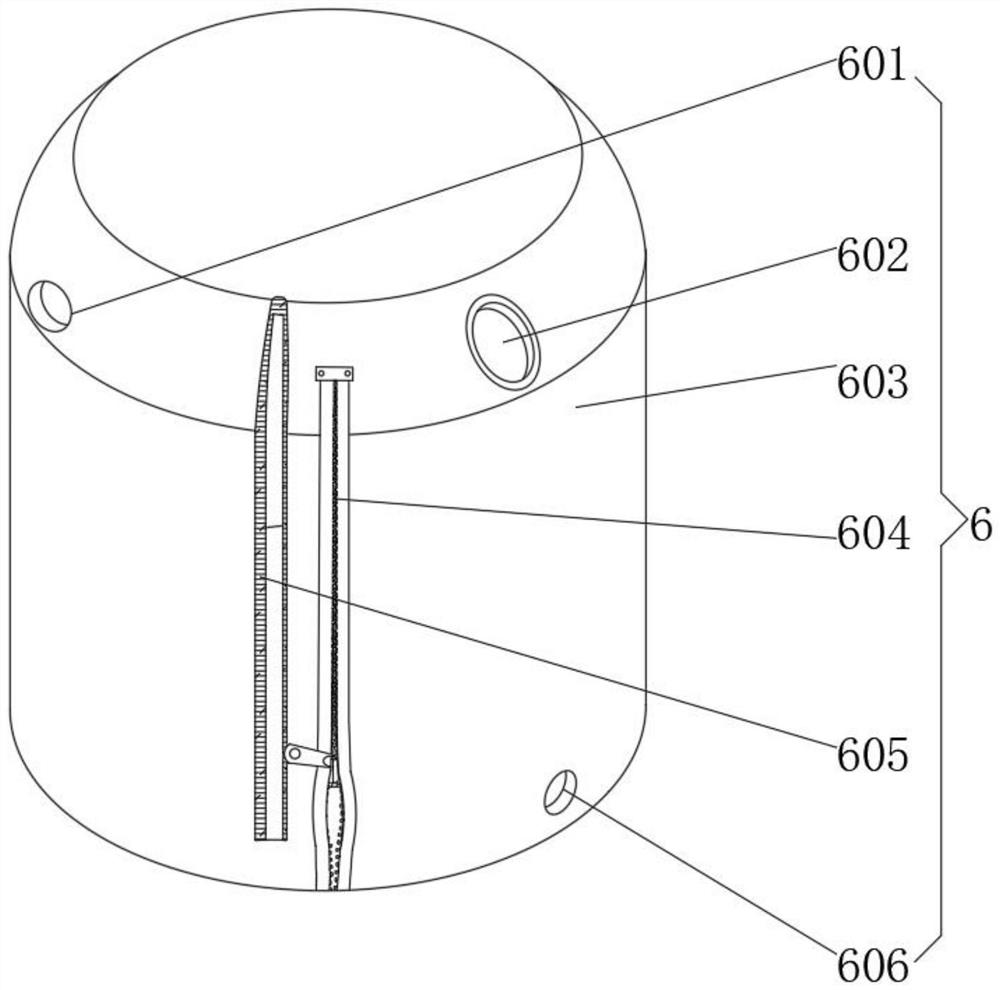

[0036] This embodiment is an embodiment of a heat preservation mechanism for an outlet collector of a vacuum oil filter.

[0037] like figure 1 , 3 As shown, a heat preservation mechanism for an outlet collector of a vacuum oil purifier, the heat preservation mechanism 6 includes a first valve hole 601, a sight glass hole 602, a heat preservation sleeve 603, a zipper 604, a heat preservation material 605 and a second valve hole 606. The overall structure of the sleeve 603 matches the structure of the oil storage tank 1. The first valve hole 601 and the sight glass hole 602 are opened in the upper section of the thermal insulation sleeve 603, and the first valve hole 601 is located on one side of the sight glass hole 602. The second valve hole 601 The hole 606 is opened in the lower section of the heat preservation cover 603 , the zipper 604 is opened on the outer surface of the front end of the heat preservation cover 603 , and the heat preservation cover 603 is opened and cl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap