Boiler desulfurization and denitrification device

A desulfurization and denitrification, boiler technology, applied in the field of desulfurization and denitrification, can solve the problems of insufficient flue gas treatment, unfavorable treatment liquid full absorption, high flue gas flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

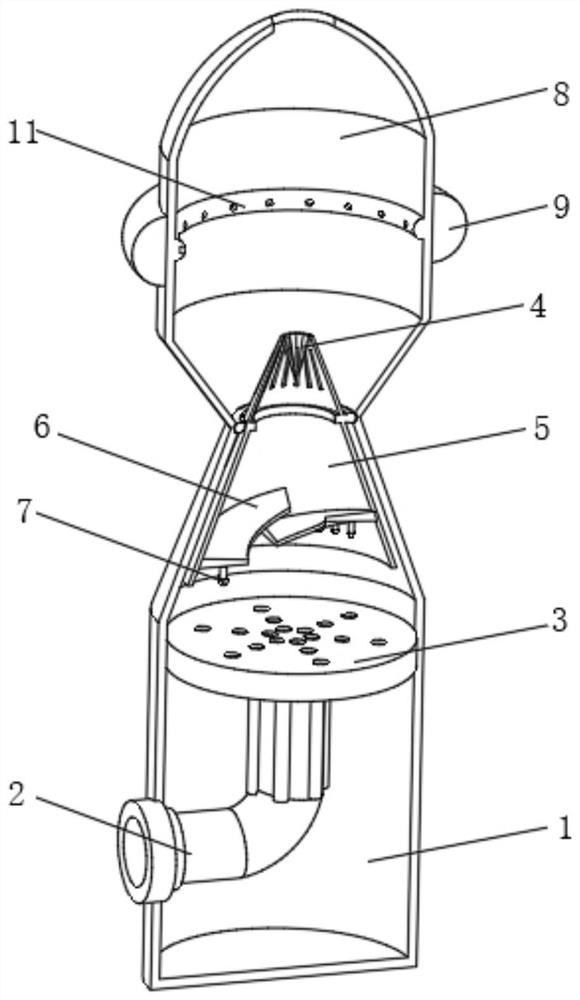

[0036] Such as Figure 1-3 As shown, the present invention provides a technical solution: a boiler desulfurization and denitrification device, including a processing bottom frame 1, and the side of the processing bottom frame 1 near the bottom is fixedly connected with an internal through pipe 2, and the internal through pipe 2 is located at the processing bottom frame 1 One end of the interior is fixedly connected with an adjustment and dredging mechanism 3, and the top of the processing bottom frame 1 is rotatably connected with a dispersing mechanism 4, and the lower part of the dispersing mechanism 4 is fixedly connected with a conduction cone groove 5, and the inner surface of the conduction cone groove 5 near the bottom is uniformly fixedly connected with The buffer fan 6, the bottom surface of the buffer fan 6 is evenly and fixedly connected with the grasping mechanism 7, the top of the processing bottom frame 1 is fixedly connected with the processing top groove 8, and ...

Embodiment 2

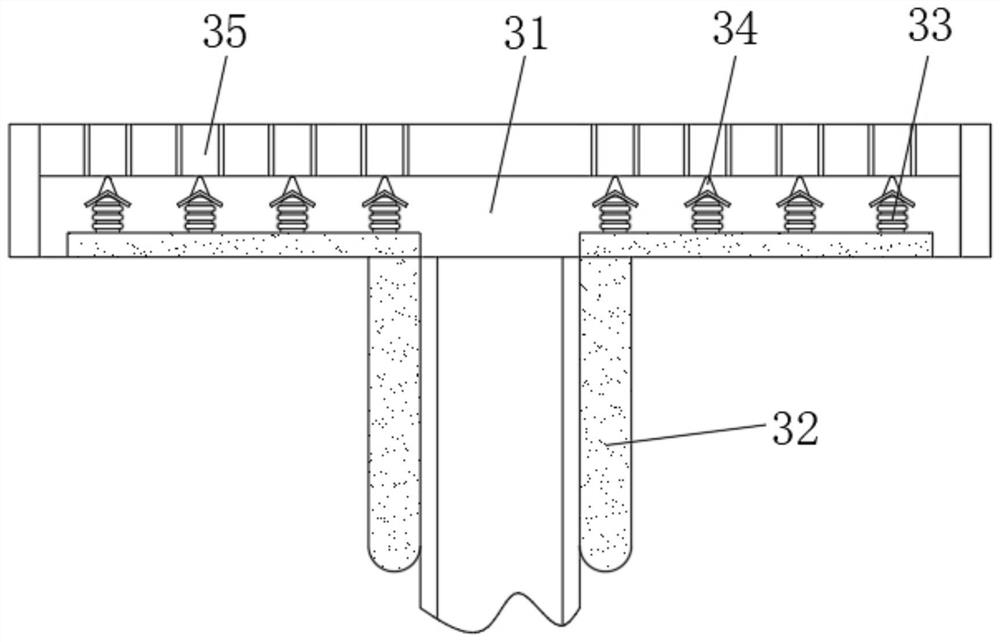

[0041] Such as Figure 4-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a boiler desulfurization and denitrification device, the dispersing mechanism 4 includes a movable slider 41, and the movable slider 41 is connected to the internal test of the bottom frame 1 for rotation, The inner side of the movable slider 41 is fixedly connected with a limiting cone plate 42 , and the surface of the joint between the limiting cone plate 42 and the movable slider 41 is uniformly provided with a liquid guiding port 43 . Most of the sprayed treatment liquid flows to 43 on the surface of 42 to realize the directional flow of the treatment liquid and prevent the treatment liquid from entering the air duct and flowing into the boiler.

[0042] Dispersion passages 44 are uniformly provided on the outer surface of the confinement cone plate 42 , and adjustment movable assemblies 45 are rotatably connected to positions inside the confinement cone ...

Embodiment 3

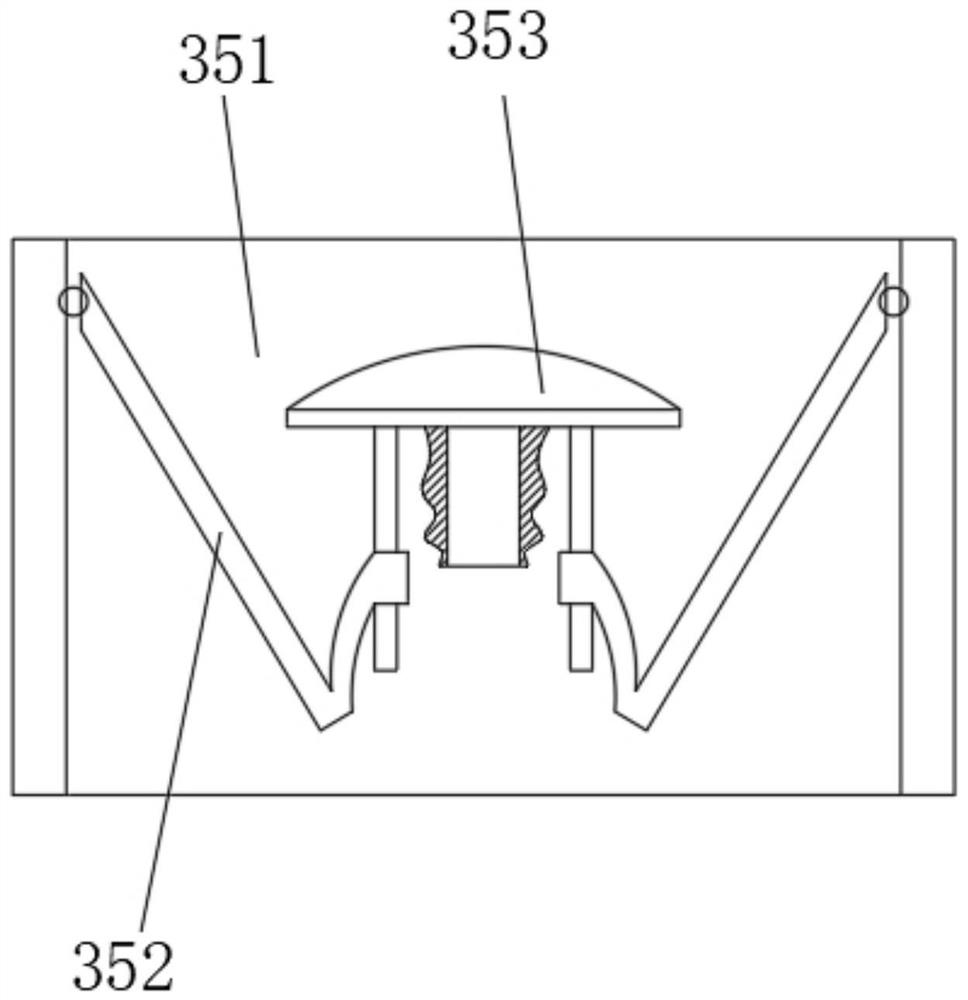

[0046] Such as Figure 7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a boiler desulfurization and denitrification device, the grabbing mechanism 7 includes a limiting top plate 71, and the top of the limiting top plate 71 is fixed to the buffer fan 6 Connecting and restricting the rotation of the bottom of the top plate 71 is connected with a rotating strut 72 , and the bottom surface of the rotating strut 72 is connected with a guiding splint 73 for uniform rotation.

[0047] A magnetic block 74 is fixedly connected to the top of the rotating pole 72 and corresponding to the guide clamping plate 73 , and a grasping filter plate 75 is connected to limit the uniform rotation of the outer side of the top plate 71 . The flow velocity of the flue gas is converted into a rotational force, and through the magnetic repulsion between the filter holes 74 and 75, the periodic up and down swing of the 75 is realized to inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com