Impact tool

A technology of impact tools and anvils, applied in the field of impact tools, can solve problems such as cracks, stress concentration, failure of anvils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

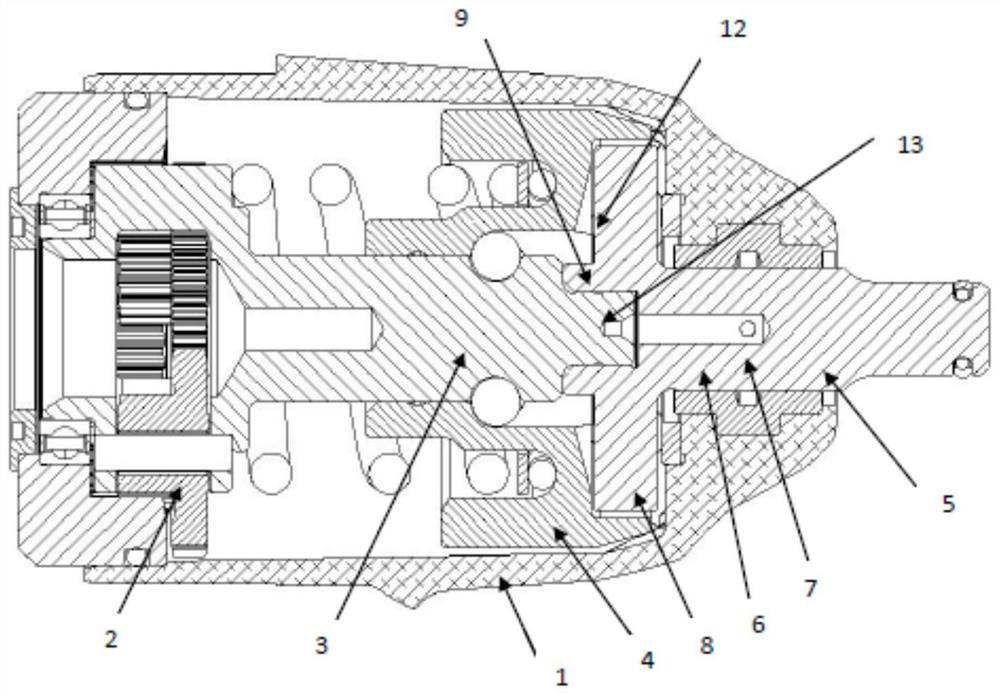

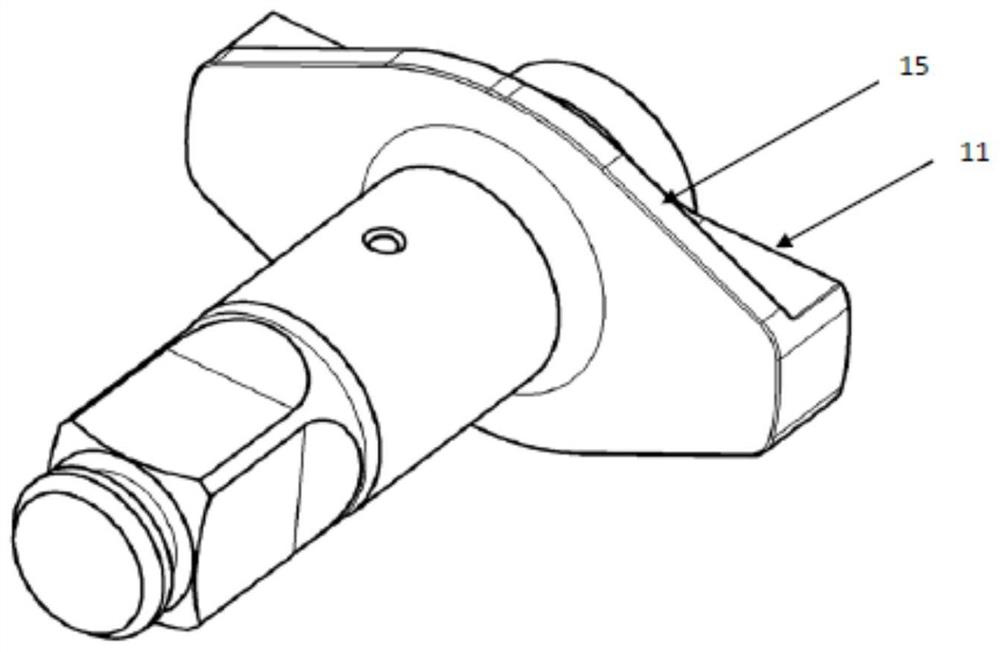

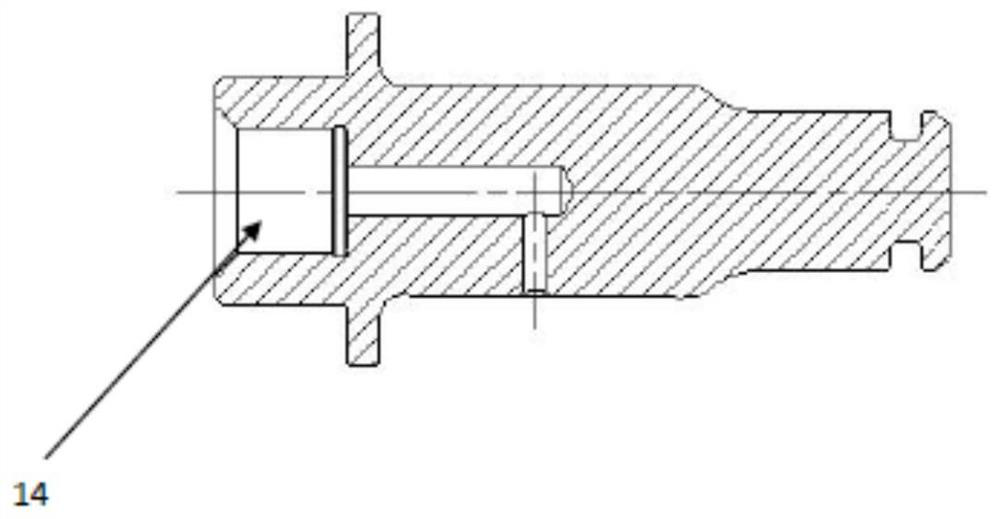

[0021] Below, will refer to Figure 1 to Figure 5 An impact tool and an anvil for the impact tool according to an embodiment of the present invention are described.

[0022] In an exemplary embodiment of the invention, the impact tool is an impact wrench. figure 1 The front end of an impact wrench is shown. The impact tool of the present invention, specifically, an impact wrench 10 includes a housing 1, and a power device (not shown) arranged in the housing is coupled with the power device The gear assembly 2 and the main shaft 3, the hammer assembly 4 coupled with the gear assembly and the main shaft, and the anvil 5 of the present invention. The power unit is preferably an electric motor and is powered by a power source, such as a rechargeable battery or alternating current (not shown). As an alternative, the power unit may be compressed air or hydraulic lines or an air motor driven. The rotation of the power device is decelerated by the gear assembly 2 and then transmitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com