Farmland water returning ditch purification system combining ecological floating bed and iron-carbon micro-electrolysis

An iron-carbon micro-electrolysis and ecological floating bed technology, applied in the field of agricultural non-point source pollution control, can solve the problems of water purification effect decline, filler failure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the purpose and technical solutions of the present invention clearer, the technical solutions of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

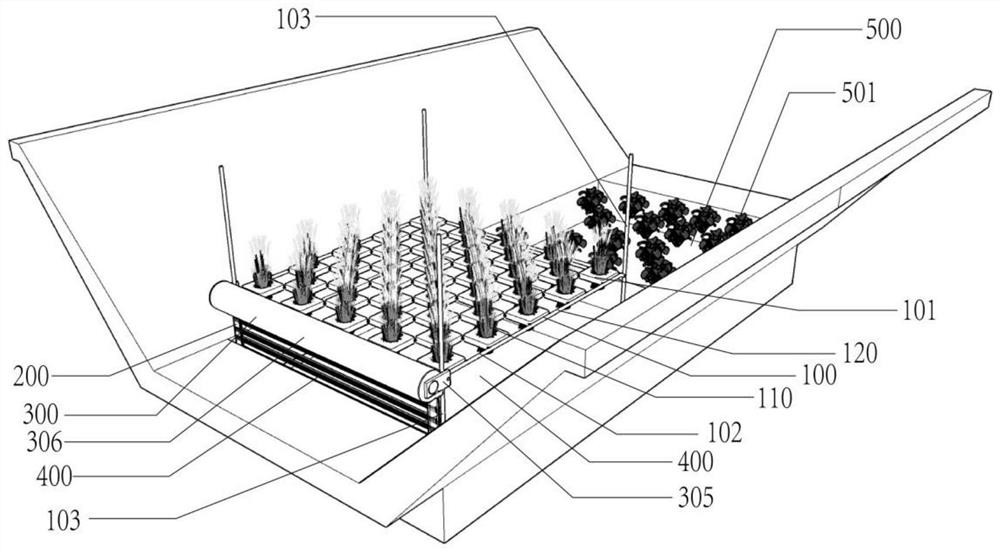

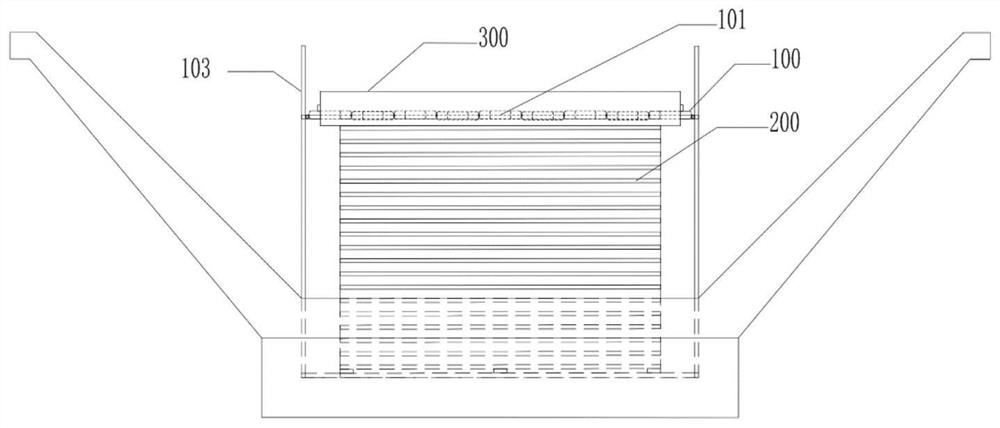

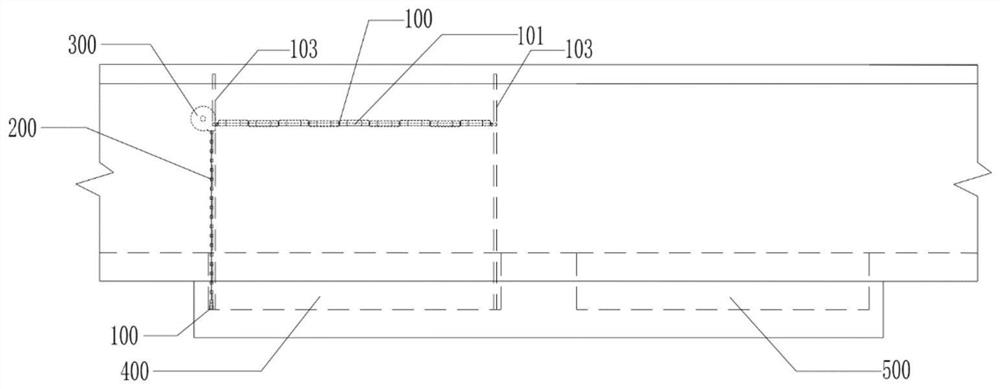

[0033] Such as Figure 1-5 As shown, the farmland ditch purification system combining ecological floating bed and iron-carbon micro-electrolysis includes:

[0034] Floating bed 100, described floating bed 100 comprises floating bed base 102 and a plurality of floating bed planting baskets 101; Floating bed planting basket 101 is detachably arranged on floating bed base 102, planted with plant 110 in the floating bed planting basket 101;

[0035] Support, the support includes four fixed rods 103 vertically arranged in the ditch, the four corners of the floating bed base 102 are respectively fixed with collars, and each collar is movably sleeved on a corresponding fixed rod 103 on;

[0036] An iron-carbon micro-electrolysis mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com