High-calcium homogenized magnesia carbon brick and preparation method thereof

A magnesia-carbon brick and high-calcium technology, which is applied in the field of calcium-containing magnesia-carbon brick and its preparation, can solve problems such as difficult to avoid calcium hydration, high production cost, and short storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

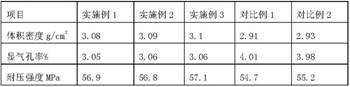

Embodiment 1

[0031] Take high-calcium fused magnesia, flake graphite, phenolic resin, antioxidant and additives for batching according to parts by mass, wherein:

[0032]800 parts of high-calcium fused magnesia, in the total mass parts, 14% of the particle size is 5-3mm, 37% of the particle size is 3-1mm, 49% of the particle size is 1-0.088mm, and the mass percentage of MgO is 95% %, the mass percentage of CaO is 2%;

[0033] 10 parts of flake graphite, the mass percentage composition of flake graphite C is 95%;

[0034] 30 parts of phenolic resin, the phenolic resin is common thermosetting phenolic resin;

[0035] 5 parts of antioxidant, the antioxidant is Si, the particle size is D50=1µm;

[0036] 30 parts of additives, CaO . Al in additives 2 o 3 with CaO .2Al 2 o 3 The mixing ratio is 1:1 and the particle size is 0.5mm.

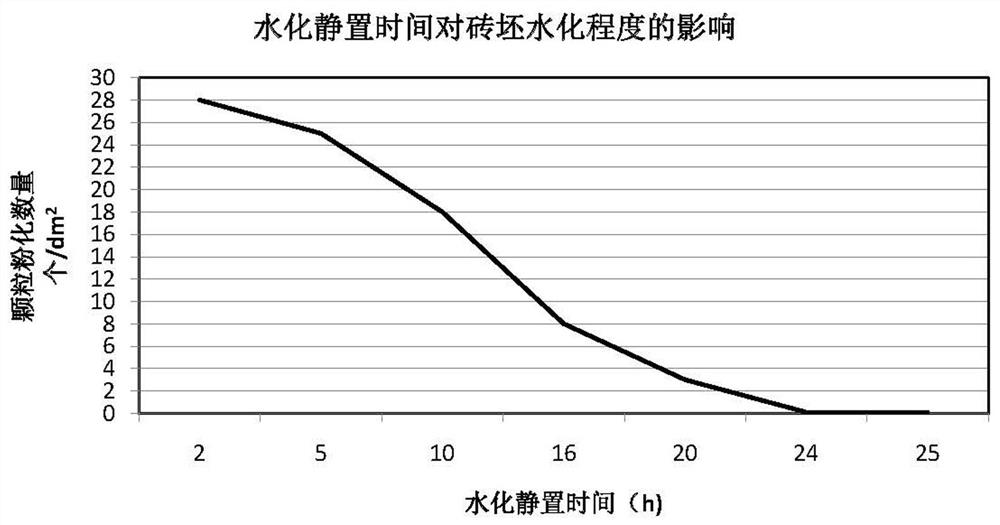

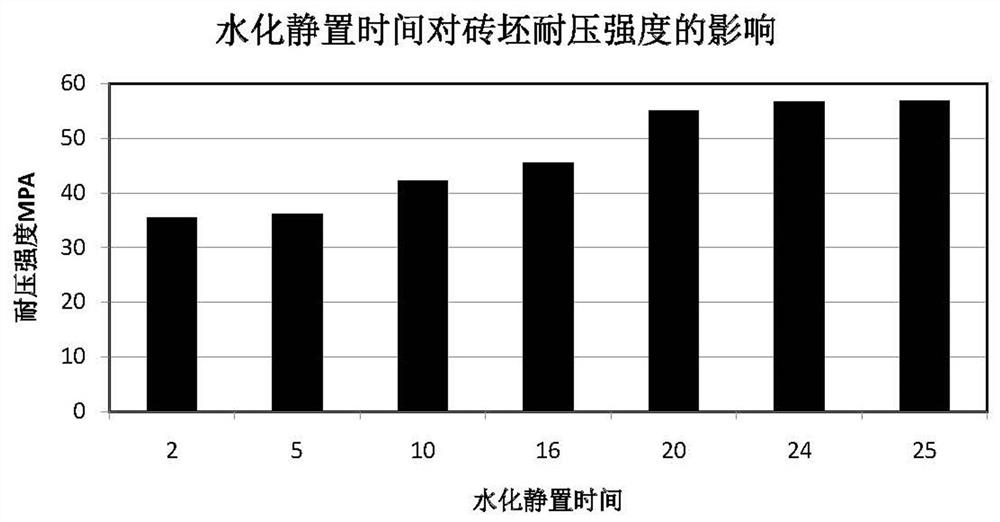

[0037] Break the fused magnesia into 5-0.088mm particle size material and send it to the closed material box, spray water and let it stand for 24 hours, then s...

Embodiment 2

[0047] Take high-calcium fused magnesia, flake graphite, phenolic resin, antioxidant and additives for batching according to parts by mass, wherein:

[0048] 850 parts of high-calcium fused magnesia, in the total mass parts, 16% of the particle size is 5-3mm, 36% of the particle size is 3-1mm, 48% of the particle size is 1-0.088mm, and the mass percentage of MgO is 96% %, the mass percentage of CaO is 3%;

[0049] 40 parts of flaky graphite, the mass percentage composition of flaky graphite C is 97%;

[0050] 30 parts of phenolic resin, the phenolic resin is common thermosetting phenolic resin;

[0051] 15 parts of antioxidant, the antioxidant is silicon nitride, the particle size is D50=1µm;

[0052] 50 parts of additives, CaO . Al in additives 2 o 3 with CaO .2Al 2 o 3 The mixing ratio is 1:1.3, and the particle size is 0.1mm.

[0053] Break the fused magnesia into 5-0.088mm particle size material and send it to a closed material box, spray water and let it stand for ...

Embodiment 3

[0061] Take high-calcium fused magnesia, flake graphite, phenolic resin, antioxidant and additives for batching according to parts by mass, wherein:

[0062] 900 parts of high-calcium fused magnesia, in the total mass parts, 17% of the particle size is 5-3mm, 34% of the particle size is 3-1mm, 49% of the particle size is 1-0.088mm, and the mass percentage of MgO is 97% %, the mass percentage of CaO is 4%;

[0063] 80 parts of flake graphite, the mass percentage composition of flake graphite C is 99%;

[0064] 40 parts of phenolic resin, the phenolic resin is common thermosetting phenolic resin;

[0065] 30 parts of antioxidant, the antioxidant is a mixture of Si, silicon nitride and AL-O-N, the particle size is D50=2µm;

[0066] 80 parts of additives, CaO . Al in additives 2 o 3 with CaO .2Al 2 o 3 The mixing ratio is 1:1.5, and the particle size is 0.045mm.

[0067] Break the fused magnesia into 5-0.088mm particle size material and send it to a closed material box, spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com