Preparation method of high-content tristyrylphenol polyoxyethylene ether ammonium sulfate, and product thereof

A technology of tristyryl phenol and polyoxyethylene ether, which is applied in the field of preparation of high-content tristyryl phenol polyoxyethylene ether ammonium sulfate, and can solve the problems of less post-treatment, difficult reaction control, and high salt content in products , to achieve the effect of increasing active content and good product color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

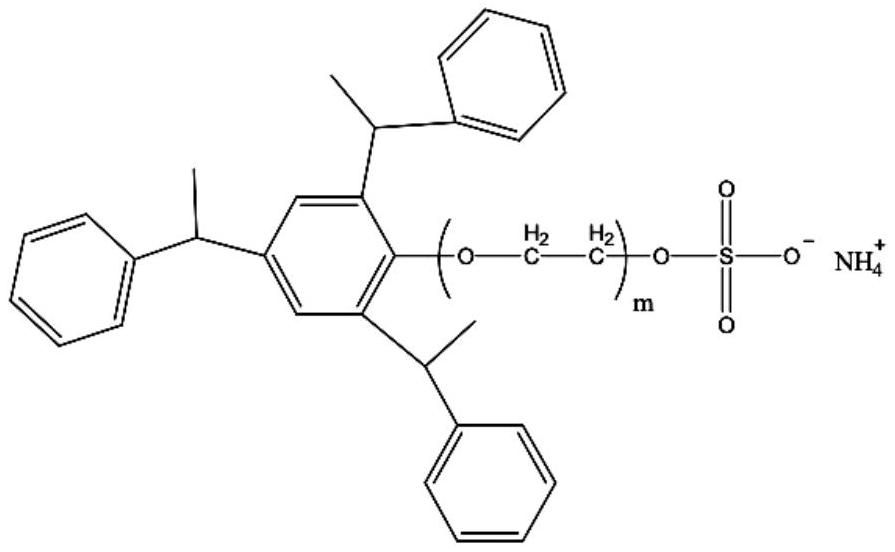

[0030] Step 1. In a 500 ml reaction flask, add 370 grams of 600#B, add 3.5 grams of cyanamide, then add 30 grams of sulfamic acid, and raise the temperature to 90°C for 8 hours. The tristyrylphenol polyoxyethylene ether ammonium sulfate of 600#B, m in its structural formula is 20.

[0031] Step 2, adding monoethanolamine to adjust the pH to 7 to obtain a light yellow product with an anionic active substance content of 91%.

Embodiment 2

[0033] Step 1. In a 500 milliliter reaction flask, add 370 grams of 600#C, add 3.5 grams of cyanamide, then add 24 grams of sulfamic acid, and raise the temperature to 100 ° C for 5 hours. The tristyrylphenol polyoxyethylene ether ammonium sulfate of 600#C, m in its structural formula is 24.

[0034] Step 2, adding diethanolamine to adjust the pH to 7 to obtain a pale yellow product with an anionic active substance content of 90%.

Embodiment 3

[0036] In step 1, 500 milliliters of reaction flasks, add 380 grams of 600#D, add 1.5 grams of guanidine carbonate, then add 20 grams of sulfamic acid, raise the temperature to 110 DEG C and react for 3 hours. The tristyrylphenol polyoxyethylene ether ammonium sulfate of 600#D, m in its structural formula is 30.

[0037] Step 2, adding triethanolamine to adjust the pH to 7 to obtain a light yellow product with an anionic active substance content of 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com