Rubber-plastic blended composite material of polyester elastomer toughened and modified carbon dioxide-based plastic, and preparation method thereof

A polyester elastomer, carbon dioxide technology, applied in the field of polymer materials, can solve problems such as obstruction, high brittleness, and insufficient toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of polyester elastomer:

[0038] Raw materials and consumption used in table 1. embodiment 1

[0039]

[0040]

[0041] In a 100ml four-necked bottle, add 1,3-PDO, 1,4-BDO, SuA, SeA, IA according to the amount in Table 1, and put the mixture under N 2 Stir mechanically under atmosphere and heat to 180°C, and keep at 180°C for 2h. Then cool to room temperature, add 0.1wt% tetrabutyl titanate as a catalyst, then gradually increase the temperature to 220°C, pre-condense at -0.06MPa for 1 hour, and then polycondense at -0.1MPa until the product has a climbing effect. Small molecules such as propylene glycol and butanediol produced in the transesterification reaction were distilled under reduced pressure, and finally the product bio-based polyester PPBSIS was obtained.

[0042] Preparation of polyester elastomer modified carbon dioxide-based plastics:

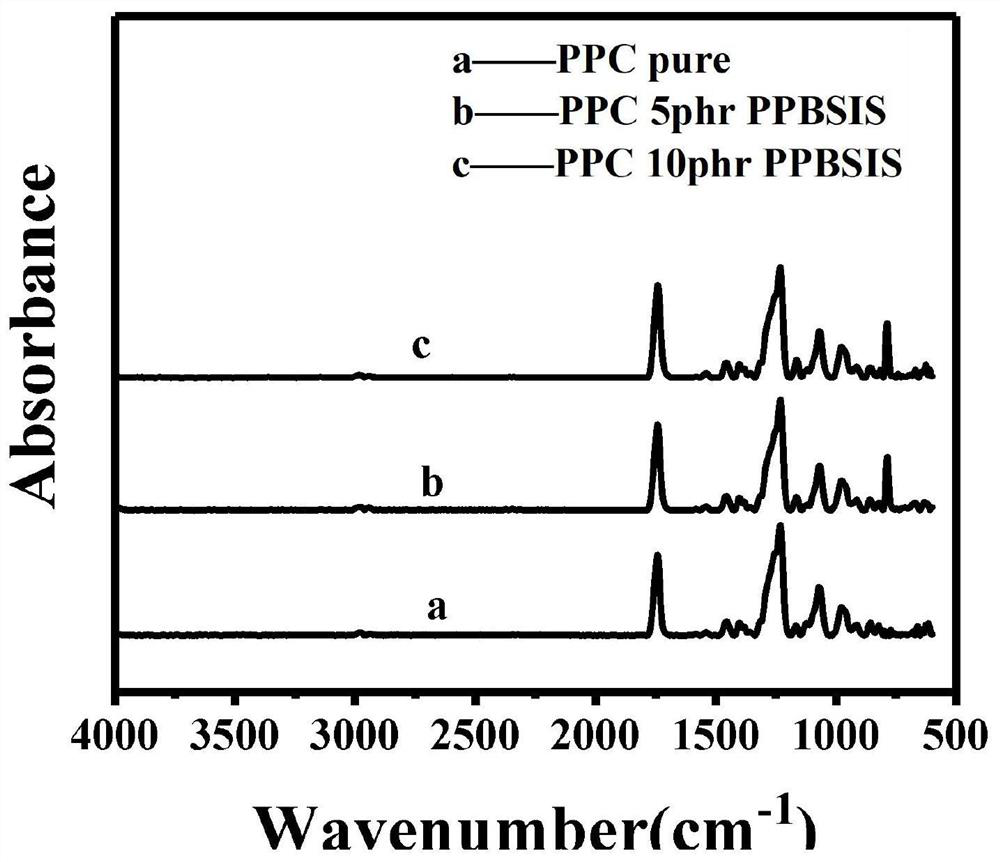

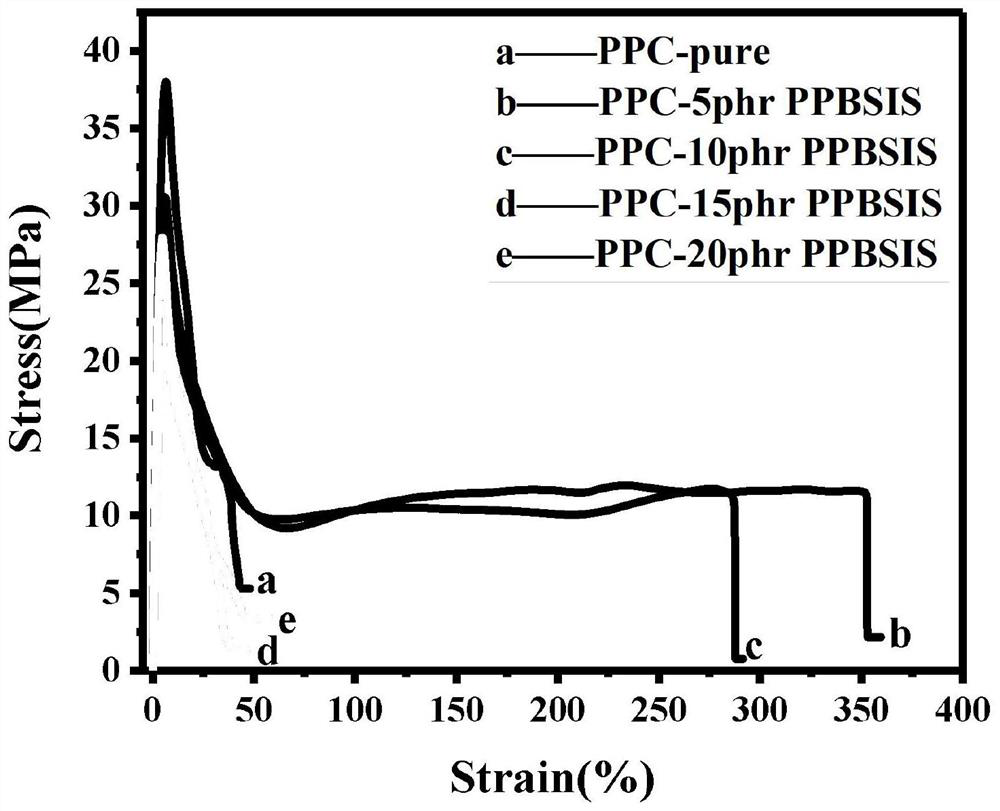

[0043] The bio-based polyester PPBSIS for toughening is obtained from the first step of the synthesis ...

Embodiment 2

[0045] Preparation of polyester elastomer:

[0046] Raw materials and consumption used in table 2. embodiment 2

[0047]

[0048]

[0049] In a 100ml four-necked bottle, add 1,2-PDO, 1,4-BDO, and AA according to the dosage in Table 2. Put the mixture in N 2 Mechanically stirred and heated to 160°C under atmosphere, and kept at 160°C for 2h. Then the temperature was raised to 180°C and kept at 180°C for 2h. Then cool to room temperature, add 0.2wt% tetrabutyl titanate as a catalyst, then gradually increase the temperature to 220°C, pre-condense at -0.06MPa for 1 hour, and then polycondense at -0.1MPa until the product has a climbing effect. Small molecules such as 1,2-propanediol and butanediol produced in the transesterification reaction were distilled under reduced pressure, and finally the product bio-based polyester PPBA was obtained. Since the obtained product is a saturated system rubber without double bonds, the color of the product is relatively light, and the...

Embodiment 3

[0053] Preparation of polyester elastomer:

[0054] Raw materials and consumption used in table 3. embodiment 3

[0055]

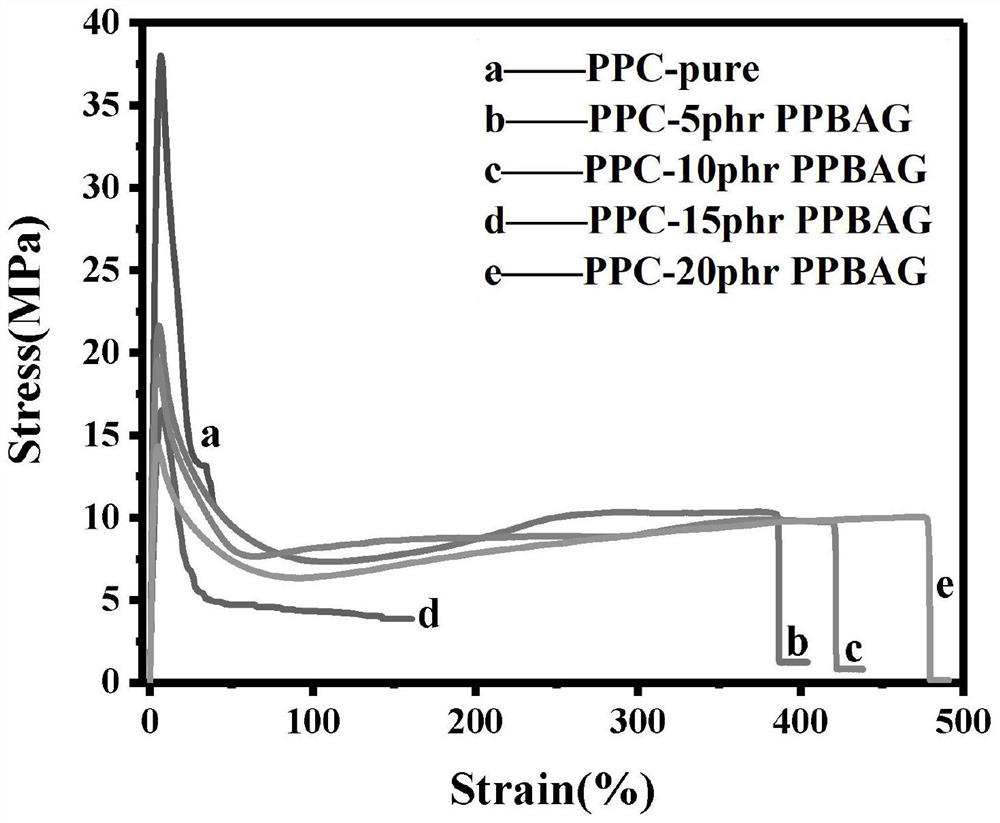

[0056] In a 100ml four-necked bottle, add 1,2-PDO, 1,4-BDO, AA, and Gl according to the dosage in Table 3. Put the mixture in N 2 Mechanically stirred and heated to 160°C under atmosphere, and kept at 160°C for 2h. Then the temperature was raised to 180°C and kept at 180°C for 2h. Then cool to room temperature, add 0.2wt% tetrabutyl titanate as a catalyst, then gradually increase the temperature to 220°C, pre-condense at -0.06MPa for 1 hour, and then polycondense at -0.1MPa until the product has a climbing effect. Small molecules such as 1,2-propanediol and butanediol produced in the transesterification reaction were distilled under reduced pressure, and finally the product bio-based polyester PPBAG was obtained. Since the obtained product is a saturated system rubber without double bonds, the color of the product is relatively light, and the color ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com