Process method for preparing environment-friendly color fading controllable ink

An ink and environmentally friendly technology, applied in the field of environmentally friendly and fade-controllable ink preparation, can solve problems such as poor user experience, poor fading effect, and poor durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

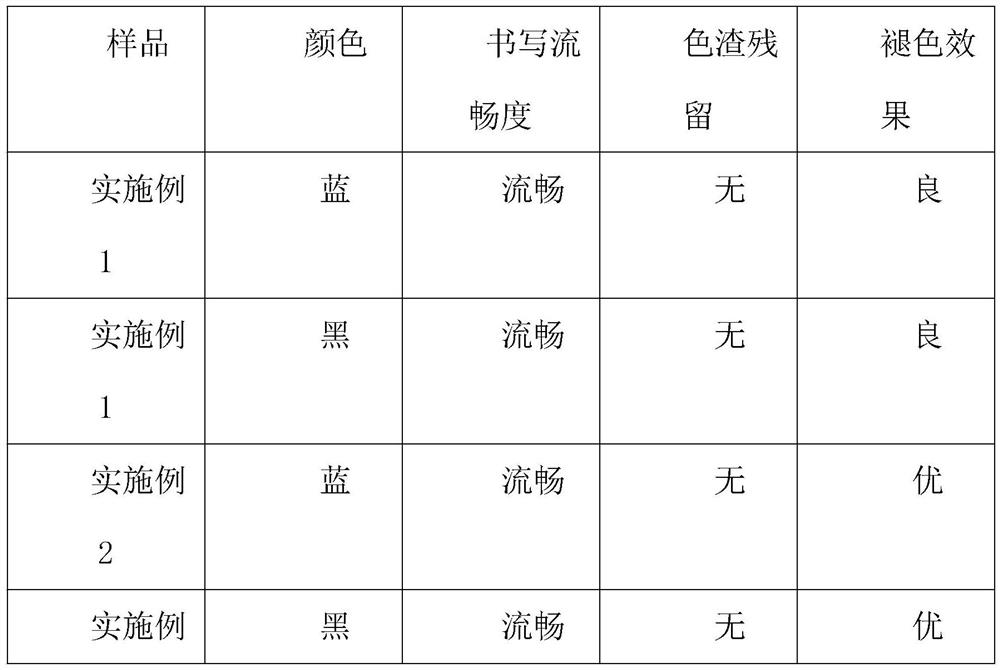

Embodiment 1

[0017] Embodiment 1: An environmentally friendly and fade-controllable ink, including the following raw materials in parts by mass: 15 parts of pure water, 70 parts of ethanol, 20 parts of colorant, 20 parts of sodium alginate, 20 parts of sodium carbonate, 205 parts of sodium acetate, 5 parts of gum arabic, 5 parts of film forming agent, 1 part of active agent, 1 part of glycerin, 1 part of essence.

[0018] A preparation method of environmentally friendly fade controllable ink, comprising the following steps:

[0019] S1: Dissolve an appropriate amount of sodium alginate, sodium carbonate and sodium acetate in purified water, add ethanol, and stir to obtain an alkaline liquid. The preparation method of the alkaline liquid is: add sodium alginate, sodium carbonate and sodium acetate into the reaction kettle , add purified water at the same time, react in a high-speed homogenizer at 12000-14000rpm for 1-2 minutes, then add ethanol and continue stirring for 4-12 hours to obtain...

Embodiment 2

[0024] Embodiment 2: An environmentally friendly and fade-controllable ink, including the following raw materials in parts by mass: 20 parts of pure water, 80 parts of ethanol, 30 parts of colorant, 25 parts of sodium alginate, 25 parts of sodium carbonate, 25 parts of sodium acetate, 10 parts of gum arabic, 10 parts of film forming agent, 5 parts of active agent, 5 parts of glycerin, 5 parts of essence.

[0025] A preparation method of environmentally friendly fade controllable ink, comprising the following steps:

[0026] S1: Dissolve an appropriate amount of sodium alginate, sodium carbonate and sodium acetate in purified water, add ethanol, and stir to obtain an alkaline liquid. The preparation method of the alkaline liquid is: add sodium alginate, sodium carbonate and sodium acetate into the reaction kettle , add purified water at the same time, react in a high-speed homogenizer at 12000-14000rpm for 1-2 minutes, then add ethanol and continue stirring for 4-12 hours to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com