Self-curling preparation method and application of hollow graphene fibers

A graphene fiber, self-crimping technology, applied in the direction of hollow filament manufacturing, fiber processing, fiber chemical characteristics, etc., can solve the problems of graphene fiber mechanical strength deterioration, failure to achieve efficiency and continuity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

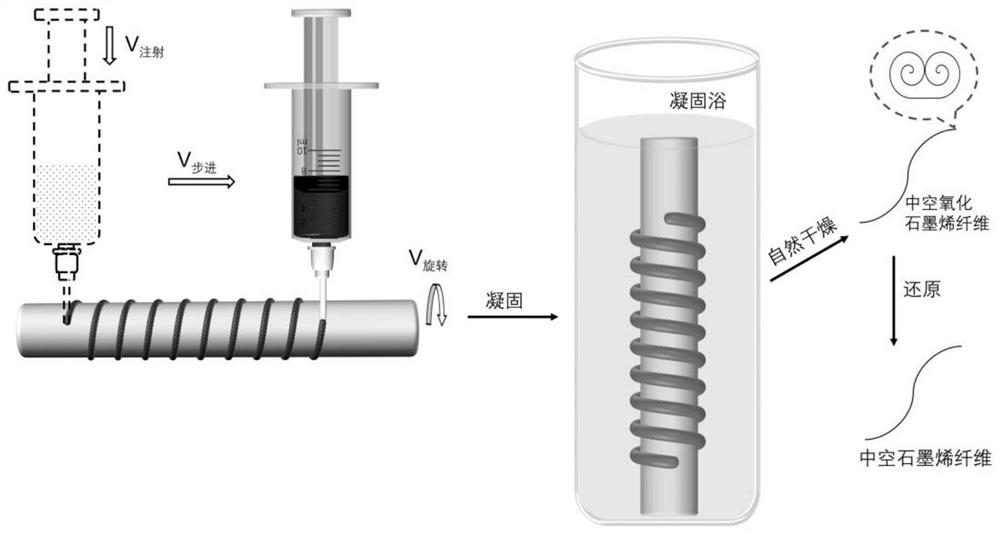

[0027] A kind of self-curling preparation method of hollow graphene fiber, concrete operation steps are as follows:

[0028] (1) Weigh 20g of commercial graphene oxide slurry with a mass concentration of 0.94% and place it in a beaker, add 0.2ml of ammonia water with a mass concentration of 25-28% to promote the flocculation effect of the slurry, heat at 100°C and stir for 20 minutes to concentrate To double the concentration, then pack into a 10ml syringe, inject and print on the rotating roller (roller outer diameter 29mm, rotation speed 150 rpm) with a 19G needle (inner diameter 0.72mm) at a speed of 36mm / min, and Stepping while printing, the stepping speed is 100mm / min, to obtain gel-like graphene oxide fibers;

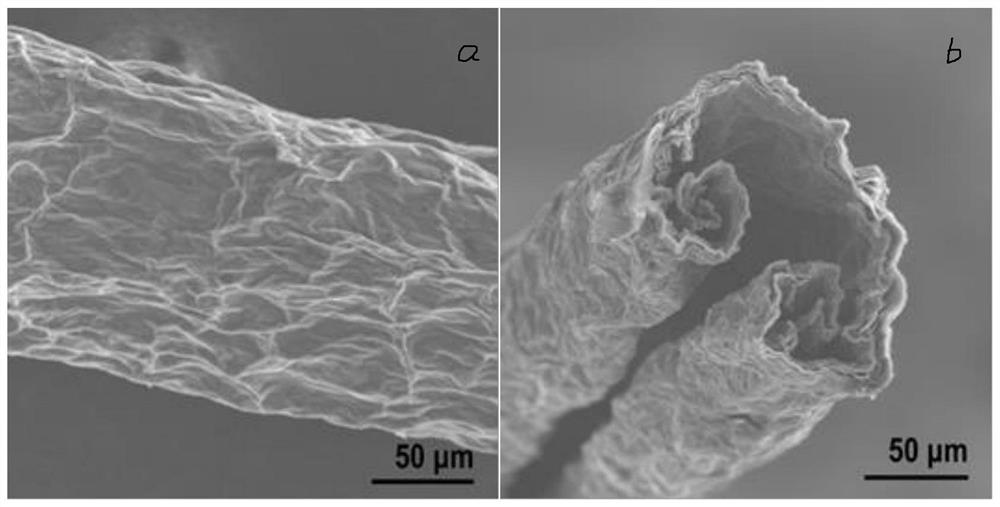

[0029] (2) Soak the gelatinous graphene oxide fiber obtained in step (1) together with the roller into an ethanol solution (99.7% ethanol volume concentration) and solidify for 5 minutes, take it out, and obtain a ribbon-shaped graphene oxide fiber;

[0030] (3) ...

Embodiment 2

[0033] A kind of self-curling preparation method of hollow graphene fiber, concrete operation steps are as follows:

[0034] (1) Weigh 20g of commercial graphene oxide slurry with a mass concentration of 0.94% and place it in a beaker, add 0.2ml of ammonia water with a mass concentration of 25-28% to promote the flocculation effect of the slurry, heat at 100°C and stir for 20 minutes to concentrate To double the concentration, then pack into a 10ml syringe, inject and print on the rotating roller with a 16G needle (1.15mm inner diameter) at a speed of 50mm / min (the outer diameter of the roller is 29mm, the rotation speed is 150 rpm, the roller The diameter is 29mm), and stepping while printing, the stepping speed is 100mm / min, to obtain gel-like graphene oxide fibers;

[0035] (2) Soak the gel-like graphene oxide fiber obtained in step (1) together with the roller into an ethanol solution (ethanol volume concentration ≥ 95%) and solidify for 5-10 minutes, take it out, and obta...

Embodiment 3

[0039] A kind of self-curling preparation method of hollow graphene fiber, concrete operation steps are as follows:

[0040] (1) Weigh 20g of commercial graphene oxide slurry with a mass concentration of 0.94% and place it in a beaker, add 0.2ml of ammonia water with a mass concentration of 25-28% to promote the flocculation effect of the slurry, heat at 100°C and stir for 20 minutes to concentrate To double the concentration, then pack into a 10ml syringe, use a 22G needle (inner diameter 0.4mm) to inject and print on a rotating roller (roller outer diameter 29mm, rotation speed 150 rpm) at a speed of 36mm / min, and Stepping while printing, the stepping speed is 100mm / min, to obtain gel-like graphene oxide fibers;

[0041] (2) Soak the gel-like graphene oxide fiber obtained in step (1) together with the roller into an ethanol solution (ethanol volume concentration ≥ 95%) and solidify for 3-5 minutes, take it out, and obtain ribbon-shaped graphene oxide fiber;

[0042] (3) pe...

PUM

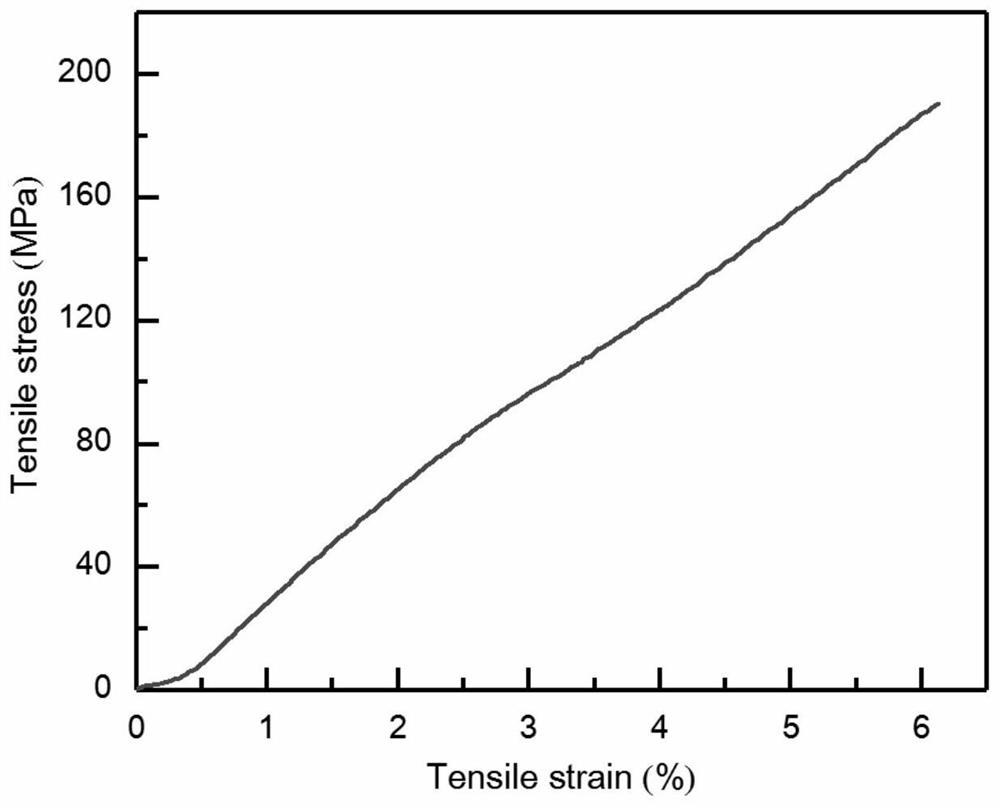

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com