Planetary transmission based on magneto-rheological gear shifting

A planetary transmission and magneto-rheological fluid technology, applied in the field of vehicle transmission, can solve the problems of increasing the burden of lubrication and heat dissipation, increasing the weight and volume of the transmission device, and the large torque of the belt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

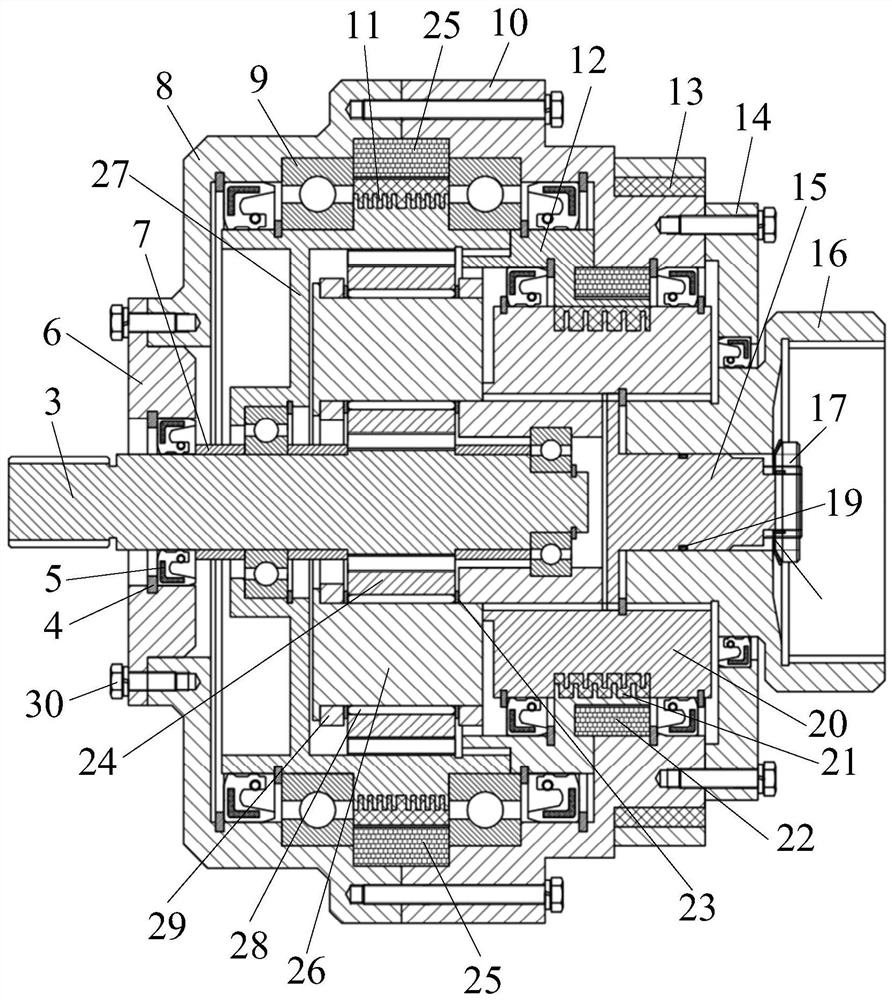

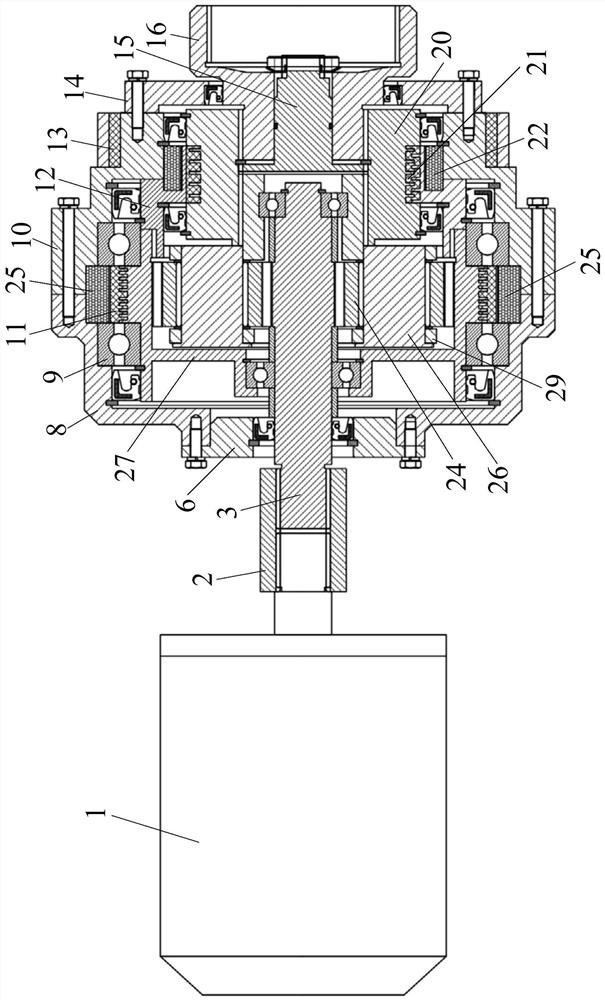

[0036] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0037] The embodiment of the present invention provides a planetary transmission based on magnetic current shift gear, the internal structure of the planetary transmission can be referred to figure 1 , the assembly structure of the planetary transmission and drive motor 1 can refer to figure 2 , the planetary transmission includes a case, a sun gear shaft 3, a first magneto-rheological fluid 11, a ring gear output sleeve 12, a locking sleeve 15, an output gear sleeve 16, a planet carrier output sleeve 20, a first coil 25, a second magnetic Rheological fluid 21, second coil 22, planetary gear 24, planetary gear shaft 26, ring gear 27 and planet carrier 29;

[0038] The sun gear shaft 3 is installed in the box, and one end is connected to the output shaft of the driving motor 1 outside the box; the sun gear shaft 3 is arranged in the horizontal direction, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com