Energy tower for drying flue gas of gas-fired boiler and boiler flue gas drying method

A gas-fired boiler and energy tower technology, which is applied in the field of energy tower and boiler flue gas drying, gas-fired boiler flue gas drying, and can solve the problems that flue gas pipelines are prone to corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

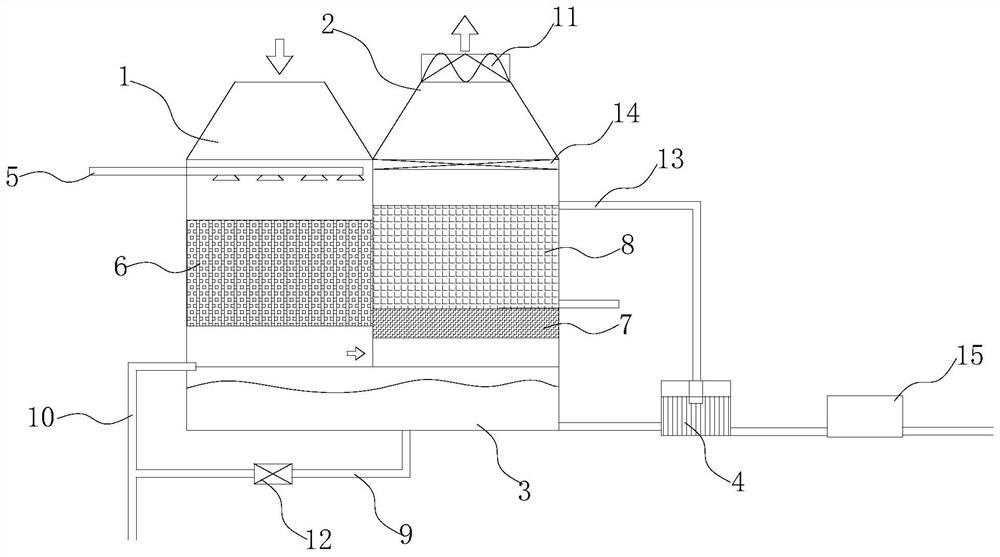

[0026] combine Figure 1 to Figure 4 As shown, the specific implementations of an energy tower for drying gas-fired boiler flue gas and a method for drying boiler flue gas provided by the present invention will be described.

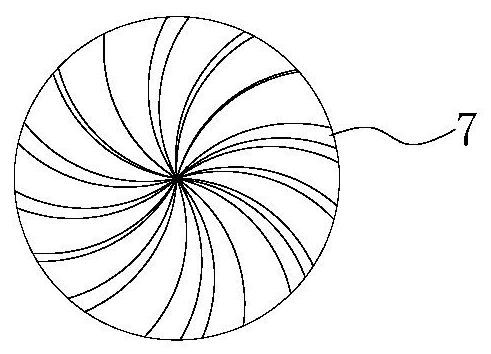

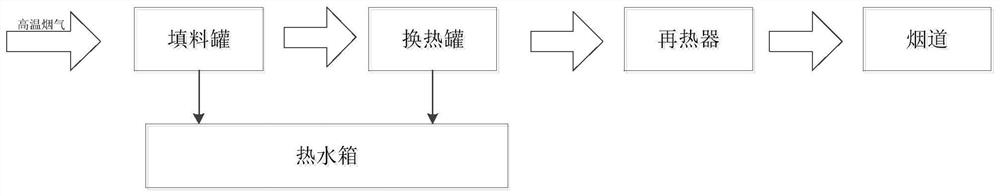

[0027] An energy tower for drying flue gas from a gas-fired boiler, comprising a stuffing tank 1, a heat exchange tank 2, a hot water tank 3 and a heat pump unit 4, the stuffing tank 1 and the heat exchange tank 2 cooperate to cool the high-temperature flue gas and recover the flue gas The water and heat in the air go to the hot water tank, and the hot water tank sends the hot water to the heating equipment through the heat pump unit to realize the reuse of the waste heat of the flue gas.

[0028] The hot water tank is arranged under the stuffing tank 1 and the heat exchange tank 2, and the stuffing tank 1 and the heat exchange tank 2 are arranged adjacent to each other, so that the low-temperature flue gas after heat exchange in the stuffing tank 1 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com