Efficient drying and filtering device for flue gas sampling

A filtering device and high-efficiency technology, applied in the field of high-efficiency drying and filtering devices for flue gas sampling, can solve the problems of large body cavity, insufficient water vapor absorption of discolored silica gel, and exceeding the standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

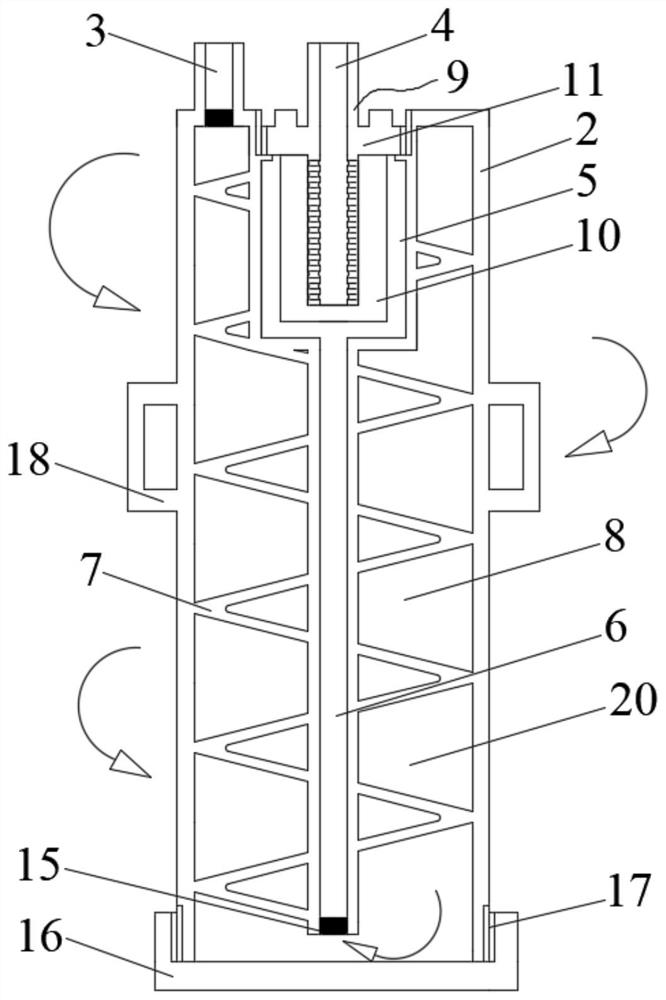

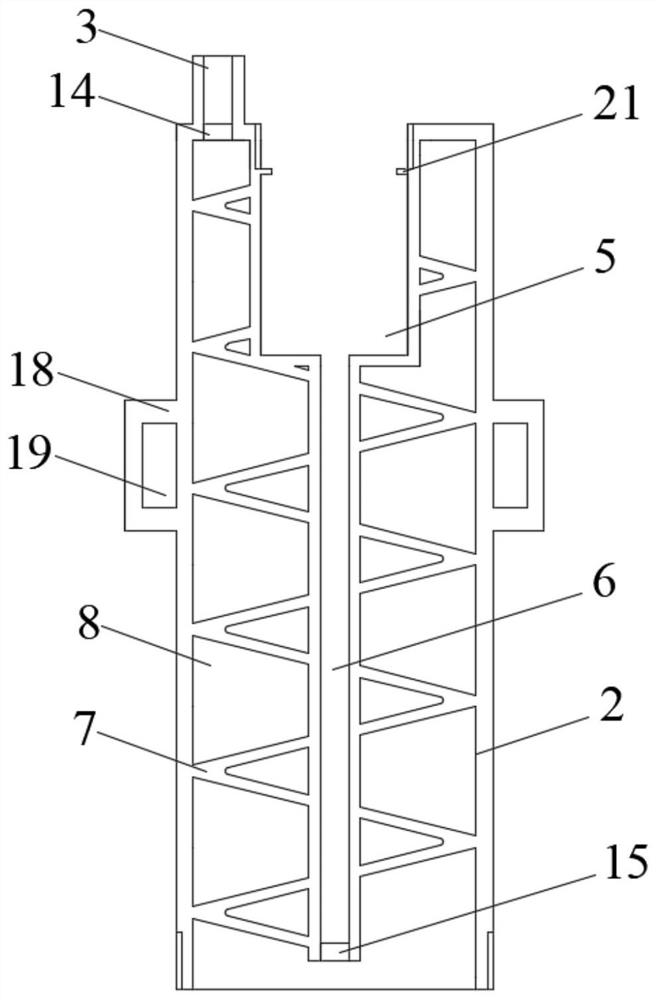

[0021] Such as Figure 2 to Figure 5 As shown, a high-efficiency drying and filtering device for flue gas sampling of the present invention includes a cylindrical drying barrel 2, and the drying barrel 2 is provided with an air inlet 3 and an air outlet 4, and the air outlet 4 is connected to a flue gas sampler Or dust sampler (not shown in the figure), drying barrel 2 is built-in desiccant (not shown in the figure), and desiccant adopts color-changing silica gel, and drying barrel 2 tops are provided with mounting groove 5, and hollow tube 6 After passing through the installation groove 5, it extends into the inside of the drying barrel body 2, and a continuous spiral baffle 7 is provided between the hollow tube 6 and the inner wall of the drying barrel body 2, so that the inner cavity of the drying barrel body 2 is connected to the air inlet 3 The spiral cavity 8 is connected, and the filter element assembly 9 is installed in the installation groove 5. The filter element ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com