Preparation method of composite insulator of hard material layer reinforced core rod

A technology for composite insulators and hard materials, which is applied in the direction of insulators, electrical components, circuits, etc., and can solve problems such as reducing the creepage distance of composite insulators, arc discharge, and exposed mandrels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

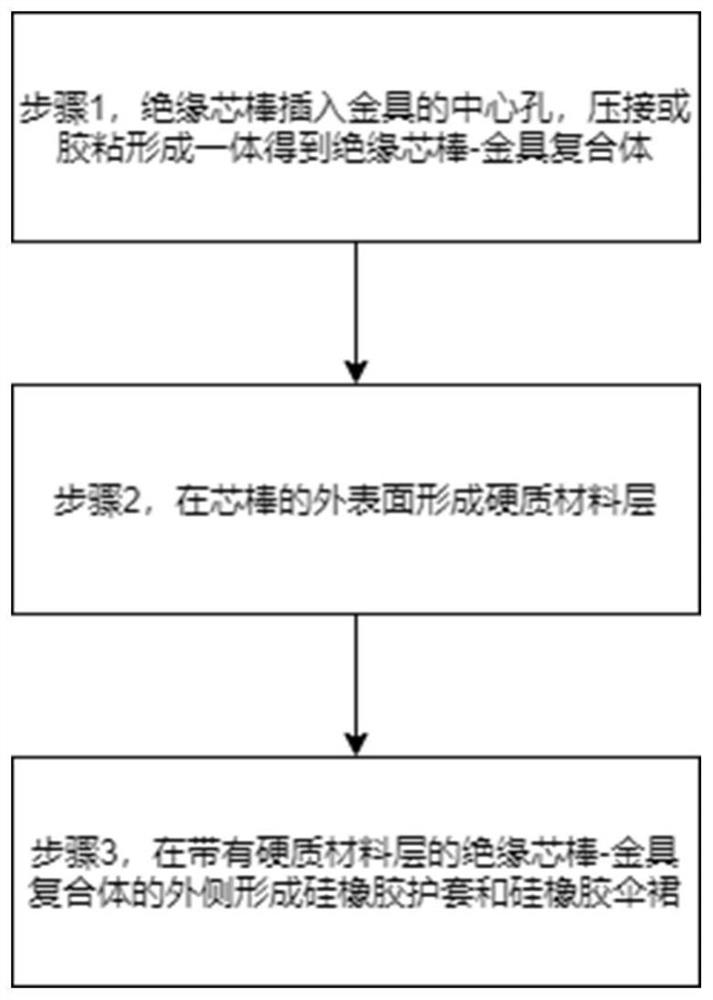

[0033] The application will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present application.

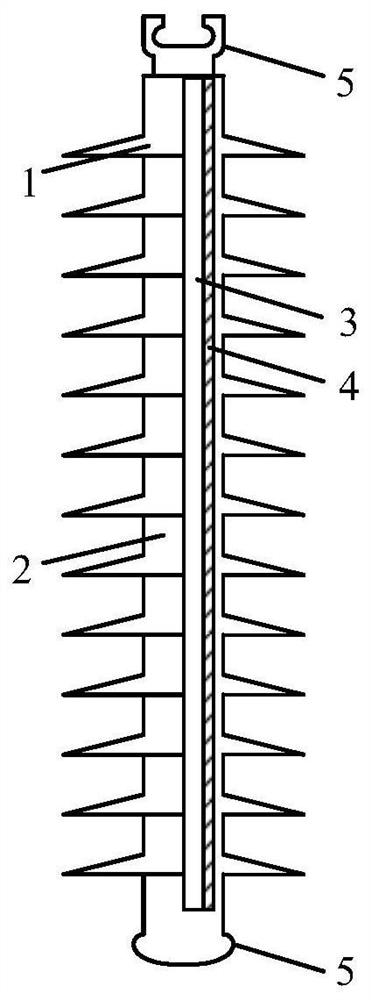

[0034] Such as figure 1 As shown, the composite insulator of the hard material layer reinforced core rod of the present invention includes a silicone rubber shed 1 , a silicone rubber sheath 2 , a core rod 3 , a hard material layer 4 and fittings 5 .

[0035] The mandrel 3 is located at the innermost part of the composite insulator and is wrapped with a hard material layer 4 . The mandrel 3 is the bearing part of the mechanical load of the composite insulator and the main part of the internal insulation. It is made of glass fiber and epoxy resin and has excellent mechanical strength, insulation performance and long-term stability.

[0036] The hard material layer 4 is wrapped on the outside of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com