Treatment method and device for solid waste

A technology of solid waste and treatment method, applied in the field of solid waste treatment, can solve problems such as environmental pollution, and achieve the effects of less environmental damage, simple operation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

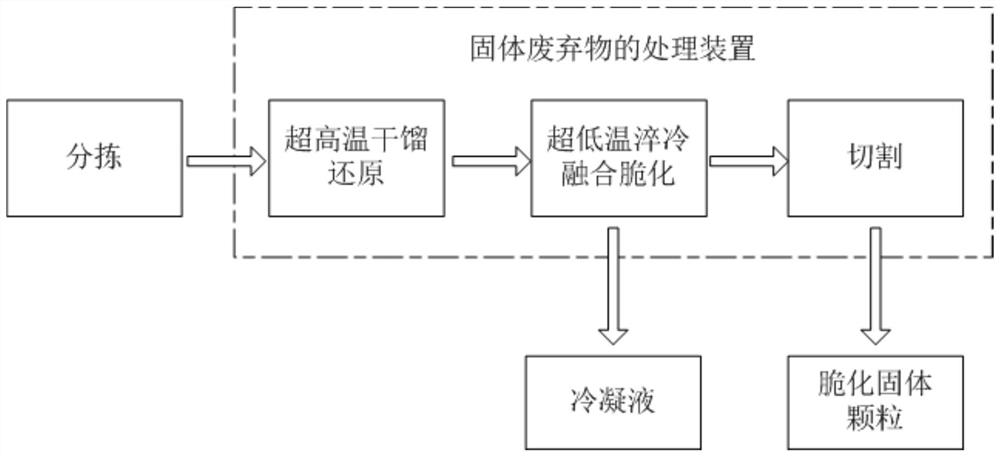

[0027] like figure 1 As shown, the method for treating solid waste disclosed in this embodiment includes the following steps:

[0028] Step 1: take solid waste and place the solid waste in a closed reaction chamber 15;

[0029] Step 2: Heat the reaction chamber 15 until the temperature in the reaction chamber 15 reaches 1300-1800 degrees Celsius, stop the heating and keep the heat for 18-20 hours, and conduct sufficient dry distillation reduction treatment on the solid waste through the high temperature in the reaction chamber 15 to obtain a stable state and balance Mixed gases, vapors and solid reactants of the combined components;

[0030] Step 3: After the reaction chamber 15 is cooled to the preset temperature, liquid nitrogen is injected into the reaction chamber 15, and the reaction chamber is rapidly cooled by the liquid nitrogen to avoid the generation of dioxins, and the mixed gas, steam and solid reactants obtained in step 2 are subjected to Low temperature quenchi...

Embodiment 2

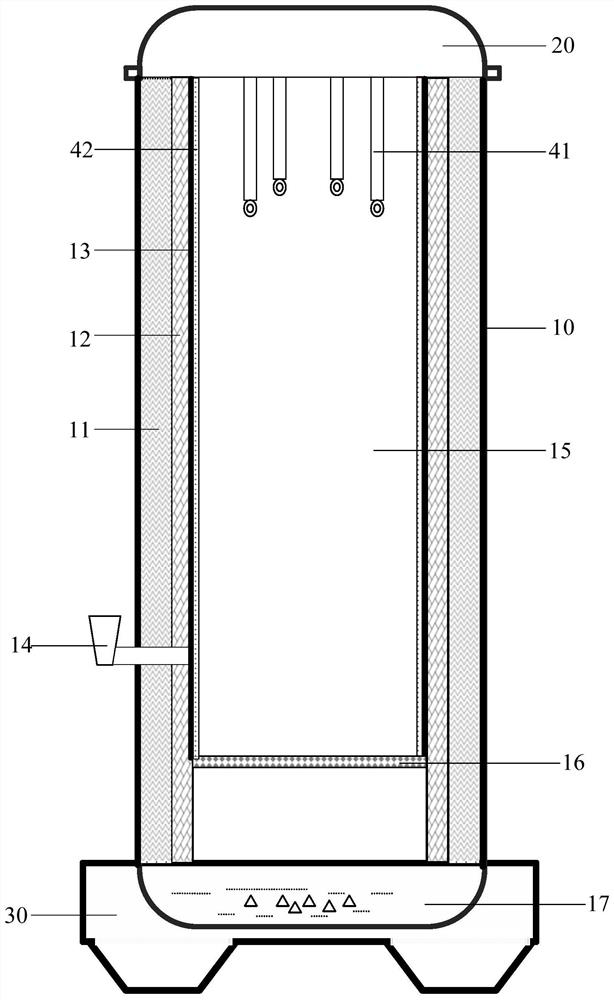

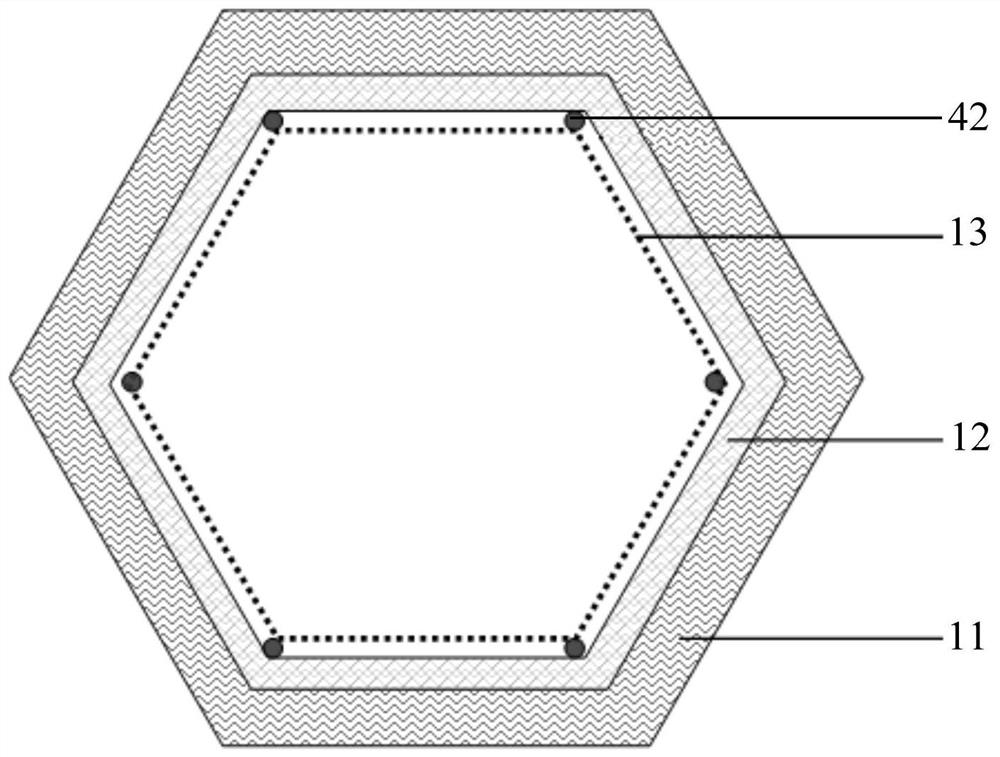

[0049] like Figure 2-3 As shown, this embodiment also discloses a solid waste treatment device, which is used to realize the solid waste treatment method described in Embodiment 1, including:

[0050] The reaction kettle includes a kettle body 10 and a kettle cover 20, and the kettle body 10 is provided with a reaction chamber 15 and a feed port, an injection port 14 and a discharge port communicated with the reaction chamber 15; the reaction The chamber 15 is used for solid waste treatment, the feed port is sealed with the kettle cover 20, a valve is installed at the discharge port, and an external injection device is connected to the injection port 14;

[0051] a heating assembly, which is installed in the reaction chamber 15 of the kettle body 10 and is suitable for heating the reaction chamber 15;

[0052] A thermometer, which is installed in the reaction chamber 15 of the kettle body 10 and located on the periphery of the injection port 14 , and is suitable for detectin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com