Electrical control method for hybrid power rail car

A hybrid and electrical control technology, applied in hybrid vehicles, electric vehicle charging technology, battery/fuel cell control devices, etc., can solve the problem that the catenary and the engine group cannot supply power at the same time, the intermediate DC voltage cannot be adjusted, and the Reduced power operation of the engine, etc., to avoid poor braking performance or failure, ensure life, health and safety, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

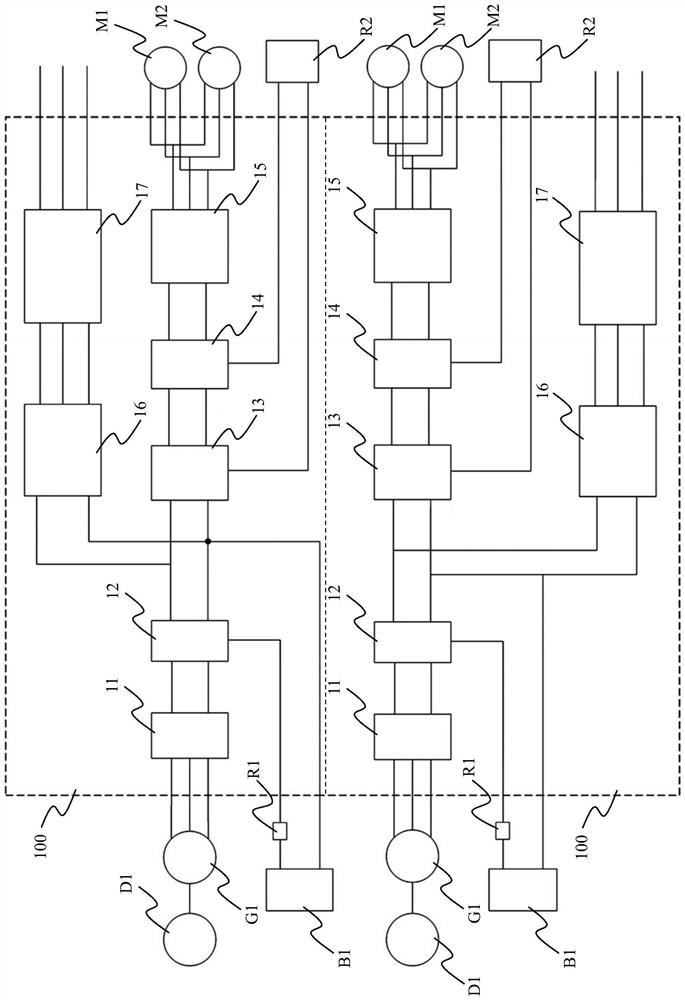

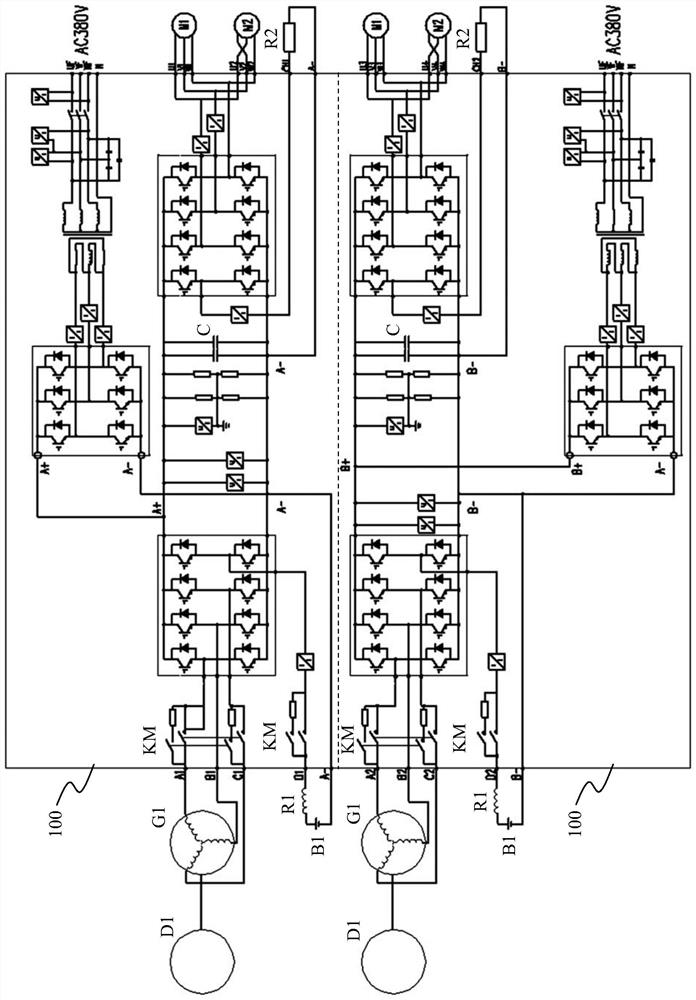

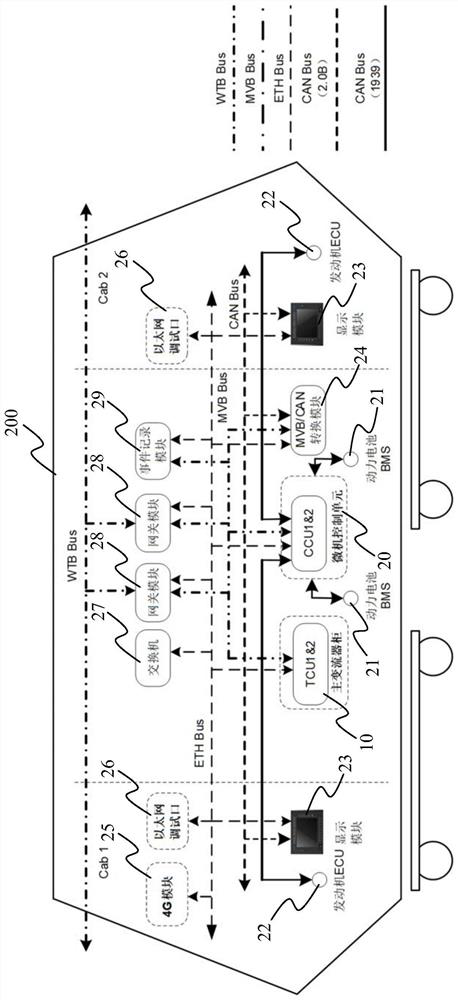

[0059] as attached figure 1 And attached figure 2As shown, an embodiment of the hybrid electric rail car electrical system based on the control method of the present invention specifically includes: one or more main and auxiliary integrated converters 100, and the main and auxiliary integrated converters 100. The number corresponds to the engine D1, generator G1, power battery B1, chopper reactor R1 and traction motor. The main and auxiliary integrated converter 100 further includes a rectification module 11, a first bridge arm 12, an intermediate DC link 13, a traction inverter module 15 connected in sequence, an auxiliary inverter module 16 connected to the intermediate DC link 13, and an auxiliary inverter module 16 connected to the intermediate DC link 13. The isolated output module 17 connected to the transformer module 16 (specifically, an isolation transformer is used). The engine D1 is connected to the generator G1 , and the generator G1 is further connected to the ...

Embodiment 2

[0085] as attached figure 1 And attached figure 2 As shown, an embodiment of the electrical control method for a hybrid rail vehicle of the present invention, the main and auxiliary integrated converter 100 includes two power sources of the engine D1 and the power battery B1, and the method specifically includes the following mode steps:

[0086] Generator power supply mode: the engine D1 drives the generator G1 to generate three-phase alternating current, which is converted into an intermediate DC power supply after controllable rectification by the rectifier module 11 to supply power for the intermediate DC link 13, and the intermediate DC power supply is the traction inverter module 15 and the auxiliary inverter The module 16 supplies power, the traction inverter module 15 outputs electric energy to the traction motor, and the auxiliary inverter module 16 outputs electric energy to the auxiliary load 30 .

[0087] Power battery power supply mode: the power battery B1 is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com