Efficient and stable novel photo-thermal water evaporation material with self-cleaning function and preparation method thereof

A self-cleaning, new type of technology, applied in general water supply conservation, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as easy loss of water vapor, difficult to clean heat, easy loss of surface, etc., to facilitate daily management, reduce Effect of heat loss and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Preparation of new photothermal and hot water evaporation materials with high efficiency, stability and self-cleaning function

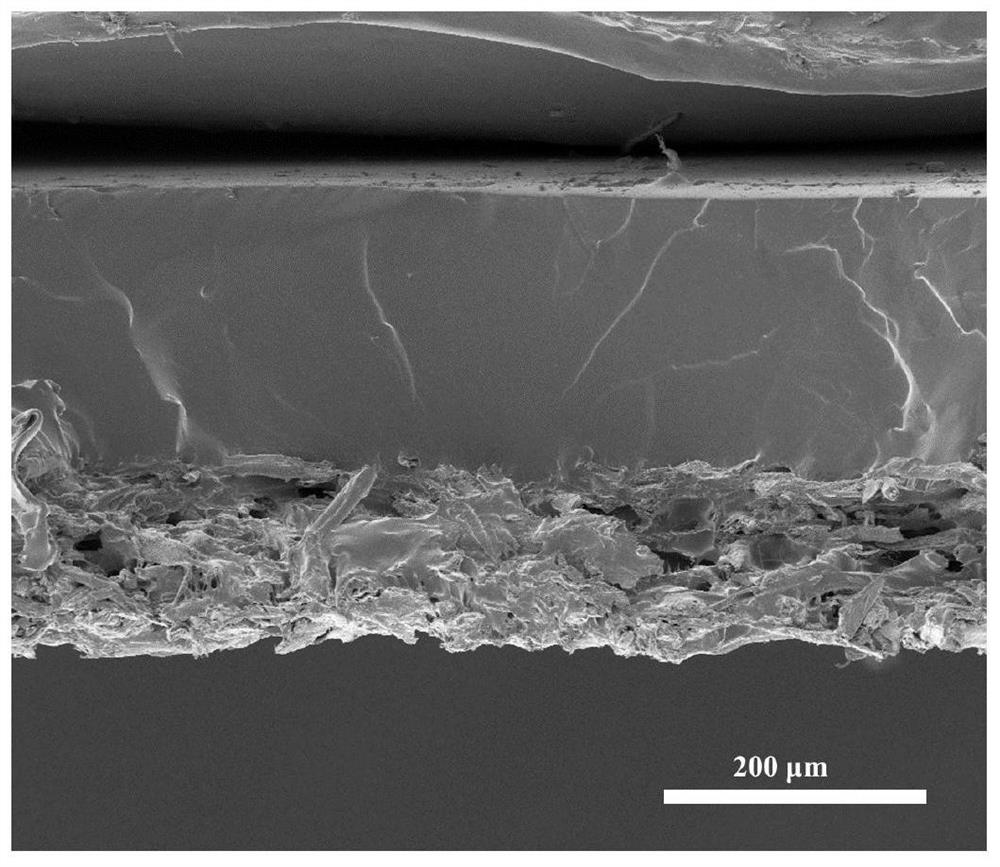

[0037] 1) Select a hydrophilic non-woven fabric with a thickness of 200 μm, cut it into a disc with a diameter of 3 cm, ultrasonicate it in ethanol at a frequency of 30 kHz for 5 minutes, then replace the ethanol with deionized water, and use the same frequency Sonicate for 5 minutes, and wash three times with repeated water changes. Take out the material, put it in an oven at 60°C for 6 hours to dry, and obtain the bottom layer of the water-absorbent material;

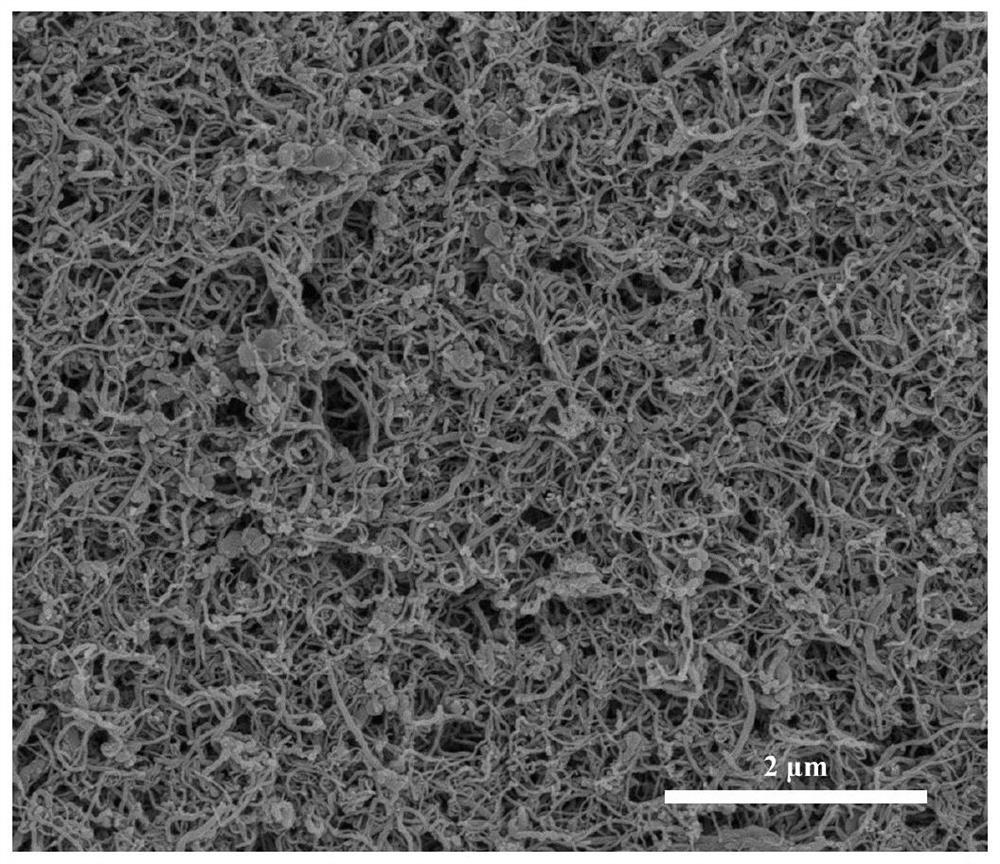

[0038] 2) Weigh 20 mg of carbon nanotube powder, disperse in 3 ml of ethanol solution, and ultrasonically disperse at a frequency of 30 kHz for 15 min to obtain a suspension;

[0039] 3) Evenly drop the suspension obtained in step (2) onto the bottom layer of the water-absorbing material obtained in step (1), and add dropwise in 4 times. After each drop, put it in an oven at 50°C ...

Embodiment 2

[0050] With embodiment 1, but the scraping film thickness is 150 μ m, adopts Figure 5 The light and hot water evaporation device shown is tested under the irradiation of twice the intensity of sunlight, and the relationship between the amount of water evaporation and the illumination time is obtained. In addition, the photothermal materials with and without the PDMS protective layer were washed with water for 7 times, and the photothermal water evaporation test was carried out after each washing.

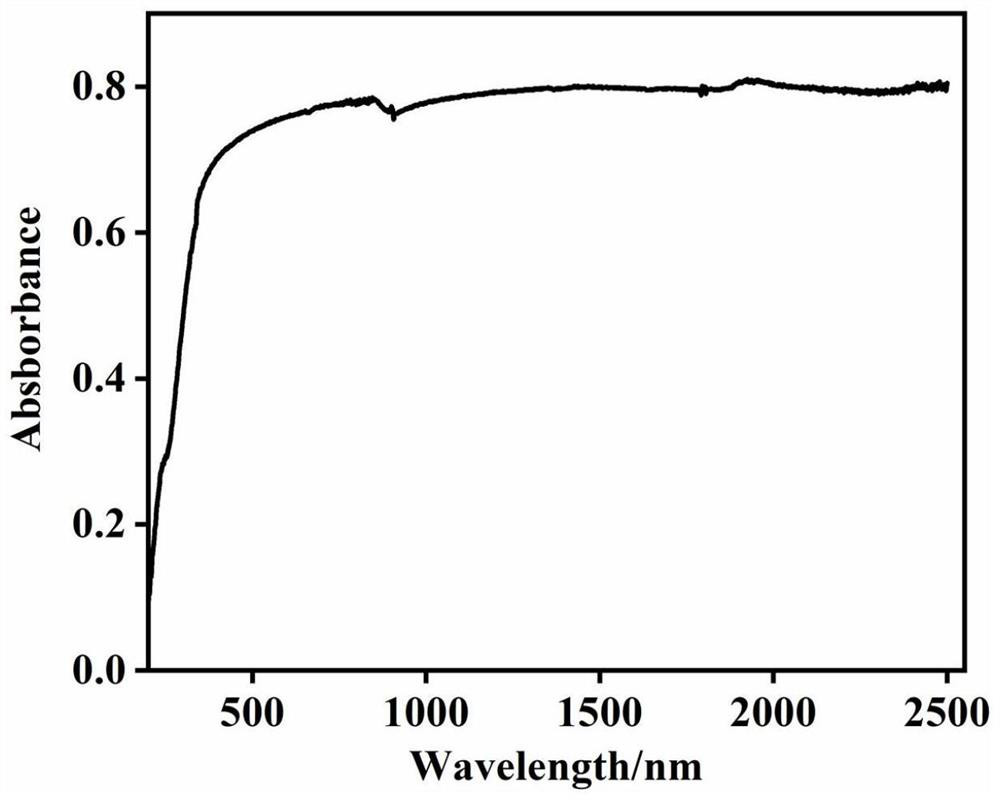

[0051] Figure 9 The relationship between evaporation rate and time of pure water, photothermal material without PDMS protective layer and photothermal material with PDMS protective layer under the irradiation of twice the intensity of sunlight. It can be seen from the comparison that with or without PDMS protective layer The water evaporation efficiency of the photothermal materials is not much different before being washed by water, which is about 4 times the evaporation efficie...

Embodiment 3

[0054] Same as Example 1, but the scraping film thickness is 250 μm. The obtained light-to-heat conversion material is used for Figure 11 The device shown is closed for fresh water collection, and fresh water collection can be carried out without affecting the light intensity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com