Low-carbon-source sewage treatment device and treatment method

A technology of sewage treatment device and sewage treatment method, which is applied in water/sewage treatment, biological treatment device, biological water/sewage treatment, etc., can solve the difficulty of treatment and disposal, the requirements of numerical control and operating conditions are relatively high, and it is impossible to take into account the denitrification at the same time. and phosphorus removal, to achieve the effect of strengthening the effect of nitrogen and phosphorus removal, reducing the impact and increasing the output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

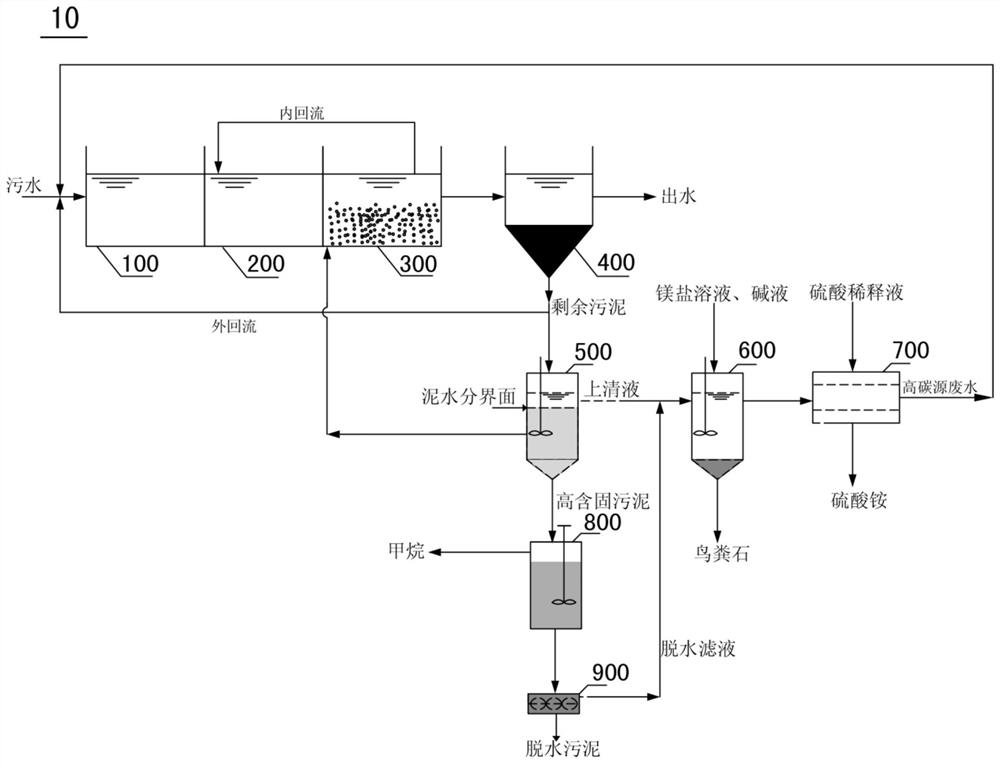

[0068] This embodiment provides a low-carbon source sewage treatment device 10 .

[0069] A low-carbon source sewage treatment device 10, including anaerobic tank 100, anoxic tank 200, aeration tank 300, secondary settling tank 400, biological selection mud-water separation tank 500, phosphorus recovery tank 600, ammonia nitrogen recovery tank 700, high content Solid anaerobic fermentation tank 800 and muddy water dehydration mechanism 900.

[0070] The anaerobic tank 100, the anoxic tank 200, the aeration tank 300, the secondary sedimentation tank 400, the biological selection mud-water separation tank 500, the phosphorus recovery tank 600 and the ammonia nitrogen recovery tank 700 are sequentially connected along the sewage flow direction. The high-solid anaerobic fermentation tank 800 is connected with the biological selection mud-water separation tank 500 . The muddy water dehydration mechanism 900 is connected with the high-solid anaerobic fermentation tank 800 .

[007...

Embodiment 2

[0080] This embodiment provides a low-carbon source influent sewage treatment method with the characteristics of sludge reduction and carbon, nitrogen and phosphorus resource recovery. The method uses the low-carbon source sewage treatment device 10 in Example 1.

[0081] A low-carbon source influent sewage treatment method with the characteristics of sludge reduction and carbon, nitrogen and phosphorus resource recovery, comprising the following steps:

[0082] Sewage treatment stage: urban sewage from low-carbon sources enters anaerobic tank 100, anoxic tank 200, aeration tank 300 and secondary sedimentation tank 400 for anaerobic treatment, anoxic treatment, aeration treatment and sedimentation treatment respectively to control anaerobic The hydraulic retention times in the tank 100, the anoxic tank 200 and the aeration tank 300 are 2 hours, 2 hours and 6 hours respectively. The sludge internal reflux ratio is 80% to 120%, and the sludge external reflux ratio is 10% to 50%...

Embodiment 3

[0089] In this example, the low-carbon source influent sewage treatment method with the characteristics of sludge reduction and carbon, nitrogen and phosphorus resource recovery in Example 2 is used to treat urban sewage to verify the effect of sludge reduction.

[0090] This embodiment sets the traditional A 2 / O process was used as the control group. In this embodiment 3, the residence time of the biological selection mud-water separation tank 500 is 5 days.

[0091] Compared with the control group, the apparent yield of sludge obtained by the sewage treatment method in Example 3 is 0.256KG-MLSS / KG-COD, and the apparent yield of sludge in the control group is 0.383KG-MLSS / KG-COD , the modified A2 / O process, it can be seen that the sludge growth rate in Example 3 was significantly lower than that of the control group, and a reduction effect of 33% was obtained.

[0092] Sludge apparent yield (Yobs) is an important index to measure the sludge reduction effect of the system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com