Method for preparing ultra-high performance concrete admixture by using concrete waste slurry

A concrete admixture and ultra-high-performance technology, which is applied in the field of concrete material preparation, can solve the problems of reduced overall strength of concrete, reduced early strength of concrete, and smaller expansion and slump of concrete mixture, so as to achieve resource utilization and fine high-end utilization, ensuring the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

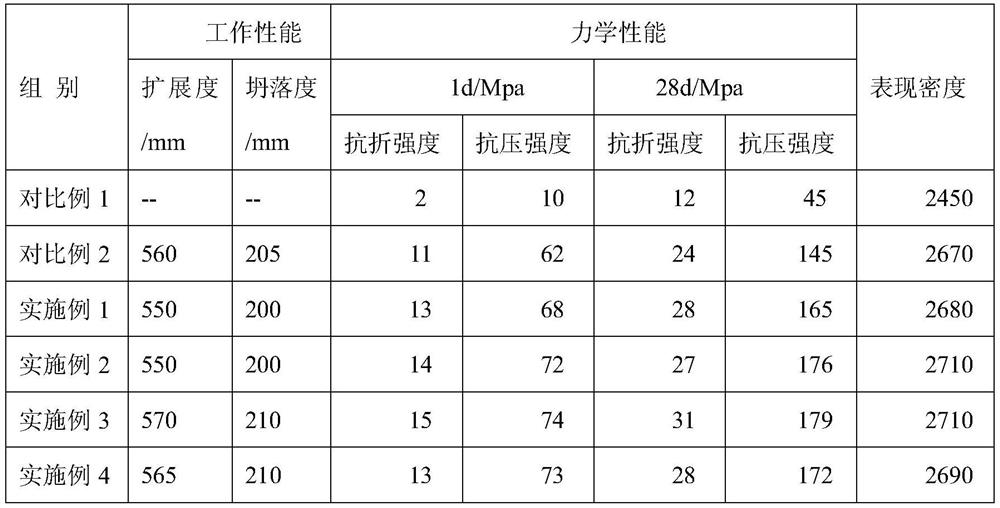

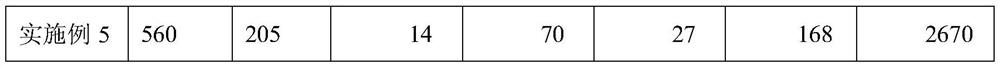

Examples

Embodiment 1

[0024] A method for preparing ultra-high performance concrete admixture by utilizing concrete waste slurry, comprising:

[0025] (1) After adding the waste concrete slurry to the surfactant, stir and ultrasonically disperse to form a suspension dispersion, then dropwise add a mixed solution of nitric acid and ferric chloride, and carry out a neutralization reaction until the solution becomes neutral; filter impurities to form a solution A;

[0026] (2) adding the filtered impurities into the second batch of nitric acid solution, without the impurities, soaking, placing in a closed container provided with a single pipeline, injecting hydrofluoric acid solution into the container through the pipeline, and continuously stirring slowly, the reaction 6h; then slowly inject sodium hydroxide solution into the airtight container through the pipeline, and continuously stir, adjust the pH of the solution to 12, filter out the particulate matter, and obtain solution B;

[0027] (3) diss...

Embodiment 2

[0037] A method for preparing ultra-high performance concrete admixture by utilizing concrete waste slurry, comprising:

[0038] (1) After adding the waste concrete slurry to the surfactant, stir and ultrasonically disperse to form a suspension dispersion, then dropwise add a mixed solution of nitric acid and ferric chloride, and carry out a neutralization reaction until the solution becomes neutral; filter impurities to form a solution A;

[0039] (2) adding the filtered impurities into the second batch of nitric acid solution, without the impurities, soaking, placing in a closed container provided with a single pipeline, injecting hydrofluoric acid solution into the container through the pipeline, and continuously stirring slowly, the reaction 8h. Then slowly inject sodium hydroxide solution into the airtight container through the pipeline, and continuously stir, adjust the pH of the solution to 14, filter out the particulate matter, and obtain solution B;

[0040] (3) dis...

Embodiment 3

[0050] A method for preparing ultra-high performance concrete admixture by utilizing concrete waste slurry, comprising:

[0051] (1) After adding the waste concrete slurry to the surfactant, stir and ultrasonically disperse to form a suspension dispersion, then dropwise add a mixed solution of nitric acid and ferric chloride, and carry out a neutralization reaction until the solution becomes neutral; filter impurities to form a solution A;

[0052] (2) adding the filtered impurities into the second batch of nitric acid solution, without the impurities, soaking, placing in a closed container provided with a single pipeline, injecting hydrofluoric acid solution into the container through the pipeline, and continuously stirring slowly, the reaction 7h. Then slowly inject sodium hydroxide solution into the airtight container through the pipeline, and continuously stir, adjust the pH of the solution to 13, filter out the particulate matter, and obtain solution B;

[0053] (3) dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com