Water-based metal cutting fluid and preparation method thereof

A technology of base metal and cutting fluid, applied in the field of water-based metal cutting fluid and its preparation, can solve the problems of small filter mesh, inability to discharge liquid, low filtration efficiency, etc., to ensure the filtration effect, improve the collection efficiency, and speed up the filtration. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] A method for preparing a water-based metal cutting fluid, the preparation method is applicable to the above-mentioned water-based metal cutting fluid; the steps of the method are as follows:

[0061] S1: Put diethylene glycol borate, polyethylene glycol, sodium benzoate, trisodium phosphate, simethicone oil, sulfurized calcium alkylphenate into the mixer according to the ratio of deionized water, and heat up to 75-85°C. Stir for 8-12 minutes;

[0062] S2: first lower the temperature in the mixer to 45-50°C, then put triethanolamine, vegetable oil, polysilicon ester, methyl butynol and dispersant into the mixer in proportion, and stir for 30-35 minutes;

[0063] S3: Take out the mixture in the mixer and put it into the filter, filter the material with a 200-mesh filter, which is the cutting fluid product.

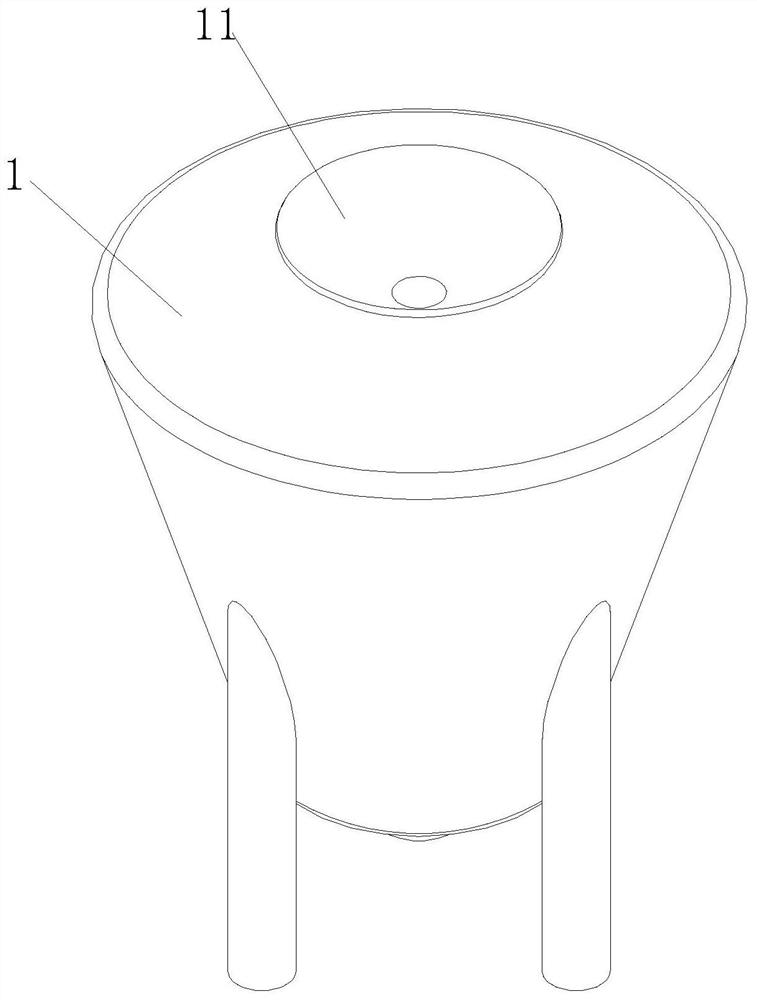

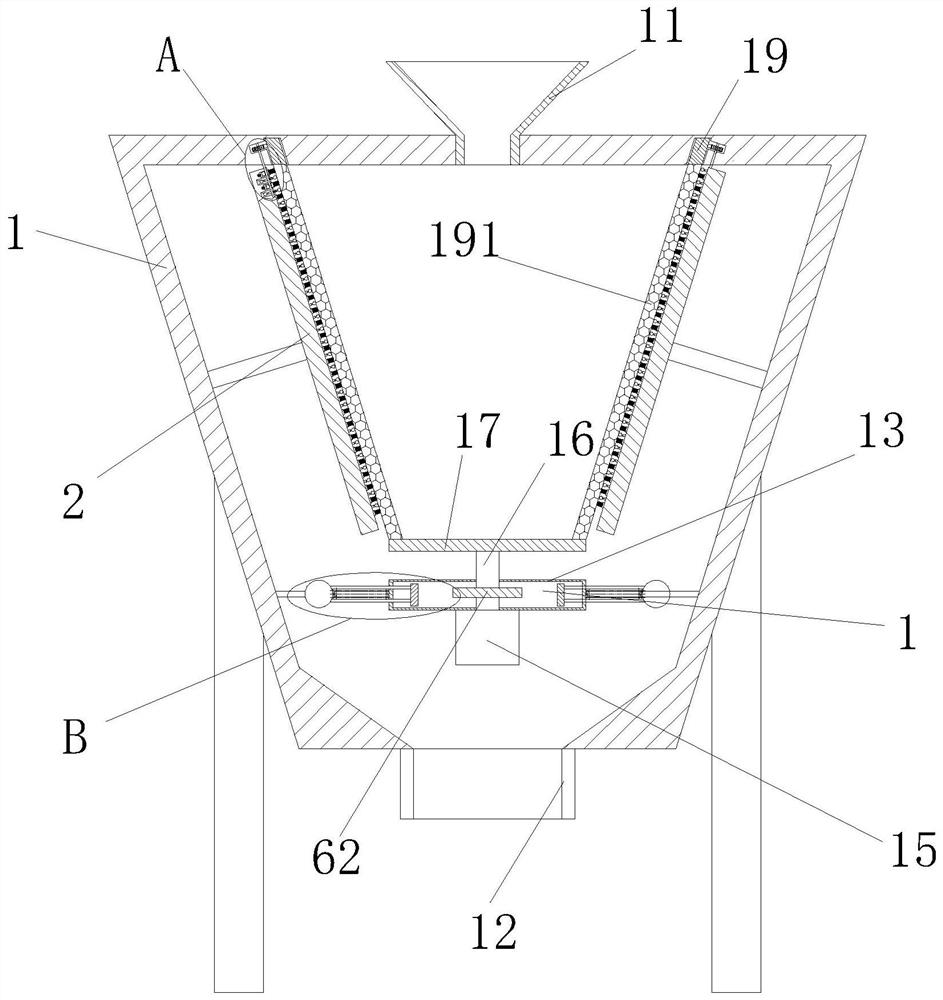

[0064] As an embodiment of the present invention, the filter machine described in S3 includes a filter bucket 1; The bottom end is provided with a discharge port 12...

Embodiment approach

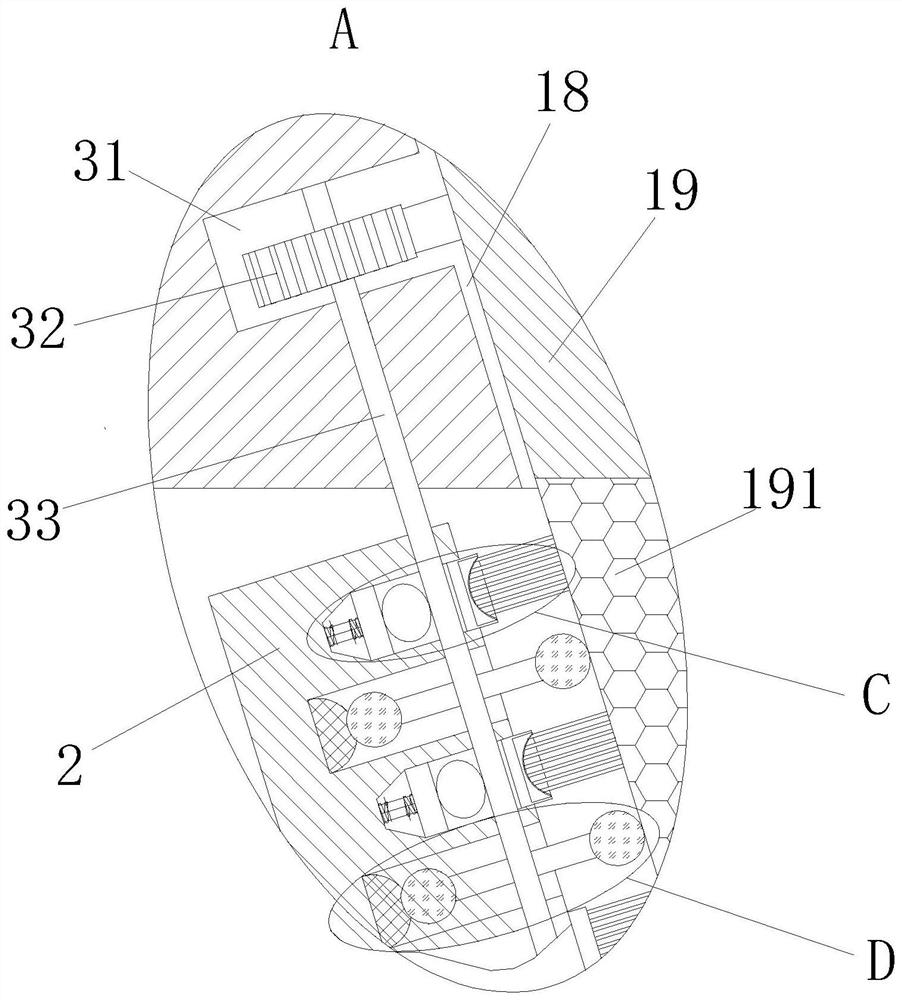

[0066] As an embodiment of the present invention, a group of second grooves 3 are provided on the side wall of the cleaning plate 2 close to the filter screen 191, and the second grooves 3 are located between the first grooves 21; the annular grooves A pair of symmetrically distributed third grooves 31 are provided on the side wall of 18; a second rotating shaft 33 is rotatably connected to the side wall of the third groove 31, and the second rotating shaft 33 runs through the first cleaning plate 2. The groove 21 and the second groove 3; the push block 22 is provided with a through groove 34, and the axis of the second rotating shaft 33 passing through the first groove 21 is located in the through groove 34; the second rotating shaft 33 is located in the through groove 34; A pair of symmetrically distributed rotating rods 35 are fixedly connected to the shaft of the second groove 3, and a collision ball 36 is fixedly connected to the end of the rotating rod 35; the collision b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com