Drafting device for spinning

A drafting device and drafting technology, applied in drafting equipment, textiles, papermaking, spinning machines, etc., can solve the problems of non-concentration of textile threads and inability to adjust the distance of drafting, so as to prevent knotting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

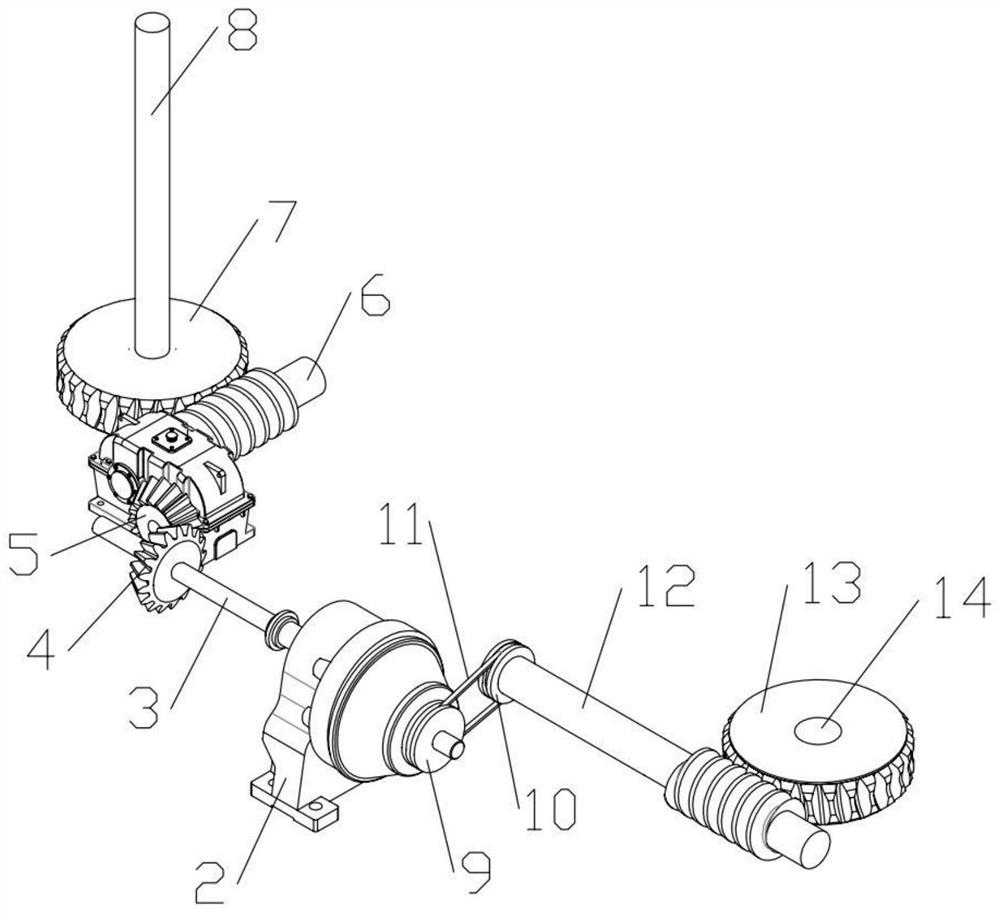

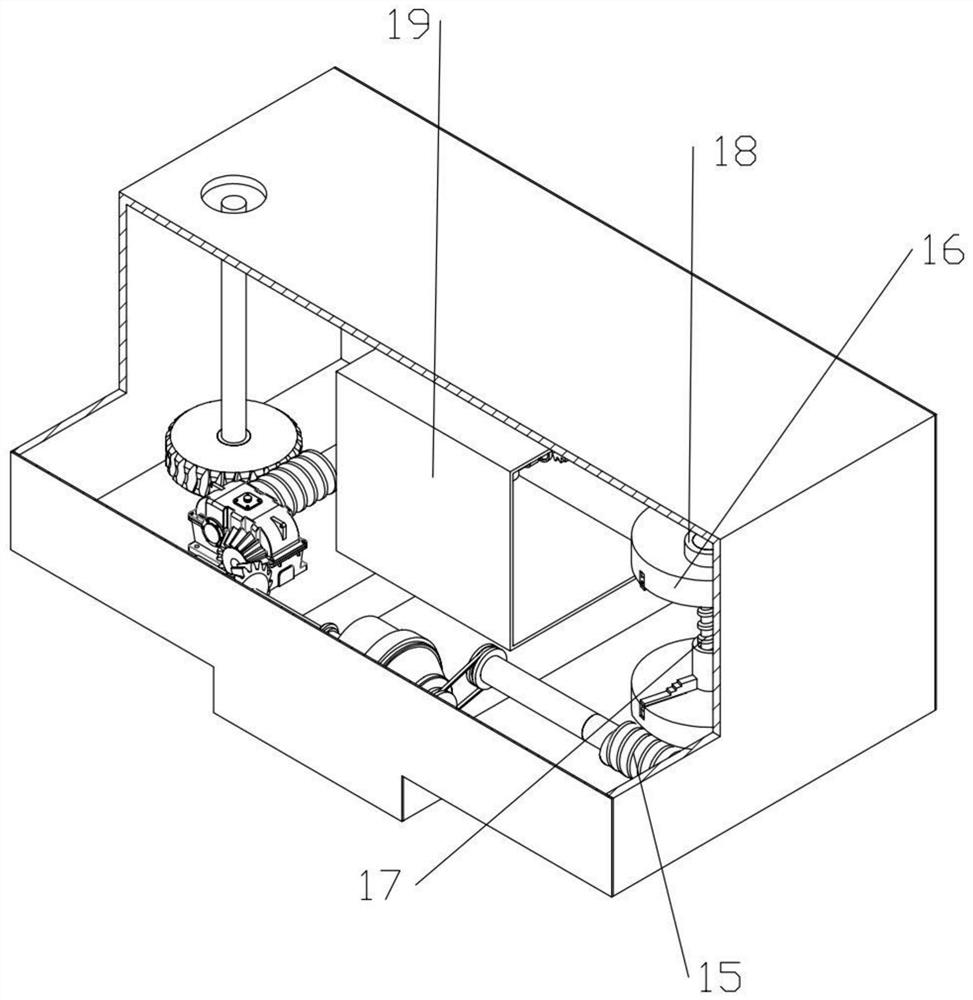

[0034] Combine below Figure 1-18 In order to solve the above-mentioned technical problems, the present invention relates to the technical field of textile machinery, more specifically a drafting device for textiles. The textile thread roll is put in through the groove on the body 1, and the side cover of the body 1 is opened. Put the wire roller into the device, the main shaft of the rolling motor 2 is connected with the reel-3 through a coupling to drive the rotation of the reel-3, and the reel-3 is connected with the helical gear-4 key to make the helical gear-4 rotate accordingly. The first helical gear 4 meshes with the second helical gear 5 to drive the second helical gear 5 to rotate in the opposite direction. The second helical gear 5 is keyed to the input shaft of the reducer to make the reducer run. The shaft device can make the rolling worm one 6 reversely rotate thereupon, and the rolling worm one 6 is meshed with the scrolling turbine one 7 and then drives the rev...

specific Embodiment approach 2

[0035] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain Embodiment 1, the main shaft of the clamping motor 15-2 is connected with the clamping worm 15-3 through a coupling, so that the rotation of the clamping motor 15-2 can drive the clamping worm The rotation of 15-3, the locking worm 15-3 meshes with the locking turbine 15-4 to further drive the rotation of the locking turbine 15-4, and the locking turbine 15-4 is fixedly connected with the locking shaft 15-5 to drive The rotation of the locking shaft 15-5, the locking shaft 15-5 is fixedly connected with the slide plate 15-6 and then drives the rotation of the slide plate 15-6, and the inclined chute is processed on the slide plate 15-6, when the slide plate 15-6 rotates At the same time, since each group of inclined chute is slidingly connected with the slide bar 15-7, under the rotation of the inclined chute, the movement of the slide bar 15-7 is driven, and the slide bar 15-7 can...

specific Embodiment approach 3

[0036] Combine below Figure 1-18 This embodiment will be described. This embodiment will further explain Embodiment 1. The adjustment plate 18-1 and the upper clamping device 16 are hinged spherically, so that the adjustment plate 18-1 can drive the upper clamping device 16 to move up and down. The positioning device 16 can also be rotated to prevent the rotation of the upper clamping device 16 from affecting the normal movement of the adjusting device 18. When the textile thread is processed, the floating hair on the textile thread will be blown off by a fan. For the sake of environmental protection, energy can be reused The idea is to blow the floating hair with the wind of the fan, and then connect the wind in the device to the air duct with the switch through the upper and lower power slots. When the switch on the air duct of the upper power slot is turned on, the wind blows the wave The blade 18-8, because the force-bearing area of the wave-shaped blade 18-8 generates ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com