High-breathability protective garment and production method

A production method and technology of protective clothing, applied in the direction of biochemical fiber treatment, liquid-repellent fiber, fiber type, etc., can solve the inconvenient glue treatment of fabrics of different thicknesses, poor air permeability of protective clothing, and difficulty in spraying glue on fabrics Uniformity and other problems to achieve the effect of improving waterproof effect, improving protective effect, and improving antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

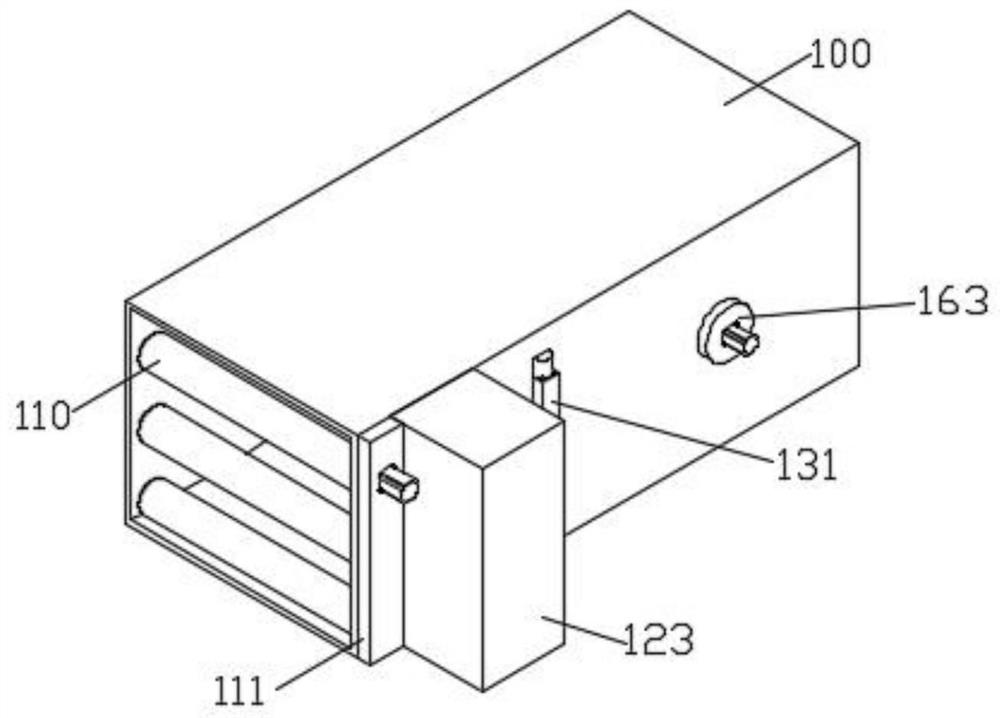

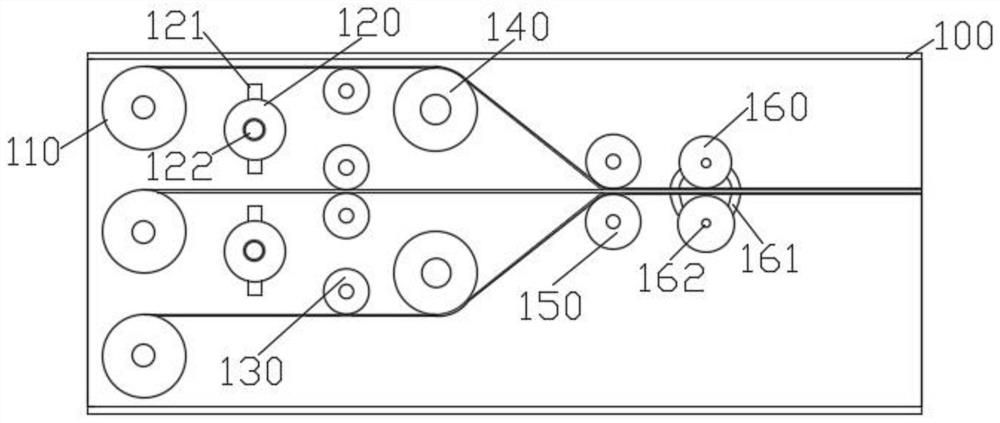

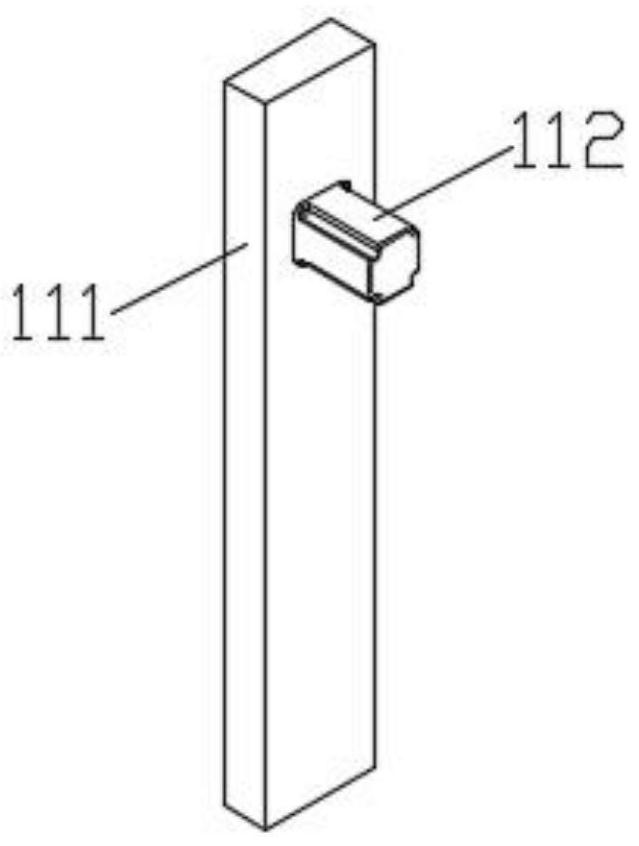

Image

Examples

Embodiment 1

[0039] A high-breathability protective clothing, the protective clothing is composed of an inner fabric, a middle fabric, and an outer fabric;

[0040] Wherein, the highly breathable protective clothing is prepared through the following steps:

[0041] Step 1: Use graphene oxide solution to spray one side of the inner fabric, and dry it below 55°C to obtain a graphene oxide modified fabric. Use a reducing agent to reduce the graphene oxide modified fabric, dry it, and make it protective fabrics;

[0042] Step 2: Spread the linseed paint evenly on the surface of the middle layer fabric, and then put it in the oven to bake for 2.5 hours. The temperature in the oven is kept at 130°C. Put the middle layer fabric into the waterproof agent and continue to circulate it, while heating to 170°C , lasted for 2.5h to obtain a waterproof fabric, put the waterproof fabric into the antibacterial sol and continuously pull it in a circular manner, while heating to 180°C for 2h to obtain an a...

Embodiment 2

[0051] The highly breathable protective clothing is prepared through the following steps:

[0052] Step 1 is identical with embodiment 1;

[0053] Step 2: Spread the linseed paint evenly on the surface of the middle layer fabric, and then put it in the oven to bake for 3 hours. The temperature in the oven is kept at 160°C. Put the middle layer fabric into the waterproof agent and continue to circulate it. At the same time, heat it to 190°C. Continue for 3.5 hours to obtain a waterproof fabric. Put the waterproof fabric into the antibacterial sol and continue to pull it circularly. At the same time, heat it to 200°C for 3 hours to obtain an antibacterial and waterproof fabric;

[0054] Step 3: 20 parts by weight of fluorocarbon emulsion, 2 parts by weight of glycerol phosphate, 4 parts by weight of trifluoropropylmethylcyclotrisiloxane, 5 parts by weight of titanate coupling agent, 24 parts by weight of ethyl dimercaptoacetate Glycol ester, 24 parts by weight of lauryl alcohol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com