Closed air cooling tower process and system based on micro-interface hydrophilic filler

A cooling tower and interface technology, applied in the field of cooling towers, can solve the problems of high operating cost and energy consumption, achieve high popularization, improve mass transfer and heat transfer efficiency, and overcome high water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

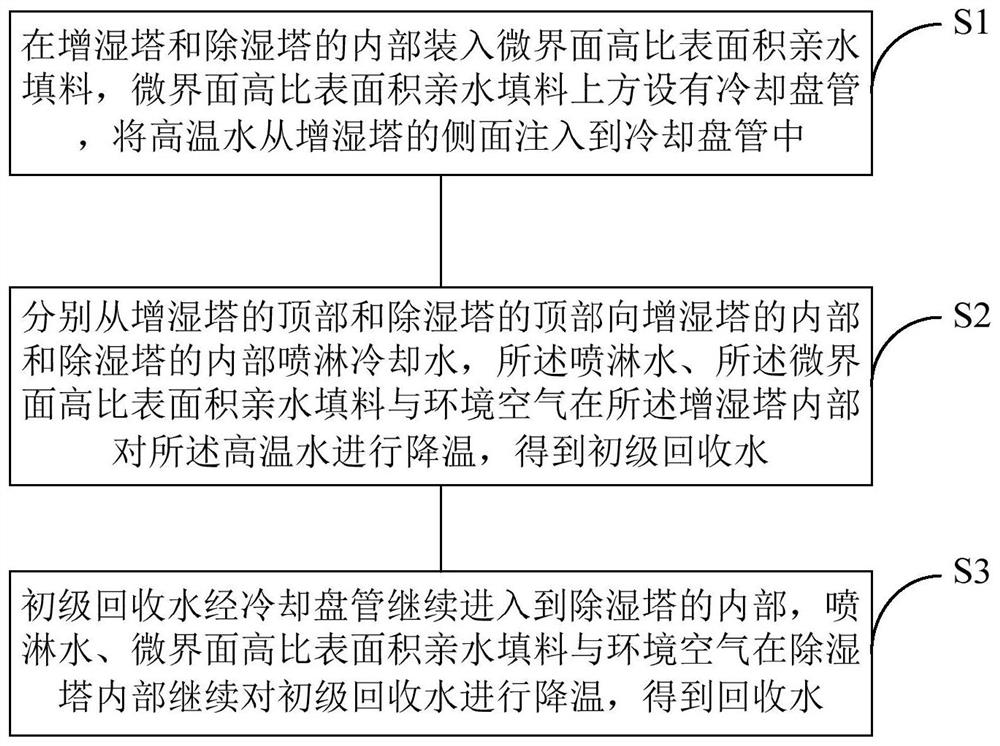

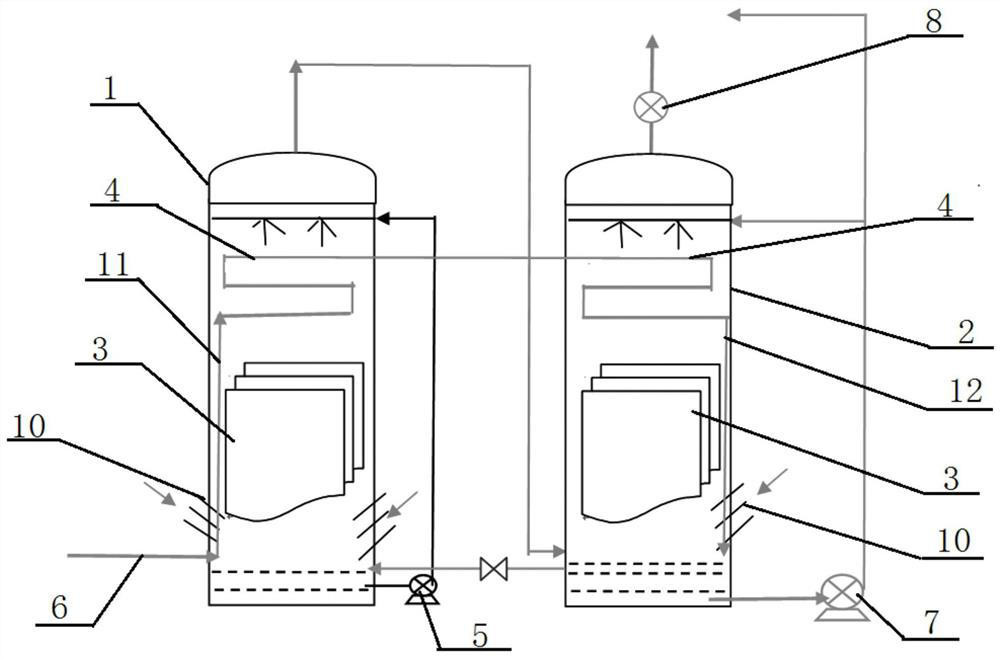

[0027] see figure 1 , a schematic flow diagram of a closed-type air cooling tower process based on micro-interface hydrophilic fillers provided by an embodiment of the present application. For the convenience of description, only the parts related to this embodiment are shown, and the details are as follows:

[0028] In one embodiment, the first aspect of the present application provides a closed-type air cooling tower process based on micro-interface hydrophilic fillers for cooling high-temperature water, including the following steps:

[0029] S1. Install micro-interface high specific surface area hydrophilic packing inside the humidification tower and dehumidification tower, and install a cooling coil above the micro-interface high specific surface area hydrophilic packing, and inject high-temperature water from the side of the humidification tower into the cooling plate tube.

[0030] Specifically, both the humidification tower and the dehumidification tower are made of c...

Embodiment 2

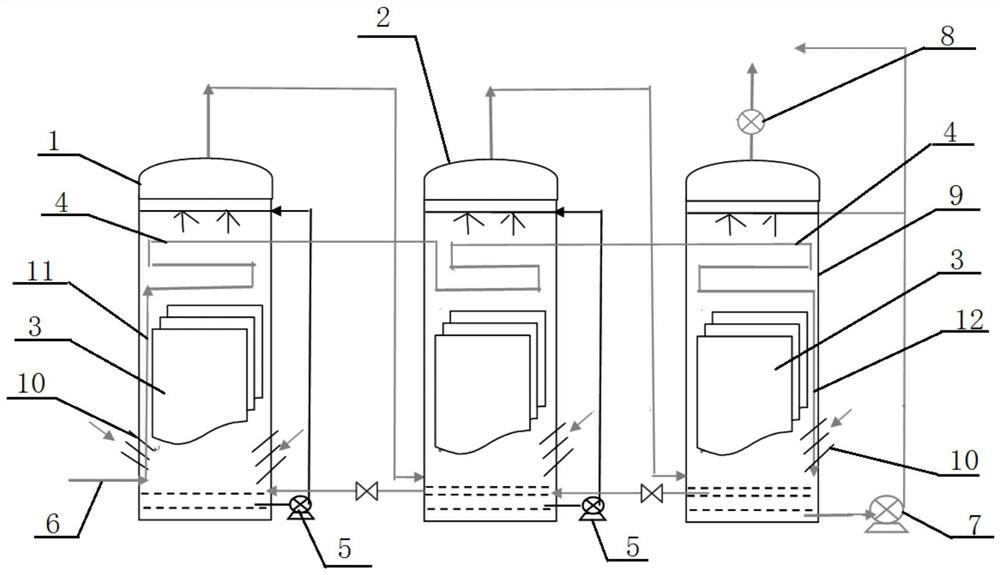

[0040] The rest are the same as in Example 1, the difference is that there are at least two dehumidification towers, the primary recovered water is cooled by at least two dehumidification towers to obtain recovered water, the cooling coils in each tower are connected, and the outlet pipes are installed in Inside the last stage of dehumidification tower, the primary recycled water is cooled step by step through each dehumidification tower until the temperature of the recycled water drops to 20-22°C, and then pumped into the cooling water storage tank for recycling. The dehumidified environment inside the dehumidification tower The air is discharged into the atmosphere through the induced draft fan at the top of the last stage dehumidification tower.

[0041] The temperature of the high temperature water to be cooled is 50-60°C, and the flow rate is 210m 3 / h, in order to prevent fouling, the linear velocity of high-temperature water in the cooling coil is designed to be 0.8-1.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com