A textile fiber strength detection device

A technology for textile fiber and strength detection, applied in the direction of measurement device, strength characteristics, and the use of stable tension/pressure to test the strength of materials, etc. Ensure uniformity and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

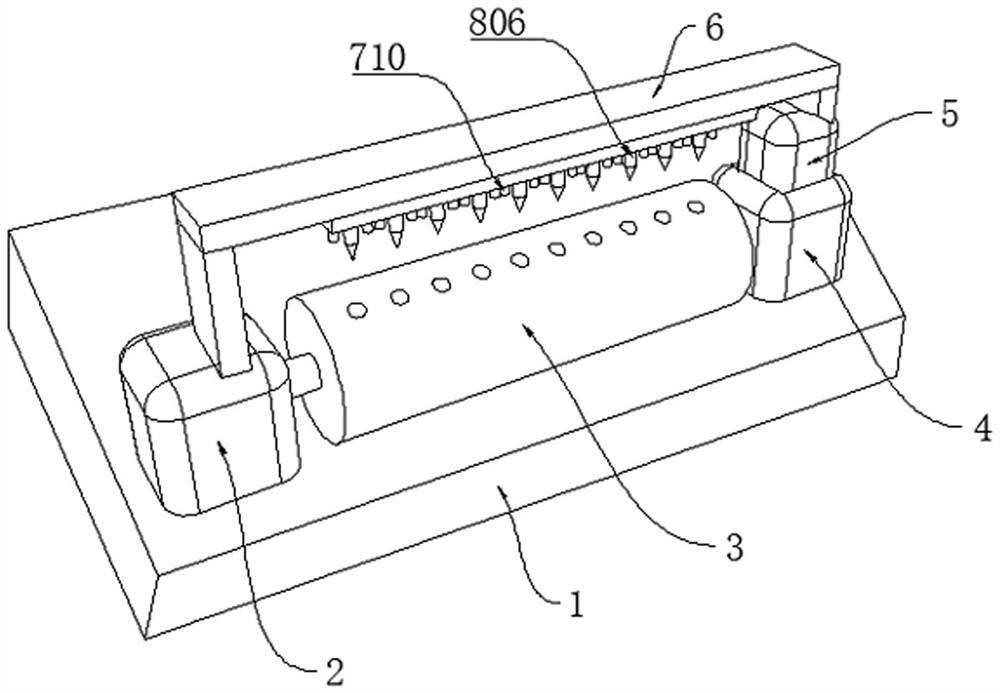

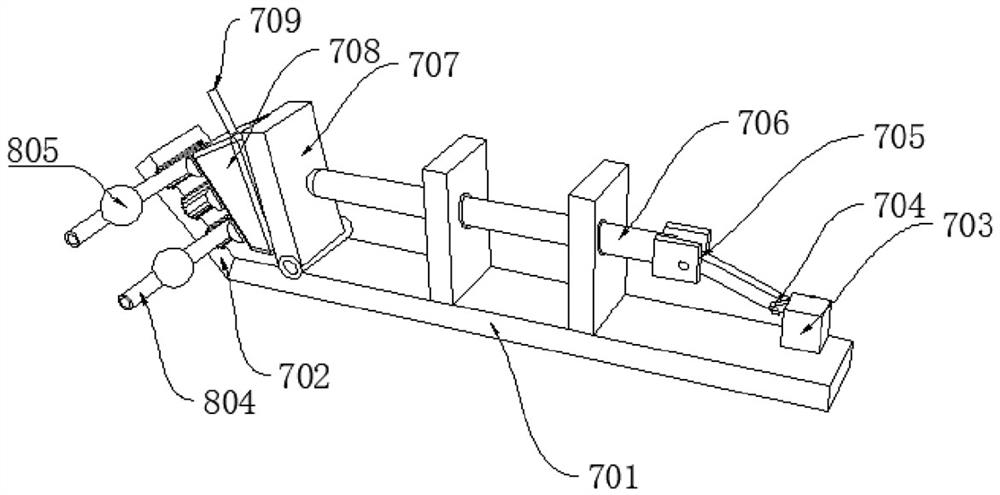

[0033] Example 1: See Figure 1-2 , comprising a workbench 1, the workbench 1 is provided with an electromagnetic tensioner 2, one side of the electromagnetic tensioner 2 is provided with a fixed frame 3, and the fixed frame 3 is provided with a water-immersed property for detecting fibers and in a humid environment. The detection device for the structural strength below is provided with a mounting frame 4 on the side away from the connection side between the fixed frame 3 and the electromagnetic tensioner 2. The fixed frame 3 refers to the fixed frame in the invention patent with the publication number CN112198048B mentioned in the background technology , the detection device is the detection component mentioned in the patent. The implementation of the detection device is to control the magnitude of the current flowing through the electromagnetic seat tube with a rheostat by setting an electromagnetic tensioner, and change its magnetic field strength, so that the magnetic attr...

Embodiment 2

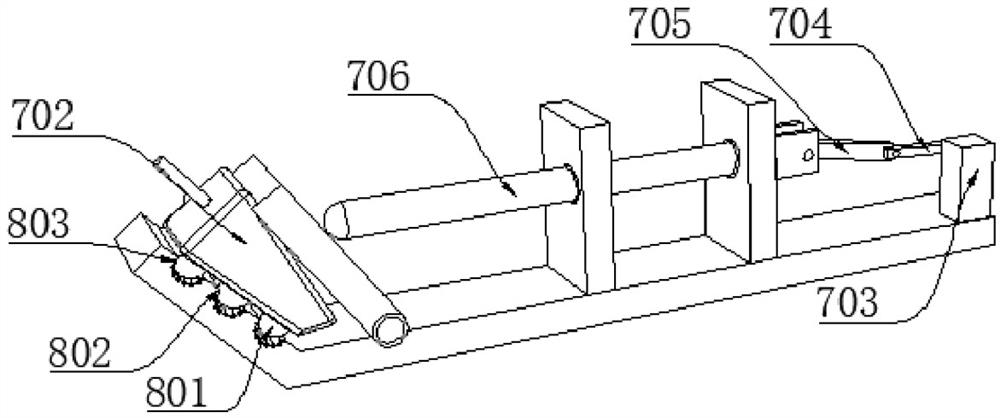

[0045] Embodiment 2: It should be noted that this invention adopts a preferred solution to realize the left and right sliding of the atomizing nozzle 806, which is convenient to ensure the uniformity of water spraying. As shown in 6, a pusher assembly 10 is provided on the pressure-fitting ball 805 to push The assembly 10 includes a push plate 1001 arranged on one side of the pressure-fitting ball 805, a rack bar 1002 is fixedly installed on one side of the push plate 1001, a gear is provided on the meshing side of the rack bar 1002, and a toggle lever 1003 is provided on the gear. A slider 1004 is connected to the end of the toggle lever 1003 , and a chute 1005 is connected to the lower side of the slider 1004 .

[0046] Through the expansion of the pressure-fitting ball 805, the push plate 1001 is squeezed, causing the rack bar 1002 to slide, thereby causing the gear to rotate, thereby causing the toggle rod 1003 to rotate in a circle, prompting the push plate 1001 to push th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com