Mixed gas calorific value metering method

A technology of mixing gas and metering method, applied in the direction of thermal development of materials, etc., can solve the problems of complicated calculation, high equipment investment cost, not meeting the requirements of cost reduction and efficiency increase, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

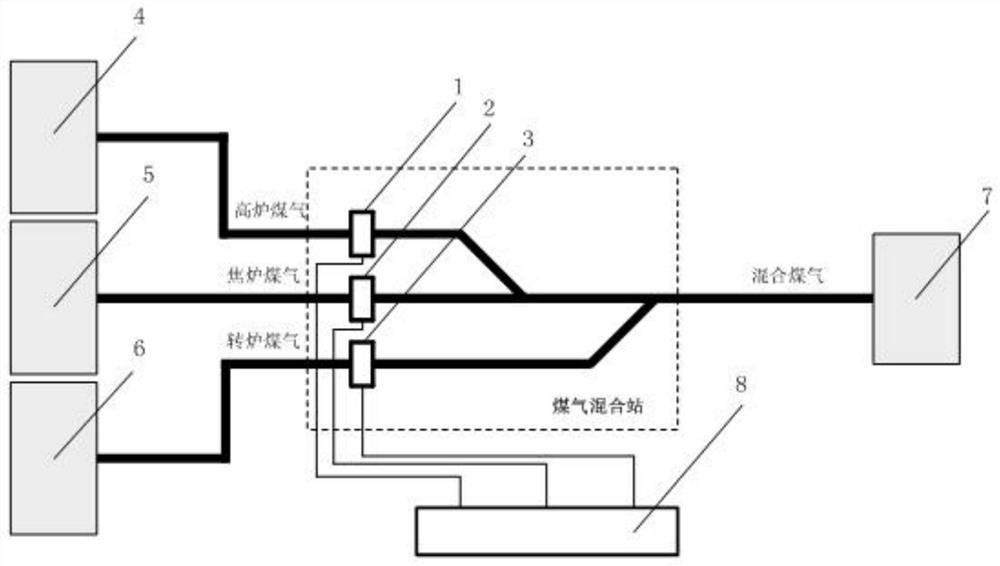

[0026] Such as figure 1 As shown, a method for measuring the calorific value of mixed gas, its main structure includes a blast furnace gas flow meter 1, a coke oven gas flow meter 2, a converter gas flow meter 3, a blast furnace gas cabinet 4, a coke oven gas cabinet 5, a converter Gas cabinet 6 and user 7, PLC or DCS system 8; the blast furnace gas flow meter 1 is a meter installed on the blast furnace gas pipeline before gas mixing; the coke oven gas flow meter 2 It is a measuring instrument installed on the coke oven gas pipeline before gas mixing for measuring the coke oven gas flow rate; the converter gas flow measuring instrument 3 is a measuring instrument installed on the converter gas pipeline before gas mixing for measuring the converter gas flow rate; The blast furnace gas flow meter 1 , the coke oven gas flow meter 2 and the converter gas flow meter 3 all adopt flow temperature and pressure compensation, and the signals are respectively connected to the PLC or DCS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com