Electronic component X-ray inspection defect automatic identification method

An electronic component, automatic recognition technology, applied in neural learning methods, character and pattern recognition, instruments, etc., can solve the problem of few component chip image detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further explain the technical means and functions adopted by the present invention to achieve the intended purpose, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

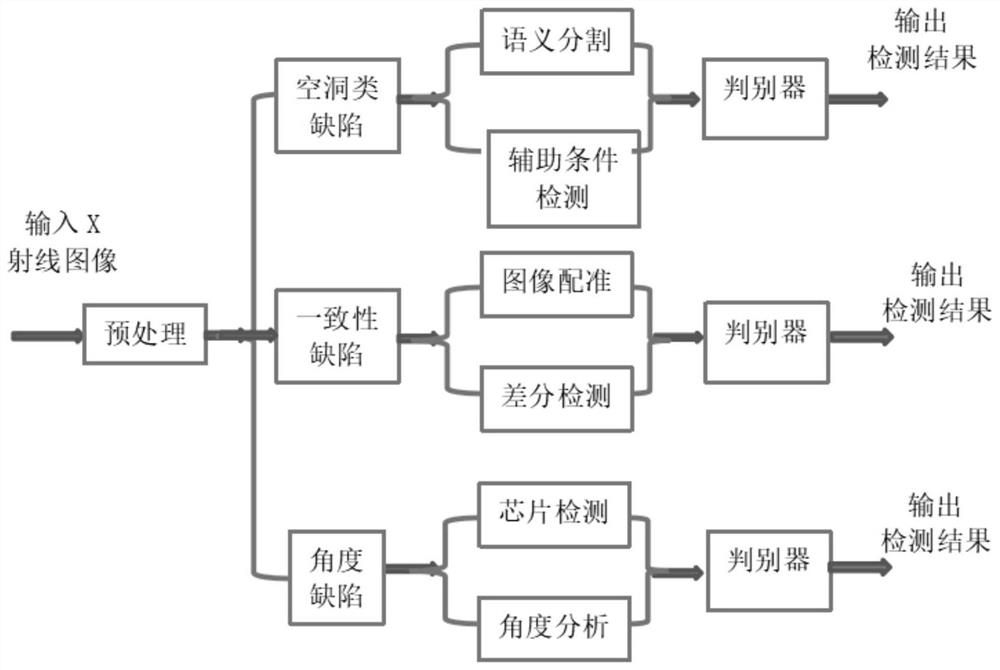

[0047] In an embodiment of the present invention, a method for automatic identification of defects in X-ray inspection of electronic components, such as figure 1 shown. The flow of the automatic detection algorithm for X-ray defects of electronic components is as follows:

[0048] Step 1: Perform preprocessing such as denoising and enhancement on the X-ray image;

[0049] Preprocessing is the primary link in various image analysis and recognition. Due to the particularity of the imaging principle, the main problem faced in the analysis and recognition of X-ray images is low contrast, so the pre-processing link in the early stage is mainly based on contrast enhancement. According to the typical characteristics of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com