Novel fluorescent label material

A fluorescent label, a new type of technology, applied in the field of label materials, can solve the problems of difficult fluorescent sensing of thin films, high storage requirements, short service life, etc., and achieve the effect of simple process, low storage requirements and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

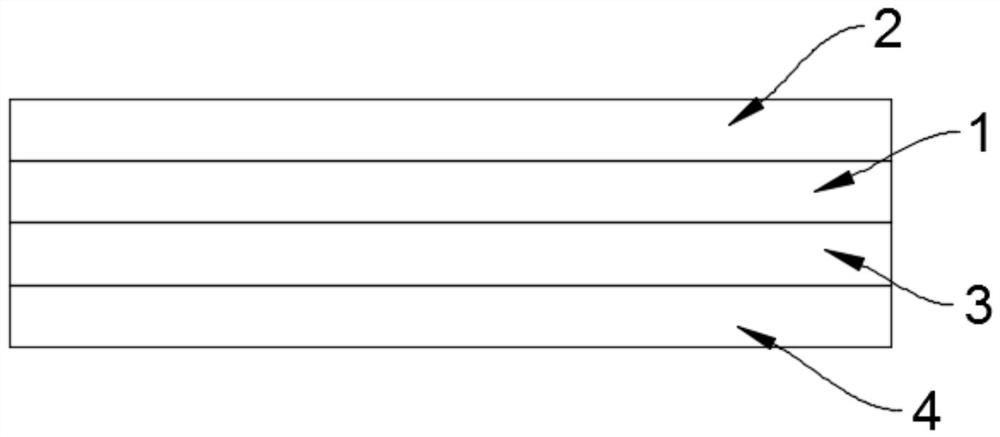

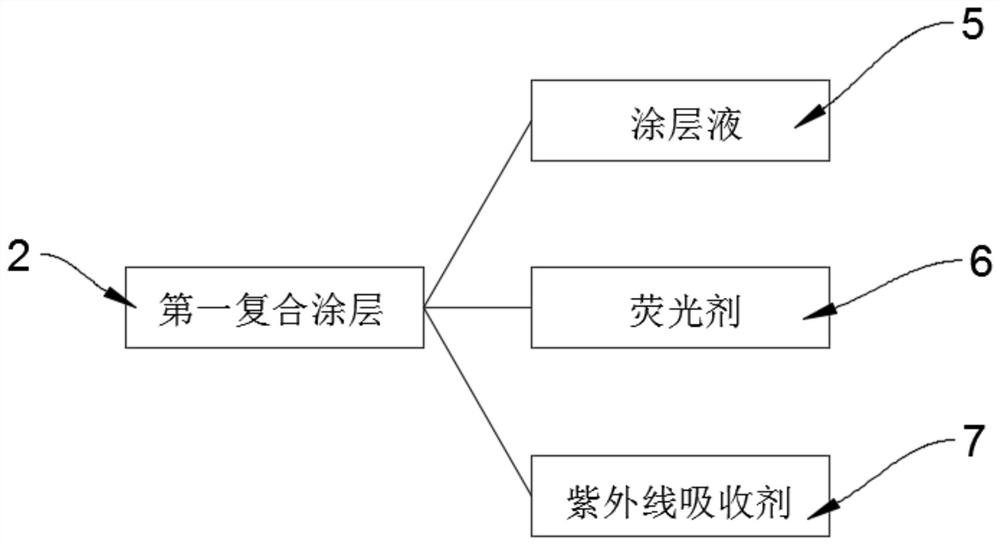

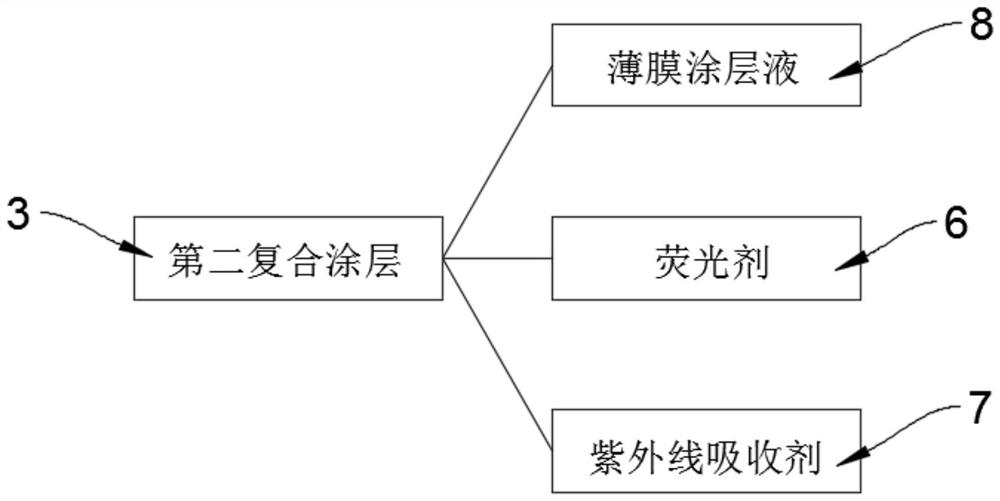

[0030]Embodiment 1. When preparing the first composite coating 2, take 5‰ of fluorescent agent 6 and 1‰ of ultraviolet absorber 7 according to the weight ratio, and other substances are coating liquid 5, and mix them at room temperature. Inject down into the inside of the external mixer and stir at a constant speed. During the stirring, observe the mixing of the coating liquid 5, the ultraviolet absorber 7 and the fluorescent agent 6, and stir until no powder particles can be seen in the mixed solution. When the first composite coating 2 and the second composite coating 3 are being prepared, take 5‰ of fluorescent agent 6, 1‰ of ultraviolet absorber 7, and others as film coating solution 8, and coat the film with The layer liquid 8, the ultraviolet absorber 7, and the fluorescent agent 6 are poured into the interior of the external mixer and stirred at a constant speed. When stirring, the stirring state is observed so that there is no different-colored powder particles in the m...

Embodiment 2

[0037] Embodiment 2, when preparing the first composite coating 2, get 8‰ of fluorescent agent 6 and 3‰ of ultraviolet absorber 7 according to the weight ratio, and other substances are coating liquid 5, mix them, and mix them at normal temperature Inject down into the inside of the external mixer and stir at a constant speed. During the stirring, observe the mixing of the coating liquid 5, the ultraviolet absorber 7 and the fluorescent agent 6, and stir until no powder particles can be seen in the mixed solution. When the first composite coating 2 and the second composite coating 3 are prepared, take 9‰ of fluorescent agent 6, 4‰ of ultraviolet absorber 7, and others as film coating liquid 8, and coat the film with The layer liquid 8, the ultraviolet absorber 7, and the fluorescent agent 6 are poured into the interior of the external mixer and stirred at a constant speed. When stirring, the stirring state is observed so that there is no different-colored powder particles in th...

Embodiment 3

[0044] Embodiment 3. When preparing the first composite coating 2, according to the weight ratio, take 6‰ of fluorescent agent 6 and 2‰ of ultraviolet absorber 7, and other substances are coating liquid 5, and mix them at room temperature. Inject down into the inside of the external mixer and stir at a constant speed. During the stirring, observe the mixing of the coating liquid 5, the ultraviolet absorber 7 and the fluorescent agent 6, and stir until no powder particles can be seen in the mixed solution. When the first composite coating 2 and the second composite coating 3 are prepared, take 79‰ of fluorescent agent 6, 3‰ of ultraviolet absorber 7, and others as film coating liquid 8, and coat the film with The layer liquid 8, the ultraviolet absorber 7, and the fluorescent agent 6 are poured into the interior of the external mixer and stirred at a constant speed. When stirring, the stirring state is observed so that there is no different-colored powder particles in the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com