Waste gas purification process for lead-acid storage battery recovery

A lead-acid battery and exhaust gas purification technology, which is applied in battery recycling, recycling technology, gas treatment, etc., can solve the problems of ineffective removal of acid gas and environmental pollution, and achieve the effect of ensuring the effect of filtration and deacidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

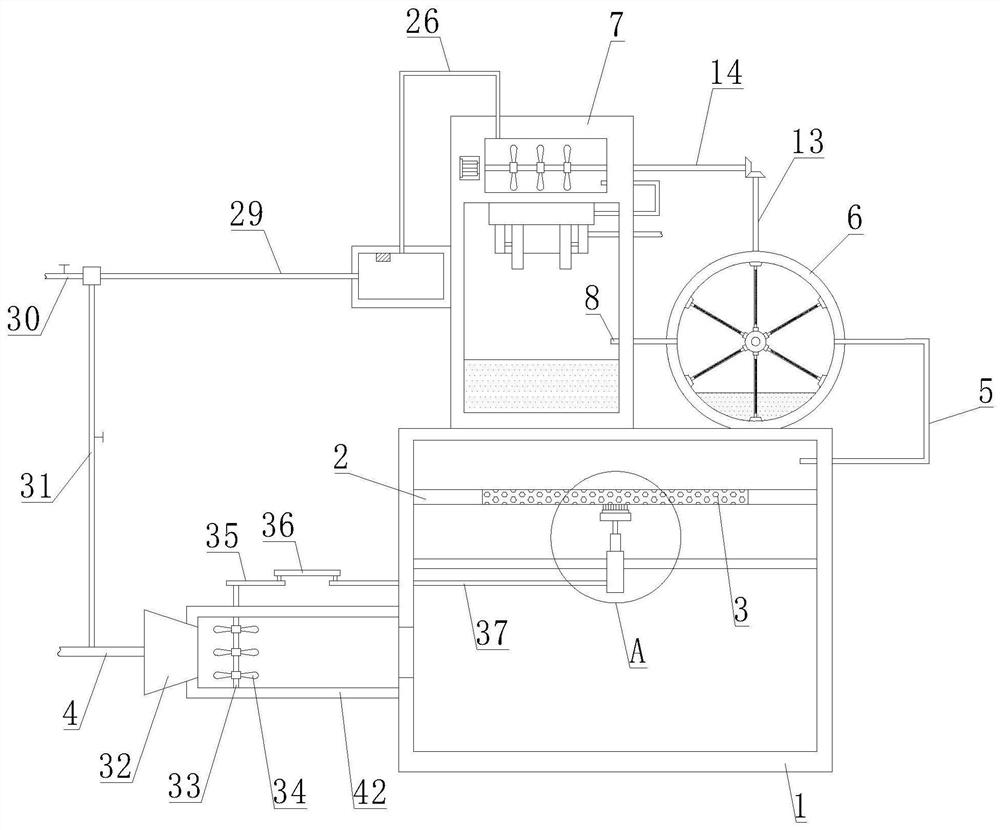

[0044] A kind of exhaust gas purification process for recycling lead-acid batteries proposed by the present invention, the exhaust gas purification process comprises the following steps:

[0045] S1. Dust filtration treatment: collect the exhaust gas generated during the recycling process of lead-acid batteries, the exhaust gas input pipe 4 leads the exhaust gas into the dust removal box 1, and the metal dust filter net 3 performs dust filtration treatment on the exhaust gas, and the filtered lead-containing dust falls into the dust removal box 1 bottom inner wall;

[0046] During the dust filtering process, the trapezoidal exhaust box 32 sprays exhaust gas to the rotating blade 34 through the flat blower port, and the rotating blade 34 drives the movable shaft 33 to rotate due to the wind force, and the pull rod 35 pulls the movable rod 37 through the rotating rod 36 to perform lateral reciprocating motion. The sliding block 38 reciprocates laterally along the guide rod 39 du...

Embodiment 2

[0057] Such as Figure 8 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the support mechanism 40 includes a fixed column 4001, an insertion rod 4002, a spring 4003, a limit slider 4004 and a limit chute 4005; the fixed column 4001 is vertically arranged on On the sliding block 38, the vertical opening is provided with an upward slot in the fixed column 4001, and the insertion rod 4002 is connected with the cleaning brush 41 and inserted downward in the fixed column 4001; The bottom of the rod 4002 is connected, the spring 4003 is in a compressed state and exerts an upward thrust on the insertion rod 4002, and the insertion rod 4002 exerts an upward thrust on the cleaning brush 41, and the cleaning brush 41 presses the metal dust filter 3 upwards, which is helpful for automatic cleaning. The particles blocked in the filter holes are brushed down, the side wall of the insertion rod 4002 is equipped with a limit slide 4004, and the limit slide 4005 i...

Embodiment 3

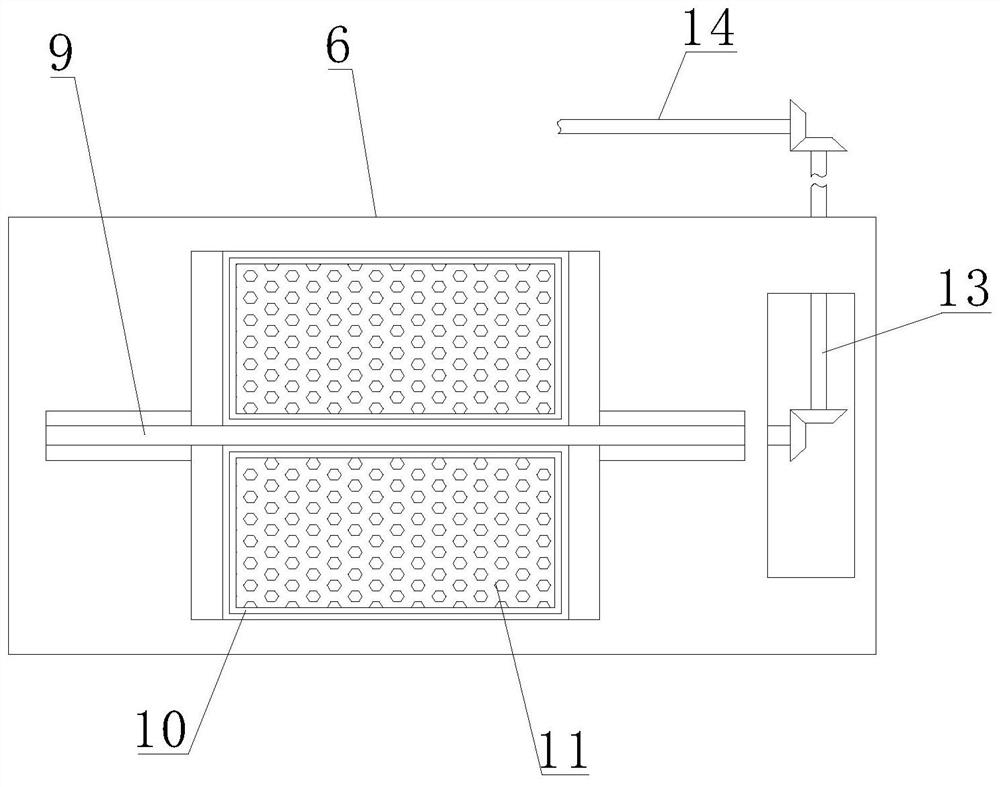

[0059] Such as Figure 9 As shown, this embodiment is basically the same as Embodiment 1. Preferably, two sets of liquid baffles 43 are installed near the top of the fixed pipe 19 by bolts. The liquid baffles 43 are located on both sides of the fixed pipe 19, and The number of each group of liquid baffles 43 is multiple; the liquid baffles 43 are arranged obliquely downward, and the two groups of liquid baffles 43 are arranged at intervals along the vertical direction, the gas moves upward in the fixed pipe 19, and the two sides are obliquely arranged The liquid baffles 43 can block the liquid therein, and by arranging multiple sets of liquid baffles 43 at intervals, the effect of liquid baffles can be significantly improved, which helps to prevent the gas from bringing the processing liquid out.

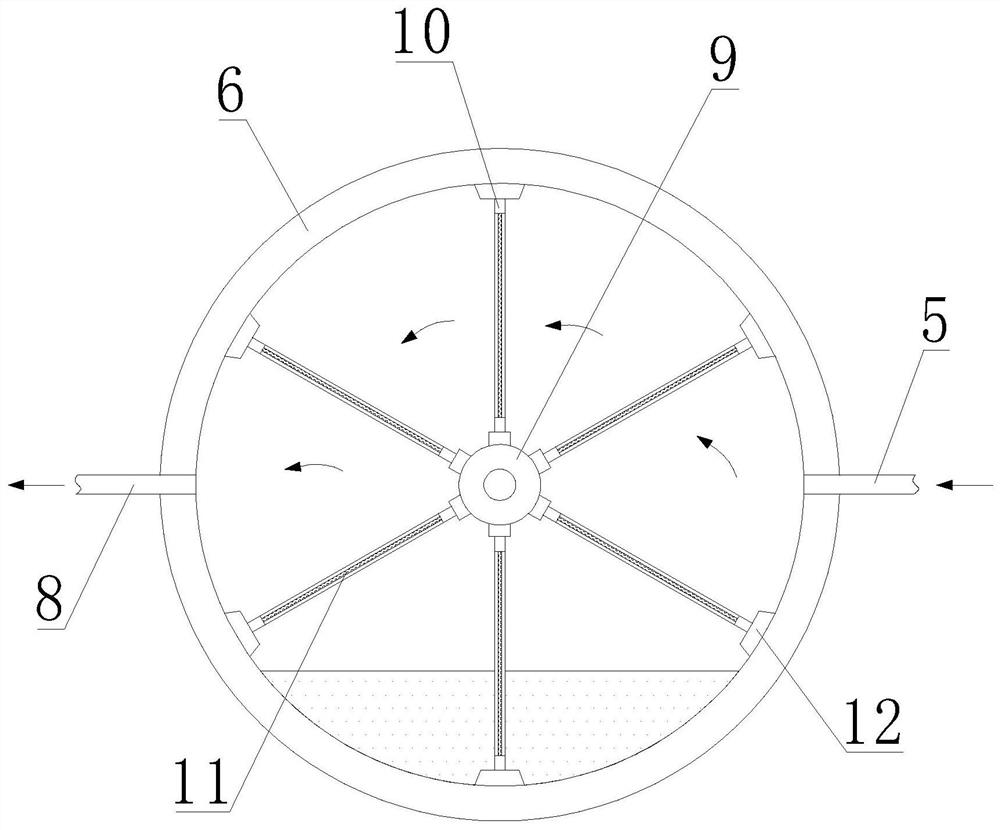

[0060] Working principle of the present invention:

[0061] The exhaust gas input pipe 4 guides the exhaust gas into the trapezoidal exhaust box 32, and the exhaust gas enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com