Structure and load transfer integrated composite material three-point bending clamp and using method

A composite material and three-point bending technology, which is applied in the direction of applying stable bending force to test the strength of materials, analyzing materials, instruments, etc., can solve the problems that cannot be occupied for a long time, three-point bending load and environmental effects cannot be effectively coupled, etc. , to achieve the effect of simple test method, simple structure and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

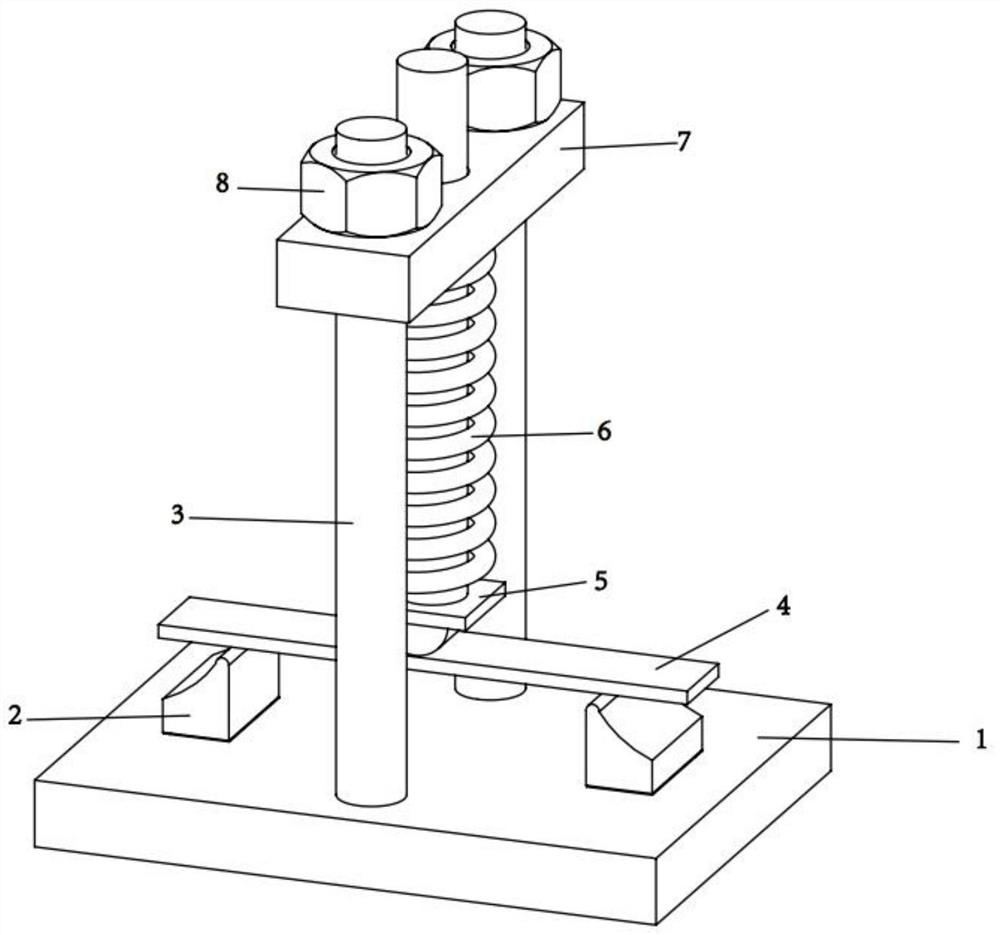

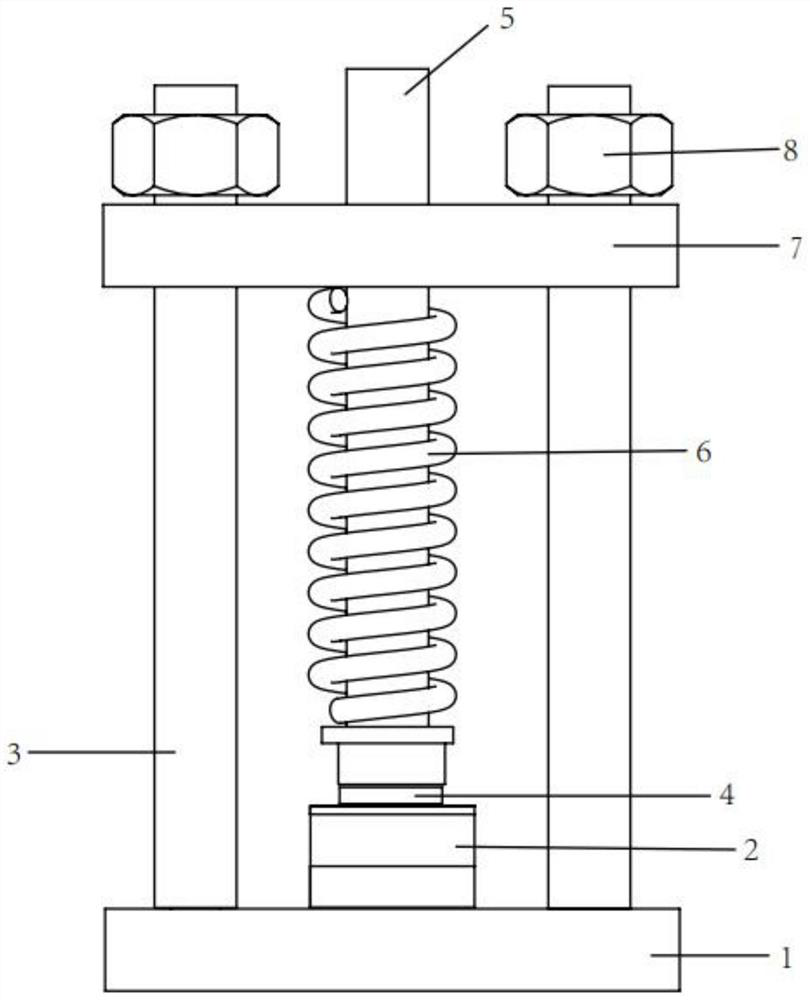

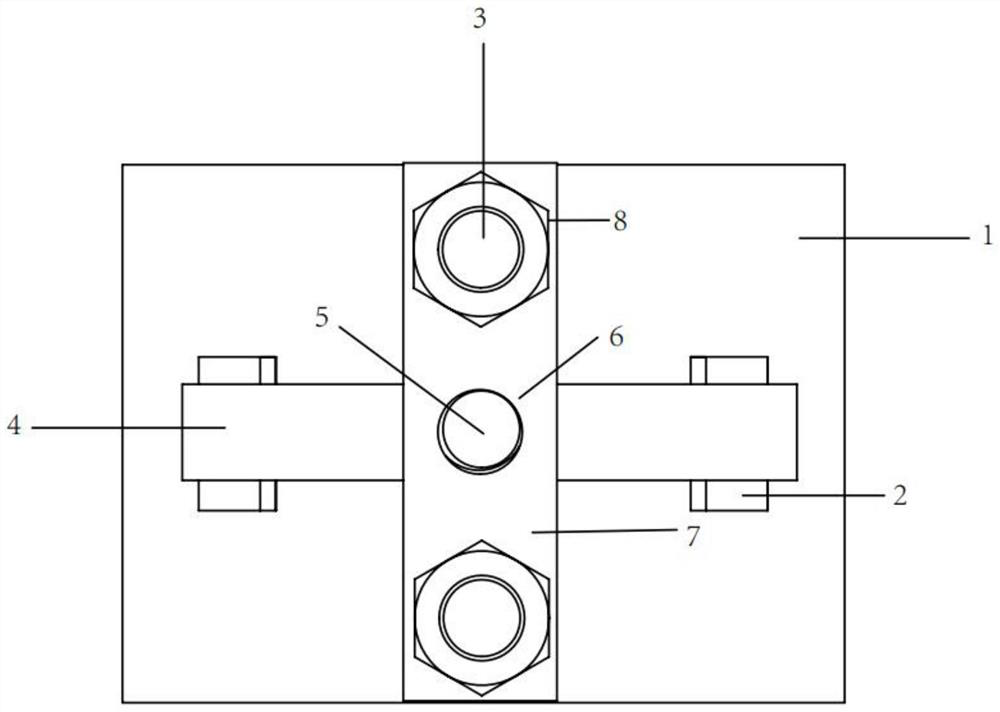

[0038] Such as Figures 1 to 4As shown, this embodiment provides a composite material three-point bending loading fixture with integrated structure and load, including a base plate 1, a support 2, a column 3, a pressing rod 5, a spring 6, a pressing plate 7 and a nut 8; the base plate There are two pairs of threaded through holes; the support and the column are fixed on the bottom plate; the spring is sleeved on the pressure rod, and the length of the spring is less than the length of the cylindrical section of the pressure rod; the pressure plate is sleeved between the column and the pressure rod Above; the nut is sleeved on the column, and the compression load is applied to the spring on the pressure rod through the pressure plate, and then the load is transmitted to the sample through the pressure head part of the pressure rod.

[0039] The bottom plate 1 of the three-point bending load fixture is in the shape of a cuboid, and two pairs of threaded through holes are opened ...

Embodiment 2

[0049] This embodiment provides a method for using a composite material three-point bending loading fixture with integrated structure and load, including the following steps:

[0050] The composite material sample 4 is a resin-based composite material plate with carbon fiber, glass fiber, aramid fiber, basalt fiber, etc. as reinforcements, and the thickness of the plate is 2mm-4mm, preferably 2mm; the length of the composite material sample 4 is 60mm -110mm, preferably 80mm, the width of the composite material sample 4 is 10mm-30mm, preferably 12mm. The number of composite material samples 4 in the same batch is 10 or more.

[0051] Further, 5 composite material samples of the same batch are randomly selected for a three-point bending performance test, and the three-point bending of these 5 composite material samples is performed until fracture is calculated to calculate the ultimate three-point bending strength of the composite material sample .

[0052] After assembling th...

Embodiment 3

[0069]This embodiment relates to a composite material test method for a composite material three-point bending loading fixture with integrated structure and load carrying, which specifically includes the following steps:

[0070] Composite material sample 4 with ceramic as the matrix, sample 4 has a length of 170 mm, a width of 10 mm, and a thickness of 5 mm. The composite material sample 4 was positioned with a three-point bending fixture, and the compression amount was applied to the spring 6, so that the load strength applied by the spring 6 to the composite material sample 4 was 30% of the ultimate three-point bending load of the composite material. Place the adjusted three-point bending fixture in the ultra-low temperature bearing cooling box, set the temperature at -50°C, and test for 7 days. After the test, wait for the three-point bending fixture to return to room temperature, remove the composite material sample 4 from the three-point bending fixture and perform a thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic coefficient | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com