Fast-charging lithium air battery with self-catalytic activity

A lithium-air battery and self-catalysis technology, which is applied to battery electrodes, fuel cell half-cells, secondary battery-type half-cells, circuits, etc., can solve the problem of high cost, poor stability and low energy efficiency of positive electrode catalysts and other problems, to achieve the effect of improving fast charging performance, high energy conversion efficiency, and low charging overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

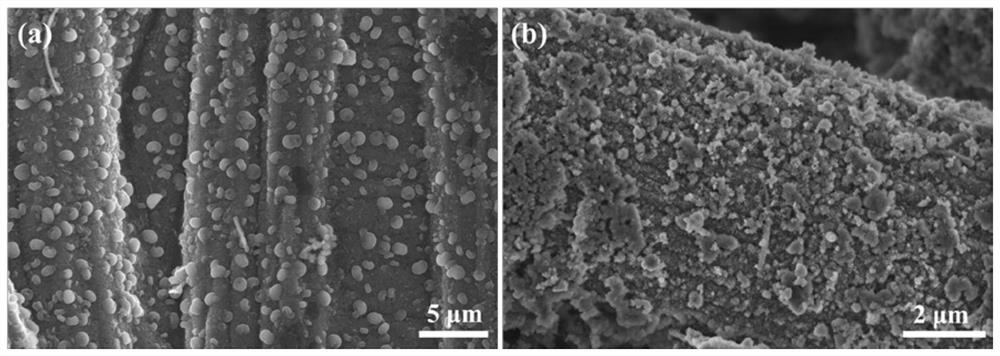

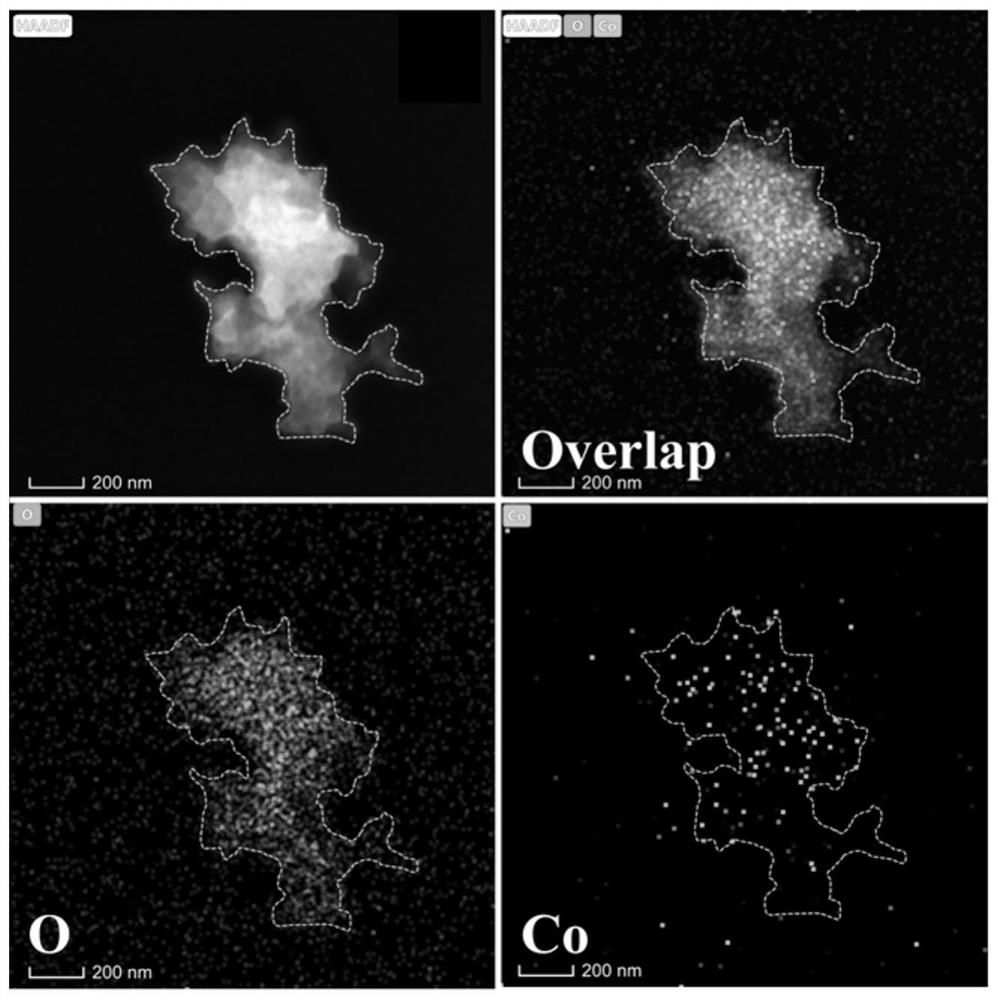

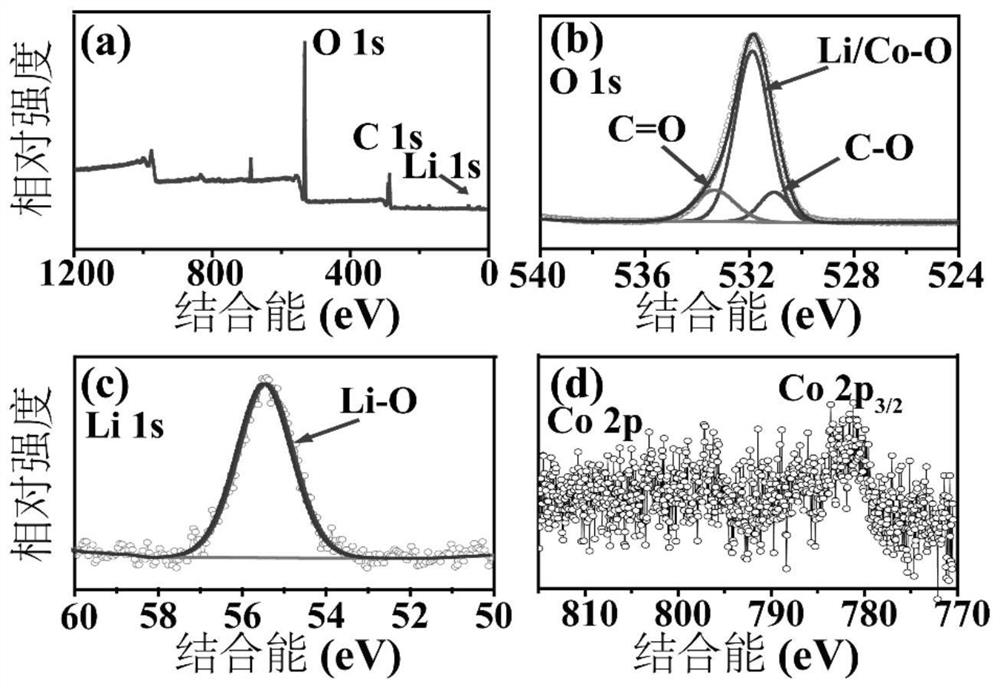

Embodiment 1

[0051] (S1) Preparation of electrolyte: preparation of basic electrolyte: tetraethylene glycol dimethyl ether (TEGDME), 1,3-dioxolane (DOL) and 1H,1H,5H-octafluoropentyl-1 , 1,2,2-Tetrafluoroethyl ether was mixed according to the volume ratio of 20:5:2 to obtain a mixed ether. Dissolve LiTFSI in the above mixed ether to prepare a basic electrolyte with a concentration of 1M LiTFSI. CoCl 2 Put it into 1MLiTFSI / mixed ether for soaking, seal and stir until the cobalt salt is completely dissolved to obtain an electrolyte containing metal cobalt, and adjust the CoCl 2 The amount of input makes Co 2+ The concentration is 0.5M

[0052] (S2) Assemble the metal-air battery with the air electrode and the prepared electrolyte: first install the negative electrode in the order of negative electrode shell, spring sheet, gasket, and 15.6*0.5mm (~50mg) lithium sheet, and drop 100mL of the above-mentioned The basic electrolyte (1M LiTFSI / mixed ether) of step (S1), seal the negative pole (...

Embodiment 2

[0063] Other operations and conditions are the same as in Example 1, the difference is that the electrolyte is prepared in step (S1), and the CoCl 2 The amount of addition, so that the Co in the electrolyte containing metallic cobalt 2+ The concentration is 0.2M.

Embodiment 3

[0065] Other operations and conditions are the same as in Example 1, the difference is that the electrolyte is prepared in step (S1), and the CoCl 2 The amount of addition, so that the Co in the electrolyte containing metallic cobalt 2+ The concentration is 0.1M.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com