Method for recovering fluoride salt from aluminum electrolysis overhaul slag through pressurized alkaline leaching

A technology of pressurized alkali leaching and overhaul slag, which is applied in the field of harmless disposal of aluminum electrolysis overhaul slag and comprehensive utilization of resources, and can solve the problem of harmless disposal and comprehensive utilization of resources without waste cathode carbon blocks and waste tank linings, and equipment investment Large size, complex process and other problems, to achieve the effect of improving the efficiency of pressure leaching, saving production costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

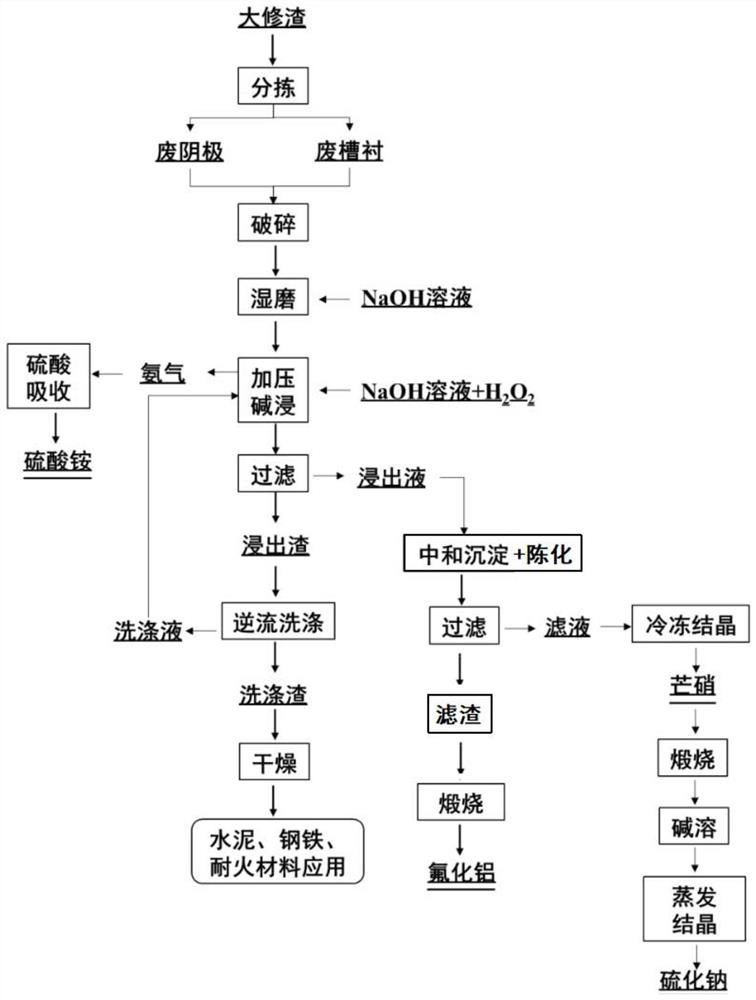

[0028]A method for recovering fluoride salts by pressurized alkaline leaching of aluminum electrolytic overhaul slag, wherein the aluminum electrolytic overhaul slag is the waste cathode and waste tank liner generated during the maintenance and replacement of the electrolytic cell cathode lining in the production process of electrolytic aluminum, and the overhaul slag is added The method of recovering fluoride salt by pressure alkaline leaching, such as figure 1 As shown, the steps are as follows:

[0029] (1) Carry out two-stage crushing of the spent cathode and the waste tank lining, the first-stage crushing to a particle size of ≤400m, and the second-stage crushing to a particle size of ≤10mm, accounting for more than 90% of the total material weight;

[0030] (2) The waste cathode and waste tank lining particles obtained in the above step (1) are respectively added to NaOH solution with a volume concentration of 100g / L for wet ball milling, the liquid-solid ratio is contro...

Embodiment 2

[0045] A method for recovering fluoride salt by pressurized alkaline leaching of aluminum electrolysis overhaul slag, the steps are as follows:

[0046] (1) Carry out two-stage crushing of the spent cathode and the waste tank lining, the first-stage crushing to a particle size of ≤400m, and the second-stage crushing to a particle size of ≤10mm, accounting for more than 90% of the total material weight;

[0047] (2) The waste cathode and waste tank lining particles obtained in the above step (1) are respectively added to a NaOH solution with a volume concentration of 100g / L for wet ball milling, the liquid-solid ratio is controlled at 0.5:1, and the ball milling time is 30min to obtain a waste cathode Slurries and waste tank lining slurries. The material below 200 mesh in the slurry accounts for more than 90% of the total solid phase weight;

[0048] (3) Send the waste cathode slurry and the waste tank lining slurry obtained in the above step (2) into the closed leaching equip...

Embodiment 3

[0054] A method for recovering fluoride salt by pressurized alkaline leaching of aluminum electrolysis overhaul slag, the steps are as follows:

[0055] (1) Carry out two-stage crushing of the spent cathode and the waste tank lining, the first-stage crushing to a particle size of ≤400m, and the second-stage crushing to a particle size of ≤10mm, accounting for more than 90% of the total material weight;

[0056] (2) The waste cathode and waste tank lining particles obtained in the above step (1) are respectively added to a NaOH solution with a volume concentration of 100g / L for wet ball milling, the liquid-solid ratio is controlled at 0.7:1, and the ball milling time is 20min to obtain a waste cathode Slurries and waste tank lining slurries. The material below 200 mesh in the slurry accounts for more than 90% of the total solid phase weight;

[0057] (3) Send the waste cathode slurry and the waste tank lining slurry obtained in the above step (2) into the closed leaching equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com