Intelligent production scheme for finishing off-line procedure of medium plate

An off-line and finishing technology, which is applied in the field of steel production, can solve problems such as high quality problems, high risks, and restrictions on production efficiency, and achieve the effects of reducing the problem of cutting short lengths, avoiding civil engineering and equipment line transformation, and improving equipment interoperability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

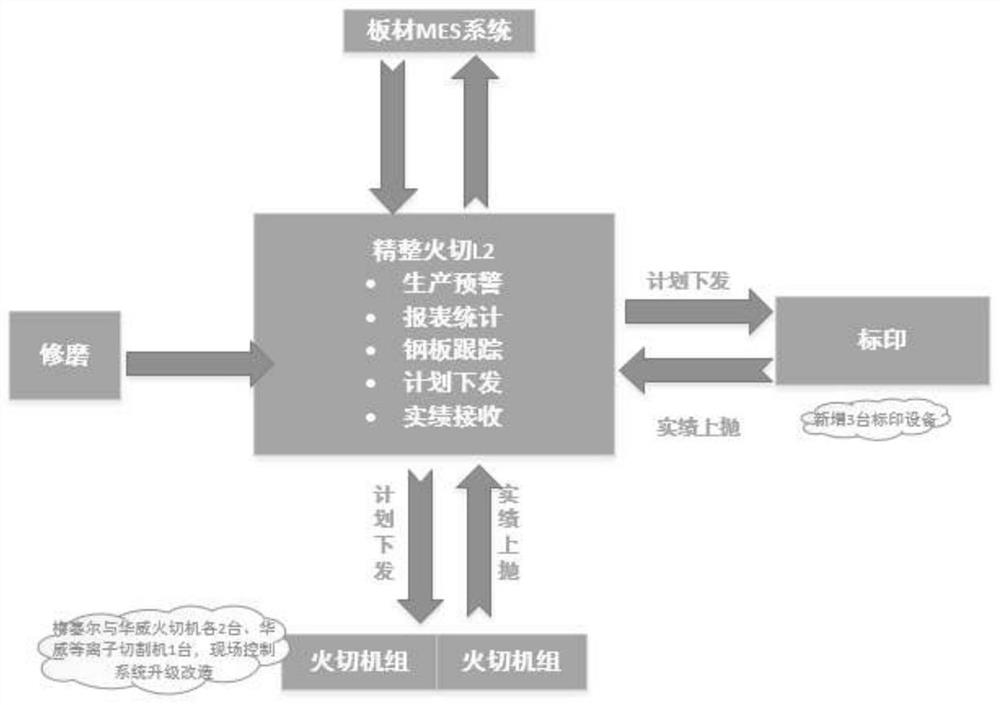

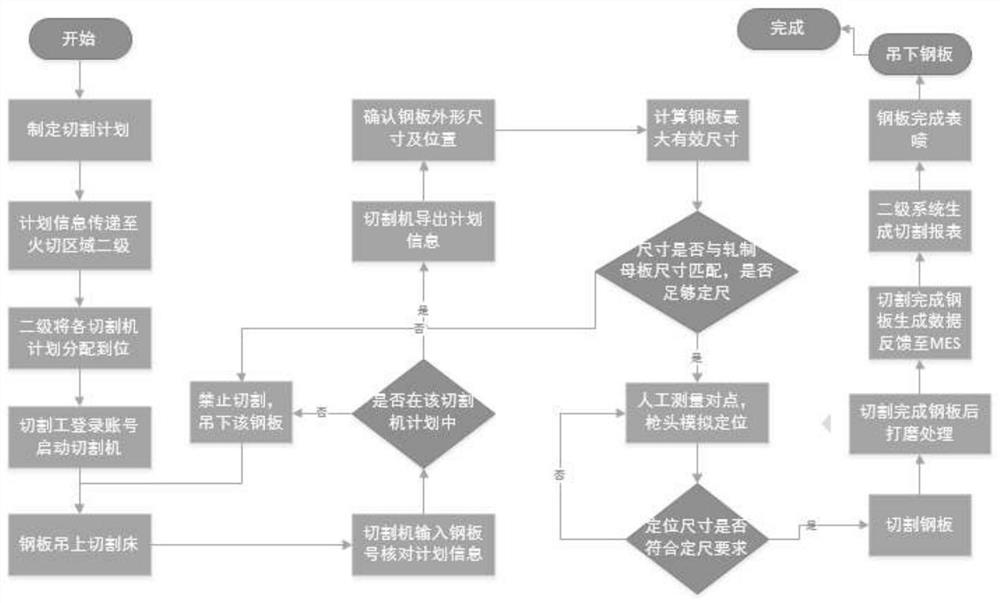

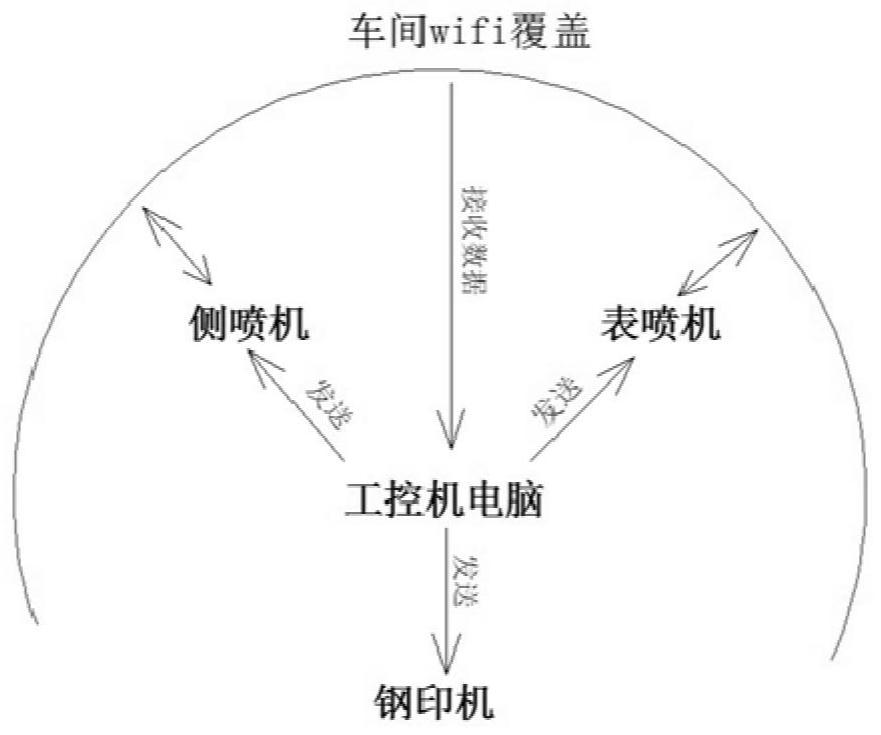

[0052] This embodiment provides an intelligent production scheme for the off-line process of medium and heavy plate finishing, such as figure 1 , using the wireless network covered by the wide and thick plate factory as a data transmission channel, establish an offline secondary system and database, the third-level design plan release interface, and the second-level will send the received plan to the cutting machine and marking machine for production, and through Data feedback generates production reports, specifically:

[0053] Plan arrangement: All offline production plan arrangement and distribution are completed in the three-level system, and are sent directly to the cutting machine, and the optimal cutting plan is matched according to the capabilities and characteristics of each device to maximize production capacity, and the system limits the cutting plan of the cutting machine The outer steel plate ensures the execution of the plan and the fulfillment of the contract; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com