Desliming wastewater treatment process

A waste water treatment, waste water technology, applied in the direction of water/sludge/sewage treatment, water/sewage treatment, sedimentation treatment, etc., can solve the problems of inaccurate sampling, sampling results cannot represent the quality of influent water, and the impact of subsequent sewage treatment processes, etc. , to achieve the effects of accelerating sedimentation, reducing desliming production costs, and accelerating sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

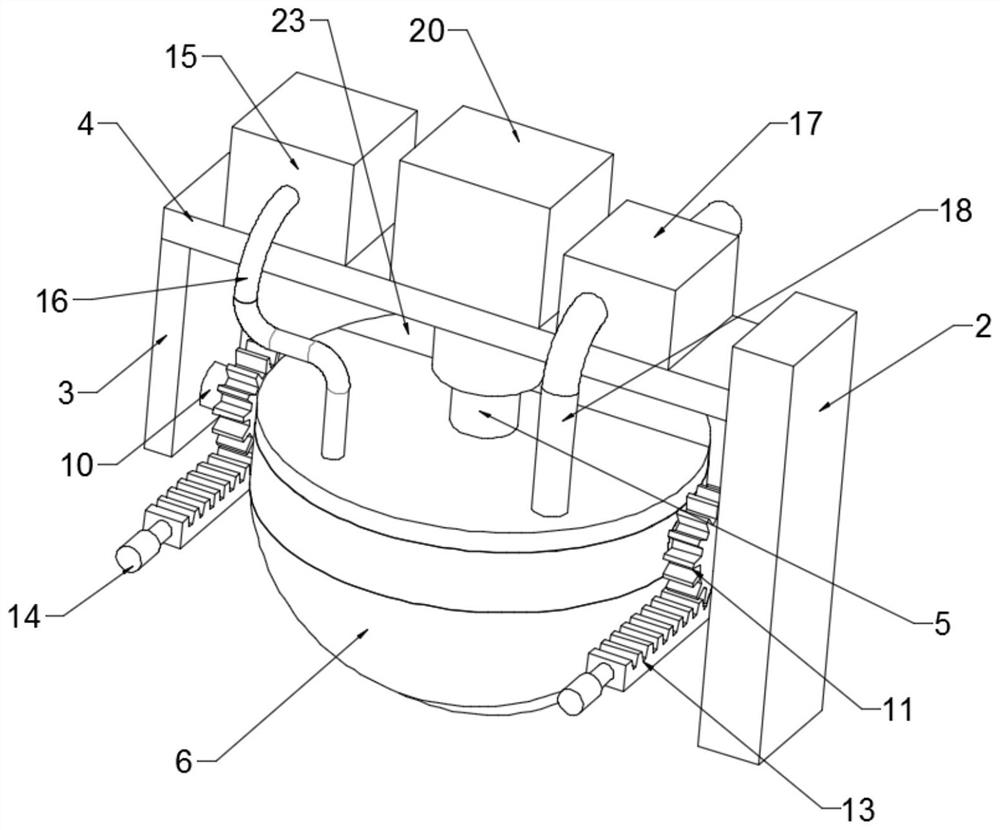

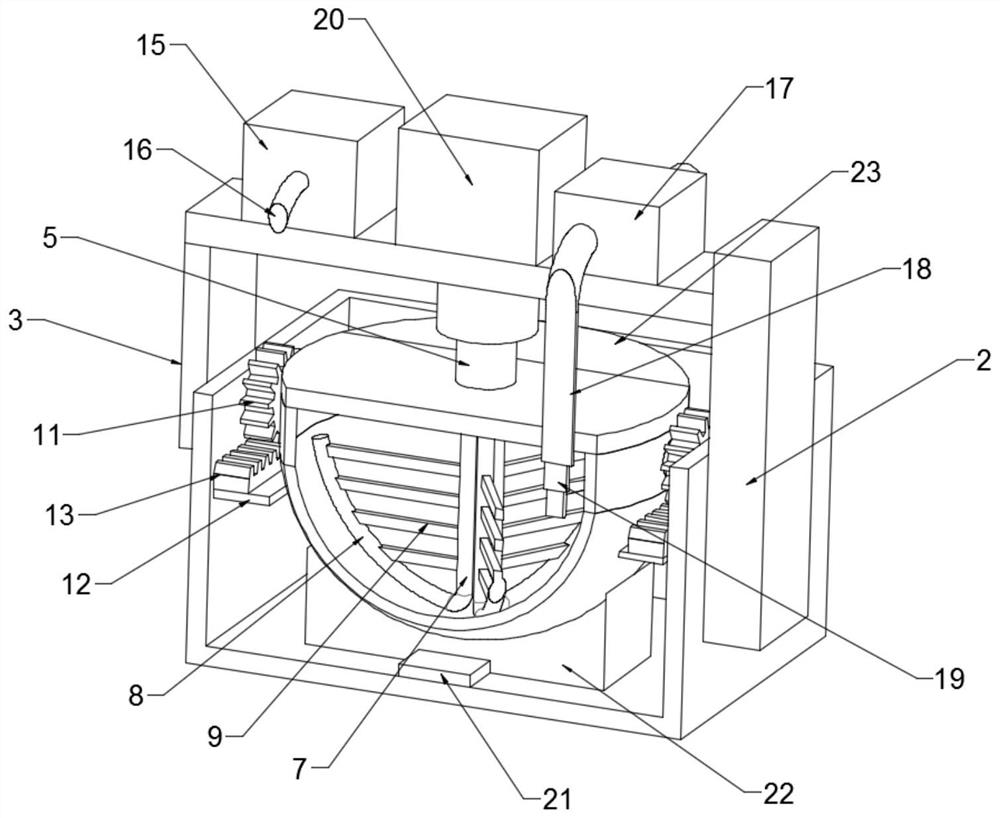

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0030] A desliming wastewater treatment process, the desliming wastewater includes the filtered water obtained when the excess sludge is dewatered and the wastewater obtained after rinsing the filter cloth of the deslimer; the filtered water obtained when the excess sludge is dewatered and the rinsed deslimer The waste water obtained after filtering the cloth is fully mixed to obtain mixed water, which is pumped into the mud storage tank. The mixed water is pumped into the middle of the sludge storage tank, so as to avoid disturbing the settled sludge at the bottom as much as possible.

[0031] As an improvement, the mud storage tank includes a mud storage tank body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com