Densified silica fume composite admixture and application thereof in high-performance concrete

A high-performance concrete and composite admixture technology, which is applied in the fields of climate sustainability, sustainable waste treatment, solid waste management, etc. Post-strength, improved workability and strength, effect of improved strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

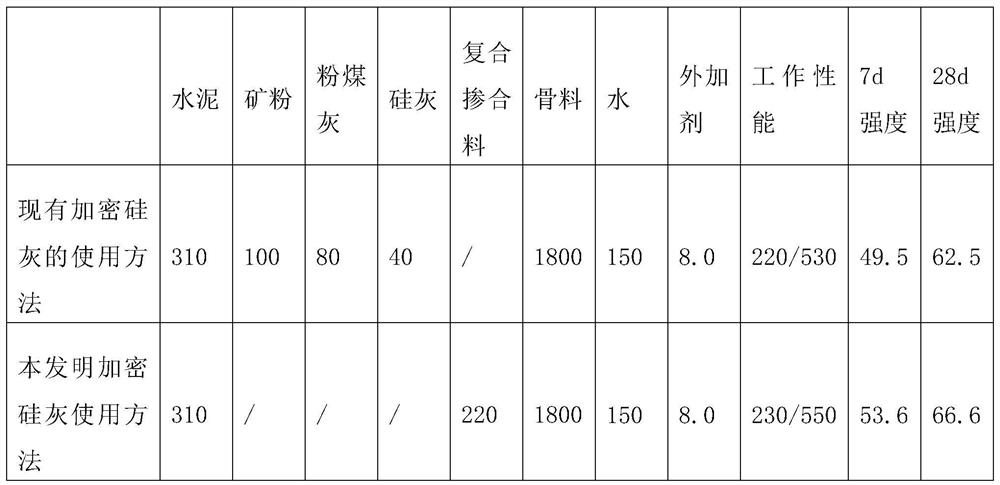

[0025] The technical solution of the present invention is further illustrated below through specific examples.

[0026] 1. Embodiment

[0027] 1) Grinding preparation of composite admixture:

[0028] The raw materials were weighed according to mass percentage, including 18% densified silica fume, 55% limestone, 10% manganese slag, and 17% nickel slag.

[0029] Then the raw materials are input into the mill for grinding, and the grinding time of the materials in the mill is 20-30min, and the fineness of the composite admixture is controlled to 45um and the sieve residue is 15+2%. During the grinding process, the chemical analysis of the compound admixture is carried out, and according to the detected composition of the grinding material, the feeding speed of the encrypted silica fume is adjusted in real time to ensure the accuracy of the measurement of the encrypted silica fume in the composite admixture.

[0030] 2) After the composite admixture is transported to the commerc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com