Repair method for damaged SiC coating carbon/carbon composite material

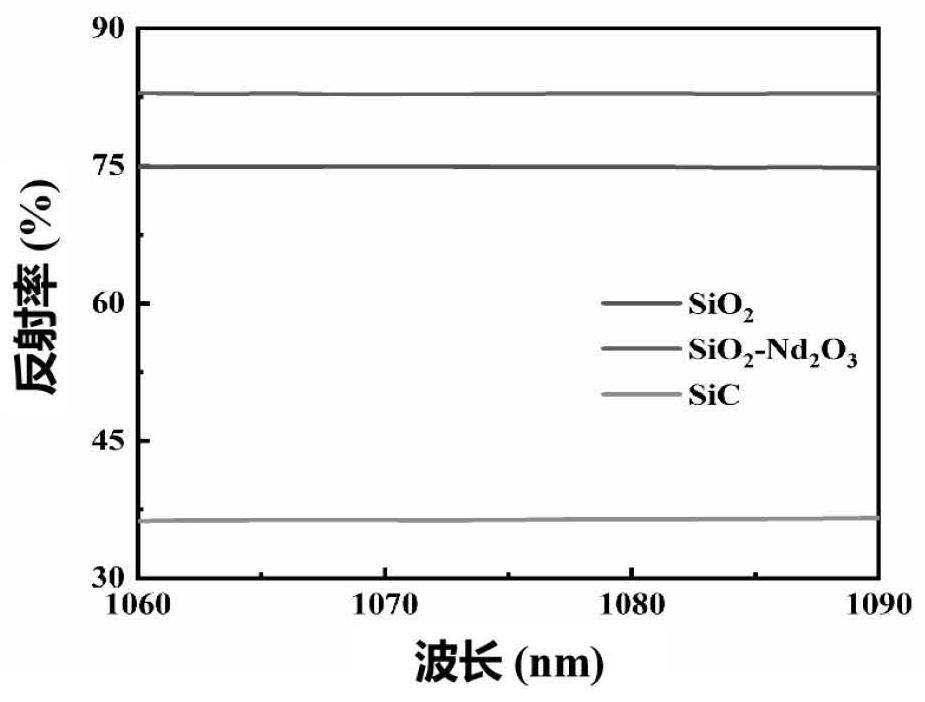

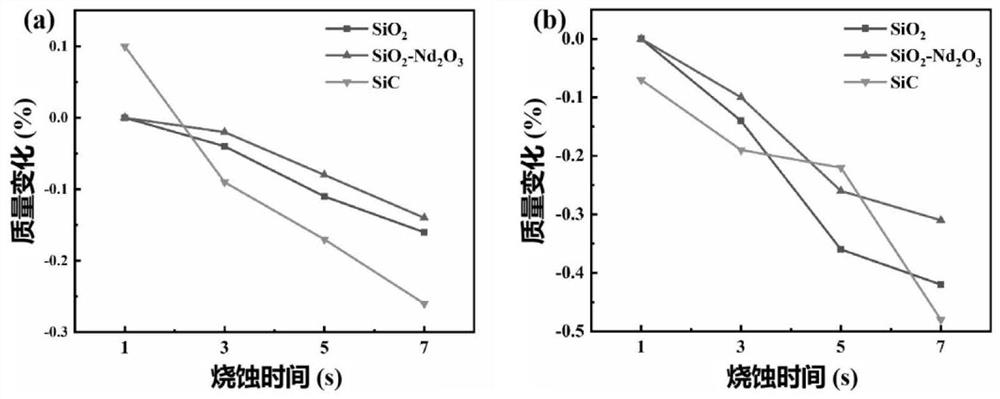

A carbon composite material and repair method technology, applied in the field of SiO2-Nd2O3/Si-SiC repair system, can solve the problems of C/C composite material matrix oxidation and mechanical property decline, heating of SiC coating, poor ablation resistance and other problems , to achieve the effect of excellent laser reflection ability, smooth surface and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Pretreatment: Along the surface of the damaged area, file and polish the damaged part of the SiC-coated C / C composite material to remove the coating in this area until the C / C composite material matrix is exposed, and the sample is ultrasonically cleaned and baked Dry and set aside.

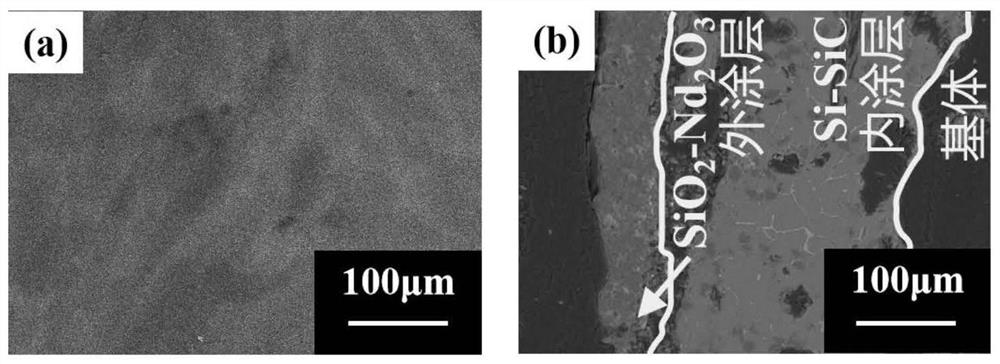

[0031] 2) Powder preparation: Weigh 55% of Si powder, 30% of SiC powder and 15% of C powder, ball mill and mix for 4 hours as the inner coating powder for later use; in addition, weigh the mass percentage 95% SiO 2 powder with 5% Nd 2 o 3 powder, ball milling and mixing for 4 hours, put it into a muffle furnace, heat up from room temperature to 1773K with the furnace in an air environment, continue heat treatment for 2 hours, and then take it out and air-cool it to obtain SiO 2 -Nd 2 o 3 Block materials, for the convenience of subsequent repairs, are ground into powders and used as outer coating powders for later use.

[0032] 3) Damage repair: Use anhydrous ethanol as a solvent...

Embodiment 2

[0035] 1) Pretreatment: Along the surface of the damaged area, file and polish the damaged part of the SiC-coated C / C composite material to remove the coating in this area until the C / C composite material matrix is exposed, and the sample is ultrasonically cleaned and baked Dry and set aside.

[0036] 2) Powder preparation: Weigh 55% of Si powder, 30% of SiC powder and 15% of C powder, ball mill and mix for 4 hours as the inner coating powder for later use; in addition, weigh the mass percentage 95% SiO 2 powder with 5% Nd 2 o 3 powder, ball milling and mixing for 4 hours, put it into a muffle furnace, heat up from room temperature to 1773K with the furnace in an air environment, continue heat treatment for 2 hours, and then take it out and air-cool it to obtain SiO 2 -Nd 2 o 3 Block materials, for the convenience of subsequent repairs, are ground into powders and used as outer coating powders for later use.

[0037] 3) Damage repair: Use anhydrous ethanol as a solvent...

Embodiment 3

[0040] 1) Pretreatment: Along the surface of the damaged area, file and polish the damaged part of the SiC-coated C / C composite material to remove the coating in this area until the C / C composite material matrix is exposed, and the sample is ultrasonically cleaned and baked Dry and set aside.

[0041] Powder preparation: Weigh 55% of Si powder, 30% of SiC powder and 15% of C powder, and mix them by ball milling for 4 hours as the inner coating powder for later use; in addition, weigh the mass percentage of 95% SiO 2 powder with 5% Nd 2 o 3 powder, ball milling and mixing for 4 hours, put it into a muffle furnace, heat up from room temperature to 1773K with the furnace in an air environment, continue heat treatment for 2 hours, and then take it out and air-cool it to obtain SiO 2 -Nd 2 o 3 Block materials, for the convenience of subsequent repairs, are ground into powders and used as outer coating powders for later use.

[0042] 3) Damage repair: Use anhydrous ethanol a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com