Non-liquid-phase production method of phthalonitrile

A technology of phthalonitrile and its production method, which is applied in the direction of chemical instruments and methods, ammonium nitrate, carboxylic acid nitrile purification/separation, etc., can solve the problems of increasing by-products, loss of products, excessive nitrogen oxides, etc., and achieve The effect of avoiding hydrolysis loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

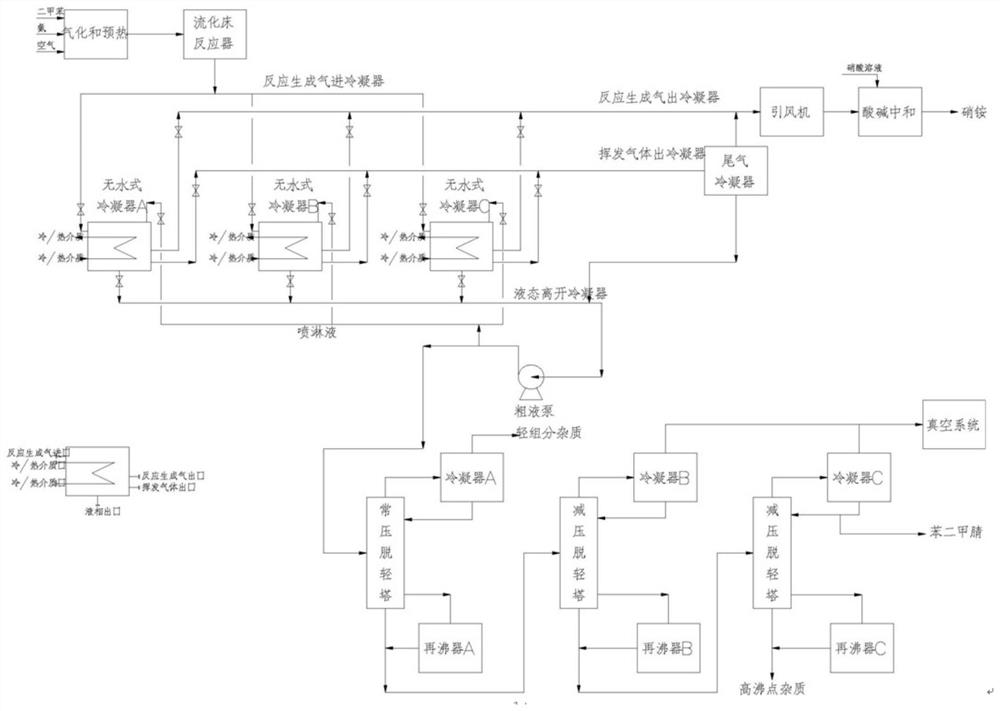

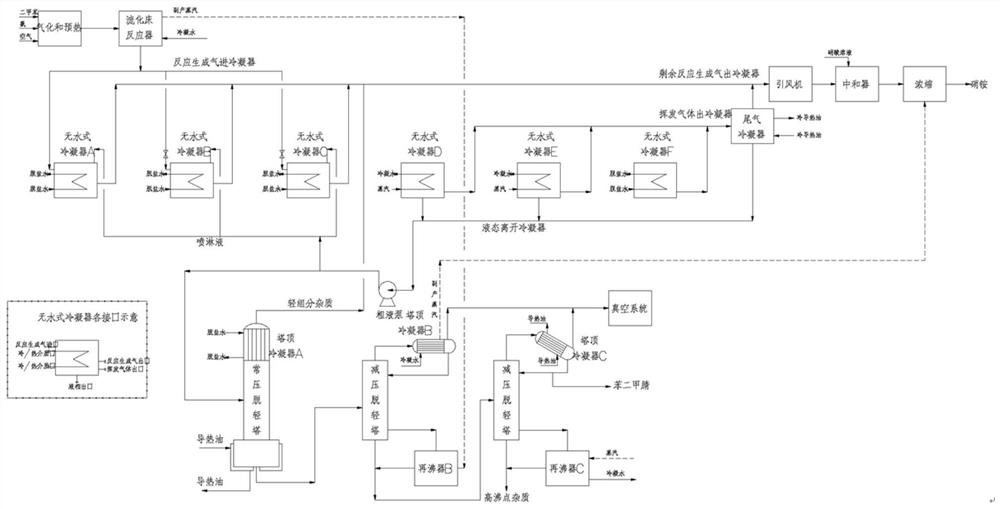

Image

Examples

Embodiment 1

[0029]P-xylene, ammonia and air with a molar ratio of 1:6:34, after gasification and preheating, enter the fluidized bed reactor to generate dicyanophthalonitrile and water. A U-shaped coil is installed in the reactor, and condensed water is introduced to remove the heat of reaction by producing steam to maintain a reaction temperature of 390°C. The reaction pressure is 15kPa(G). The reaction product gas passes through the water-free condensers A, B, and C in step 1. Use 40°C desalinated water in the heat exchange tubes of anhydrous condensers A, B, and C to remove heat, and control the temperature in the shells of anhydrous condensers A, B, and C to 50°C. Part of the liquid from the crude liquid pump is returned to the tops of the anhydrous condensers A, B, and C for spraying. At this time, the inlet / outlet of the reaction product gas of the anhydrous condensers D and E has been closed, and it is in the process of step 2. Steam at 180°C is introduced into the heat exchange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com