A kind of expansive phytate flame retardant, flame retardant epoxy resin and its preparation method and application

A technology of epoxy resin and phytate, applied in the field of flame retardant, can solve the problems of high hazard and high pollution of synthesis, and achieve the effects of low price, wide source and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Expandable phytate flame retardant 1

[0031] A kind of preparation method of expansive phytate flame retardant, the steps are:

[0032] DOPO (21.6 g, 0.1 mol) was added into a 250 ml flask, and then butanol was added, and the temperature was raised to 50° C. under magnetic stirring. After DOPO was completely dissolved, aminostyrene (13.09 g, 0.11 mol) was added dropwise and reacted at 50° C. for 5 h. At 30° C., phytic acid (72.6 g, 0.11 mol) was added dropwise to react for 0.5 h. Butanol was then removed by rotary evaporation, and the obtained solid was dried at 80° C. for 8 h.

Embodiment 2

[0033] Example 2: Expandable phytate flame retardant 2

[0034] A kind of preparation method of expansive phytate flame retardant, the steps are:

[0035] DOPO (12.96 g, 0.06 mol) was added into a 250 ml flask, and then methanol was added, and the temperature was raised to 100° C. under magnetic stirring. After DOPO was completely dissolved, aminopropene (5.14 g, 0.09 mol) was added dropwise and reacted at 120° C. for 10 h. At 120° C., phytic acid (9.9 g, 0.015 mol) was added dropwise to react for 2 h. Methanol was then removed by rotary evaporation, and the obtained solid was dried at 180° C. for 8 h.

Embodiment 3

[0036] Example 3: Expandable Phytate Flame Retardant 3

[0037] A kind of preparation method of expansive phytate flame retardant, the steps are:

[0038] Add DOPO (20.74 g, 0.096 mol) into a 250 ml flask, then add ethanol, stir magnetically and raise the temperature to 80°C. After DOPO was completely dissolved, aminobenzaldehyde (14.54 g, 0.12 mol) was added dropwise and reacted at 90° C. for 8 h. At 70°C, phytic acid (6.6 g, 0.01 mol) was added dropwise to react for 1.5 h. Then the ethanol was removed by rotary evaporation, and the obtained solid was dried at 150° C. for 8 h.

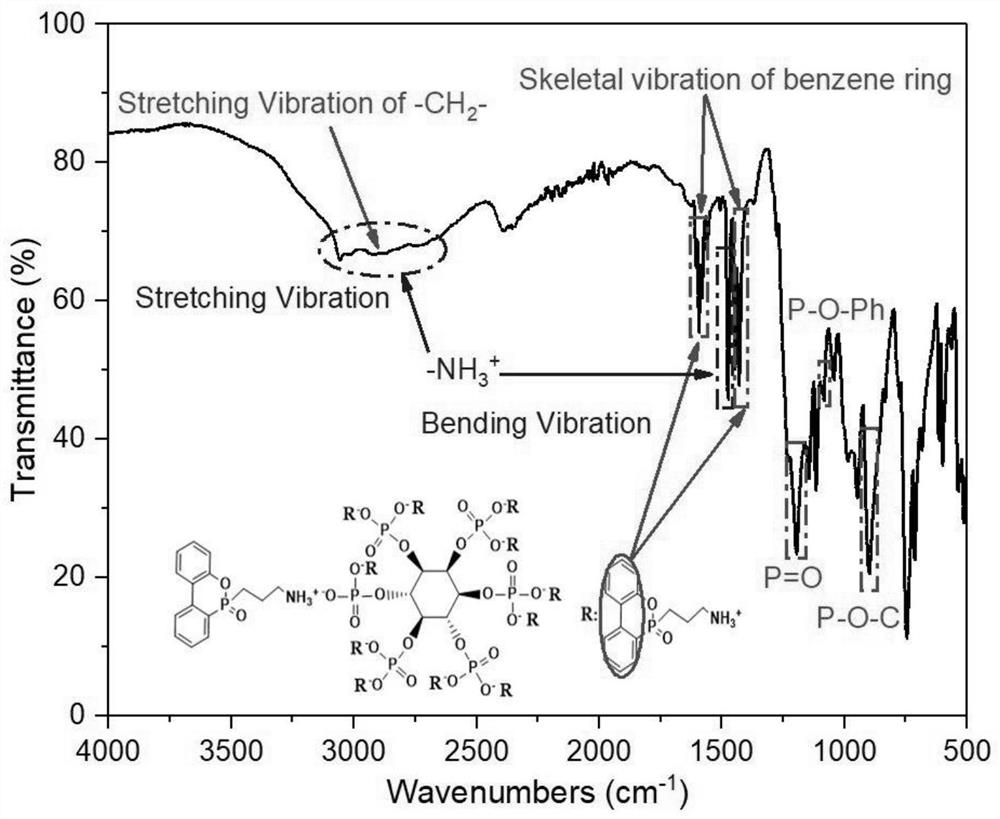

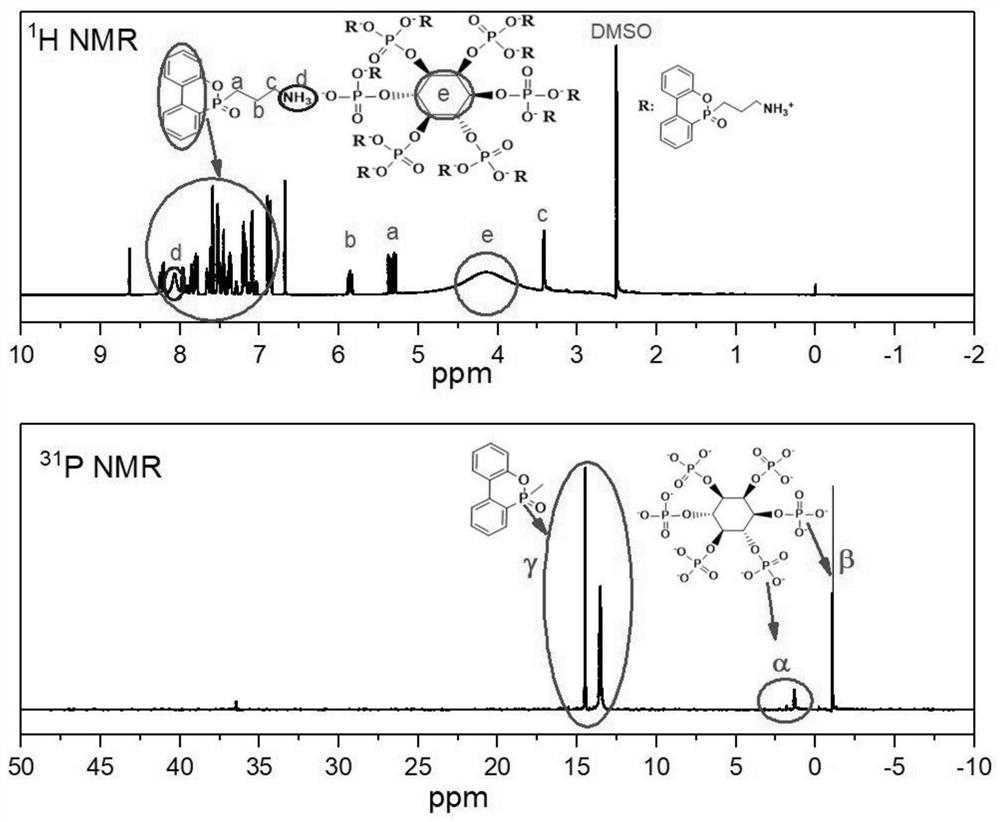

[0039] From attached figure 1 , attached figure 2 It can be seen that, through the process of Example 2, the expandable phytate flame retardant 2 was successfully synthesized. After experimental testing and analysis, the expansive phytate flame retardant 2 is preferred for use in the preparation of flame retardant epoxy resins.

[0040] The following is the use of the expandable phytate flame r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com