High-mixing-amount rubber powder-SBS composite modified asphalt and preparation method thereof

A technology of composite modified asphalt with high content, applied in building components, building insulation materials, construction, etc., can solve the problem of difficulty in increasing the content of rubber powder, limited compatibility of rubber powder and asphalt, and insufficient modification effect Take advantage of other issues to achieve good high and low temperature performance and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

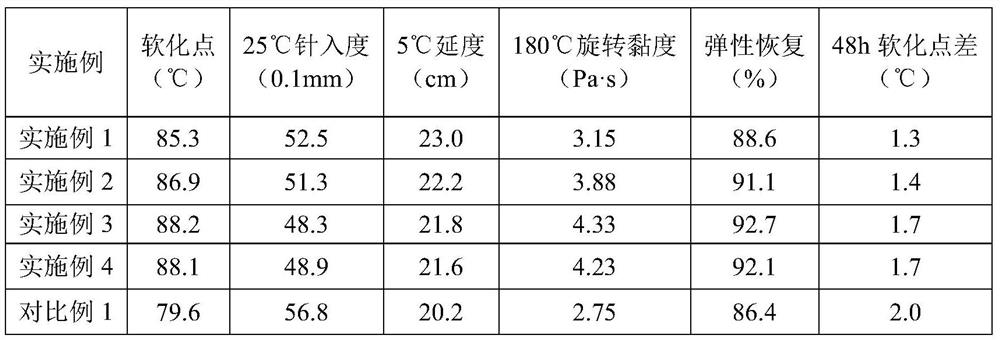

Embodiment 1

[0039] In this embodiment, a high-volume rubber powder-SBS composite modified asphalt is designed, and its components include 100 parts by weight of base asphalt, 34 parts of waste tire rubber powder, 3 parts of SBS, 1.5 parts of cracking agent, aromatic oil Makes 3 servings. The rubber powder used in this embodiment is road-use waste tire vulcanized rubber powder with a relatively high content of natural rubber powder ground and pulverized at room temperature, and the specification of the rubber powder is 40 mesh. The preparation process of high-volume rubber powder-SBS composite modified asphalt in this example is as follows:

[0040] (1) Dehydrate and dry the base asphalt and the modifier respectively. The dehydration temperature of the base asphalt is controlled at 140°C, and the drying temperature of the modifier is controlled at 50°C;

[0041] (2) Pretreatment of rubber powder: Weigh rubber powder, aromatic oil and cracking agent into a sample tank, stir with an electri...

Embodiment 2

[0047]In this embodiment, a high-volume rubber powder-SBS composite modified asphalt is designed, and its components include 100 parts by weight of base asphalt, 38 parts of waste tire rubber powder, 3 parts of SBS, 1.5 parts of cracking agent, aromatic oil Makes 3 servings. The rubber powder used in this embodiment is road-use waste tire vulcanized rubber powder with a relatively high content of natural rubber powder ground and pulverized at room temperature, and the specification of the rubber powder is 40 mesh. The preparation process steps are the same as in Example 1.

Embodiment 3

[0049] In this embodiment, a high-volume rubber powder-SBS composite modified asphalt is designed, and its components include 100 parts by weight of base asphalt, 42 parts of waste tire rubber powder, 3 parts of SBS, 1.5 parts of cracking agent, aromatic oil Makes 3 servings. The rubber powder used in this embodiment is road-use waste tire vulcanized rubber powder with a relatively high content of natural rubber powder ground and pulverized at room temperature, and the specification of the rubber powder is 40 mesh. The preparation process steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com