Colloid palladium activator and preparation method thereof

A technology of colloidal palladium and activator, which is applied in the direction of liquid chemical plating, coating, metal material coating technology, etc., and can solve the problems of low activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of colloidal palladium activator, this colloidal palladium activator is calculated by mass concentration or volume concentration, comprises component: the palladium chloride of 1.0g / L, the stannous chloride of 12g / L, the sodium chloride of 75g / L, 0.1g / L sodium stannate and 10mL / L hydrochloric acid, the balance is ultrapure water.

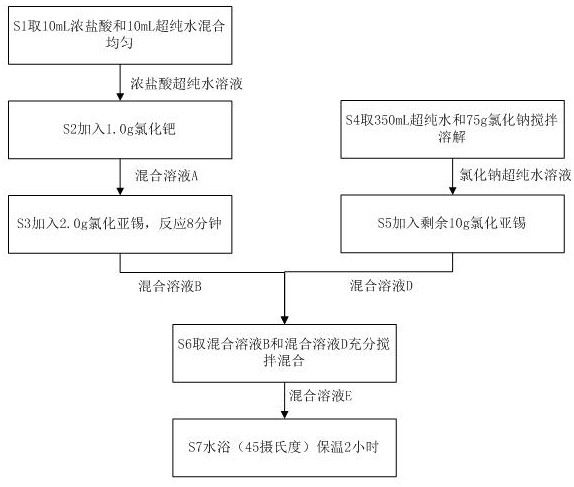

[0025] A method for preparing above-mentioned colloidal palladium activator, it comprises steps:

[0026] S1. Stir and mix 10 mL of concentrated hydrochloric acid and 10 mL of ultrapure water to obtain a mixed solution of concentrated hydrochloric acid and ultrapure water.

[0027] S2. Take 1.0 g of palladium chloride and add it into the mixed solution of concentrated hydrochloric acid and ultrapure water in step S1 to stir and dissolve to obtain mixed solution A.

[0028] S3. Add 2.0 g of stannous chloride to the mixed solution A in step S2 for stirring and dissolving to obtain mixed solution B, and react for 8 minutes.

[0029] S4....

Embodiment 2

[0036] In one of the embodiments, the above-mentioned colloidal palladium activator comprises components: palladium chloride of 1.5g / L, stannous chloride of 26g / L, sodium chloride of 113g / L, stannic acid of 1.4g / L Sodium and 28mL / L hydrochloric acid.

[0037] A method for preparing above-mentioned colloidal palladium activator, it comprises steps:

[0038] S1. Stir and mix 28mL of concentrated hydrochloric acid and 26mL of ultrapure water to obtain a mixed solution of concentrated hydrochloric acid and ultrapure water.

[0039] S2. Take 1.5 g of palladium chloride and add it into the mixed solution of concentrated hydrochloric acid and ultrapure water in step S1 to stir and dissolve to obtain mixed solution A.

[0040] S3. Add 3.0 g of stannous chloride to the mixed solution A in step S2 to stir and dissolve to obtain mixed solution B, and react for 8 minutes.

[0041] S4. Another 530 mL of ultrapure water and 113 g of sodium chloride were stirred and dissolved to obtain a m...

Embodiment 3

[0046] In one of the embodiments, the above-mentioned colloidal palladium activator comprises components: the palladium chloride of 2.0g / L, the stannous chloride of 40g / L, the sodium chloride of 150g / L, the stannic acid of 2.8g / L Sodium and 44mL / L hydrochloric acid.

[0047] A method for preparing above-mentioned colloidal palladium activator, it comprises steps:

[0048] S1. Stir and mix 44mL of concentrated hydrochloric acid and 45mL of ultrapure water to obtain a mixed solution of concentrated hydrochloric acid and ultrapure water.

[0049] S2. Take 2.0 g of palladium chloride and add it into the mixed solution of concentrated hydrochloric acid and ultrapure water in step S1 to stir and dissolve to obtain mixed solution A.

[0050] S3. Add 4.0 g of stannous chloride to the mixed solution A in step S2 to stir and dissolve to obtain mixed solution B, and react for 8 minutes.

[0051] S4. Another 700 mL of ultrapure water and 150 g of sodium chloride were stirred and dissolv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com