High-refractive-index optical glass and preparation device thereof

A technology of optical glass and high refractive index, which is applied in glass/slag layered products, chemical instruments and methods, grain processing, etc. It can solve the problems of increased melting time and incomplete melting, etc., and achieves high refractive index and dispersion, and is convenient Effects of melting and large ionic radius

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific inventions.

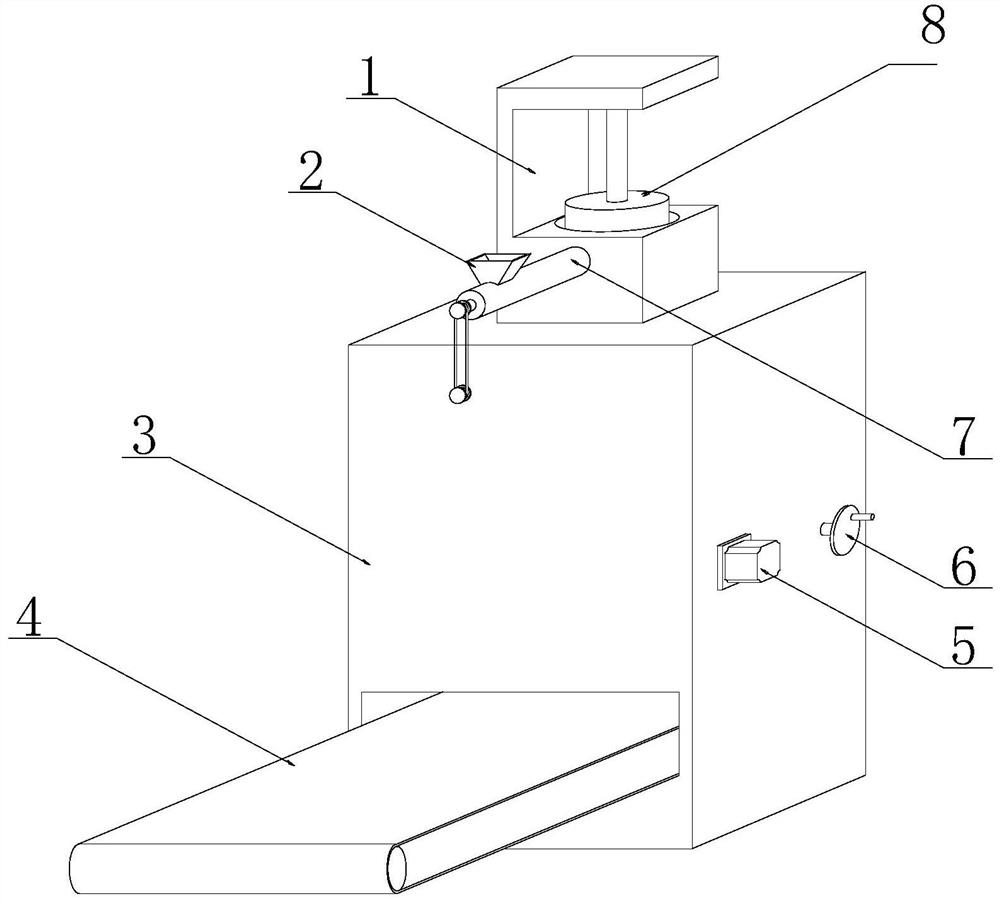

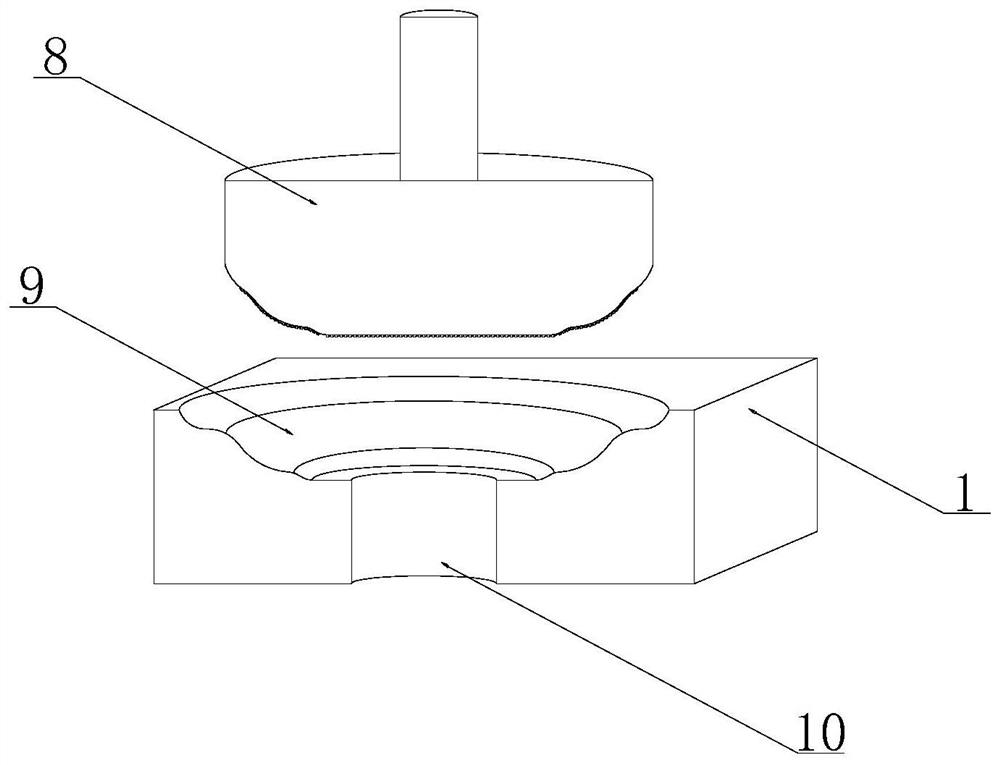

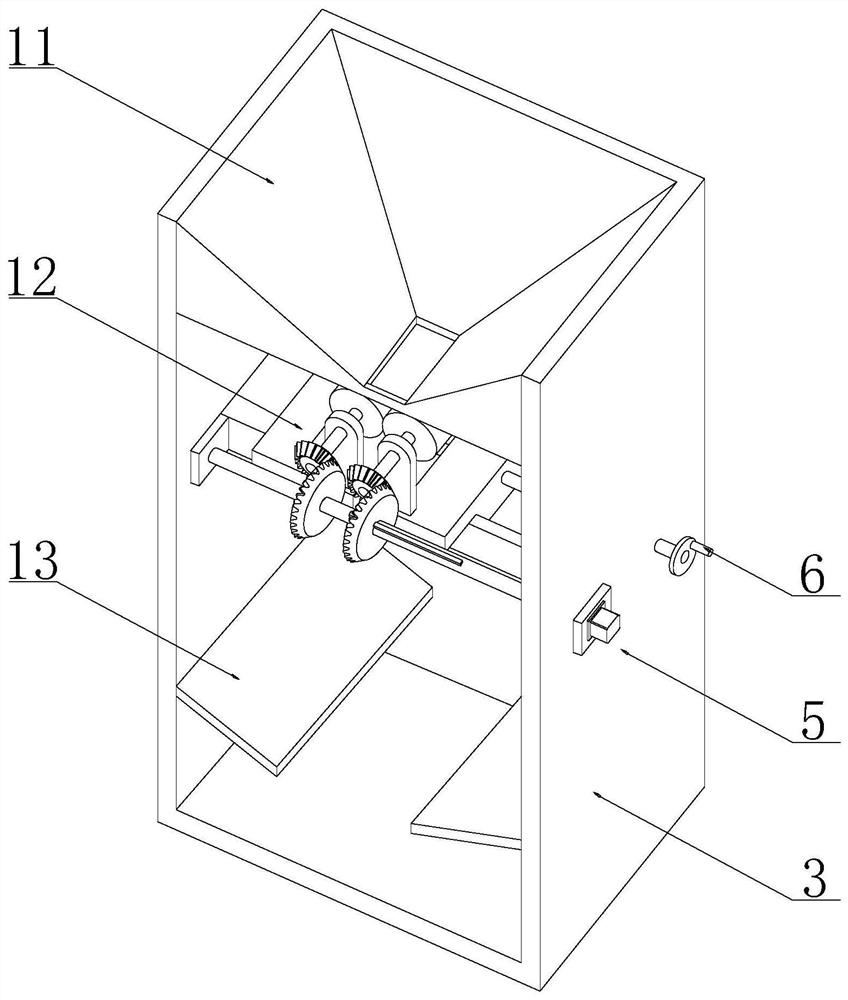

[0027] showing figure 1 , 2 , 4 and 5 provide a kind of optical glass preparation device, comprise grinding box 1, auger 7 is installed on the side of grinding box 1, be provided with feed inlet 2 at the top of auger 7, open in grinding box 1 Grinding tank 9, the inner bottom of grinding box 1 is provided with discharge hole 10, grinding head 8 is placed in grinding tank 9, and the bottom of grinding box 1 is provided with powder secondary grinding mechanism 12, powder secondary grinding mechanism 12 includes installation frame 16, and one end of the upper surface of the mounting frame 16 is fixed with a fixed plate 15, and the other end of the upper surface of the mounting frame 16 is slidably connected with a movable plate 22, and the upper surface of the fixed plate 15 and the movable plate 22 are symmetrically connected. 26, the fixed plate 15 is movably connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com