High-wear-resistance heat dissipation rubber and preparation method thereof

A high wear-resistant, rubber-based technology, applied in fiber chemical characteristics, textiles and papermaking, fiber treatment, etc., can solve the problems of poor rubber wear resistance, product temperature rise, and affect the use effect, so as to increase elasticity and increase Density and the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

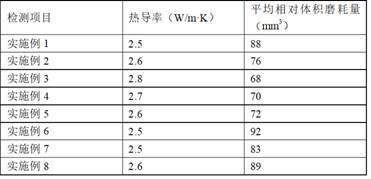

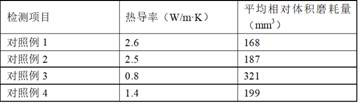

Examples

Embodiment 1

[0055] Mix sorbitan fatty acid ester and polyoxyethylene sorbitan monooleate in a volume ratio of 1:4 to obtain a composite surfactant, then mix the composite surfactant with n-heptane and n-butanol in a volume ratio Mix 10:70:3 to obtain the oil phase, then mix the silica sol with a solid content of 20% and the oil phase at a volume ratio of 1:10, stir with a stirrer at a speed of 800r / min for 40min, and then add a concentration of Adjust the pH to 7 with 1mol / L ammonia water, let the gel react for 12 hours, and then pulverize it to obtain a wet silica airgel; after blending polyacrylonitrile and polymethyl methacrylate at a mass ratio of 9:1 Dissolved in N-N-dimethylformamide to obtain a spinning solution with a mass fraction of 30%, the spinning solution was electrostatically spun at a spinning electrostatic high voltage of 22kV and an injection rate of 0.08mL / min to obtain a blend Fiber filaments: Put the above blended filaments into a high-temperature blast oven, heat and...

Embodiment 2

[0057] Mix sorbitan fatty acid ester and polyoxyethylene sorbitan monooleate in a volume ratio of 1:4 to obtain a composite surfactant, then mix the composite surfactant with n-heptane and n-butanol in a volume ratio Mix 10:70:3 to obtain the oil phase, then mix the silica sol with a solid content of 20% and the oil phase at a volume ratio of 1:10, stir with a stirrer at a speed of 800r / min for 40min, and then add a concentration of Adjust the pH to 7 with 1mol / L ammonia water, let the gel react for 12 hours, and then pulverize it to obtain a wet silica airgel; after blending polyacrylonitrile and polymethyl methacrylate at a mass ratio of 9:1 Dissolved in N-N-dimethylformamide to obtain a spinning solution with a mass fraction of 30%, the spinning solution was electrostatically spun at a spinning electrostatic high voltage of 22kV and an injection rate of 0.08mL / min to obtain a blend Fiber filaments: Put the above blended filaments into a high-temperature blast oven, heat and...

Embodiment 3

[0059] Mix sorbitan fatty acid ester and polyoxyethylene sorbitan monooleate in a volume ratio of 1:4 to obtain a composite surfactant, then mix the composite surfactant with n-heptane and n-butanol in a volume ratio Mix 10:70:3 to obtain the oil phase, then mix the silica sol with a solid content of 20% and the oil phase at a volume ratio of 1:10, stir with a stirrer at a speed of 800r / min for 40min, and then add a concentration of Adjust the pH to 7 with 1mol / L ammonia water, let the gel react for 12 hours, and then pulverize it to obtain a wet silica airgel; after blending polyacrylonitrile and polymethyl methacrylate at a mass ratio of 9:1 Dissolved in N-N-dimethylformamide to obtain a spinning solution with a mass fraction of 30%, the spinning solution was electrostatically spun at a spinning electrostatic high voltage of 22kV and an injection rate of 0.08mL / min to obtain a blend Fiber filaments: Put the above blended filaments into a high-temperature blast oven, heat and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com