Method for culturing grouper cells by using bioreactor

A bioreactor, grouper technology, applied in the biological field, achieves the effect of high cell yield, normal cell shape, and promotion of low biological metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

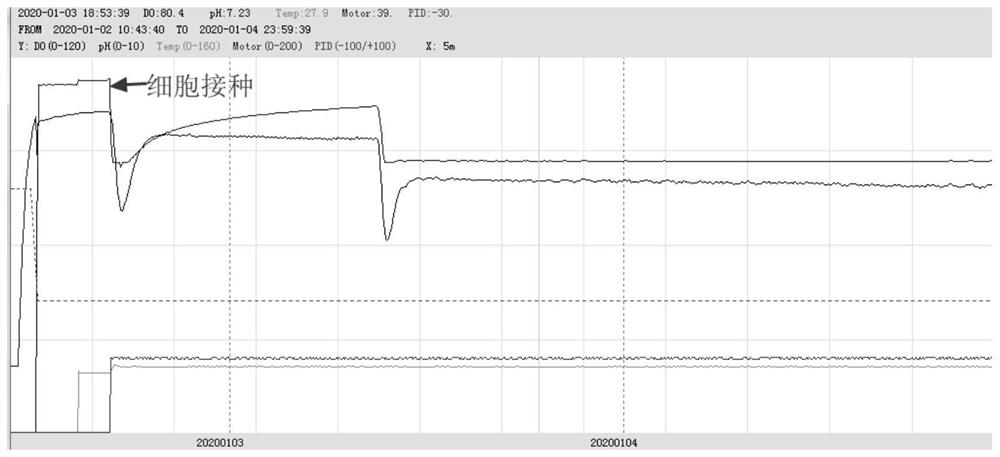

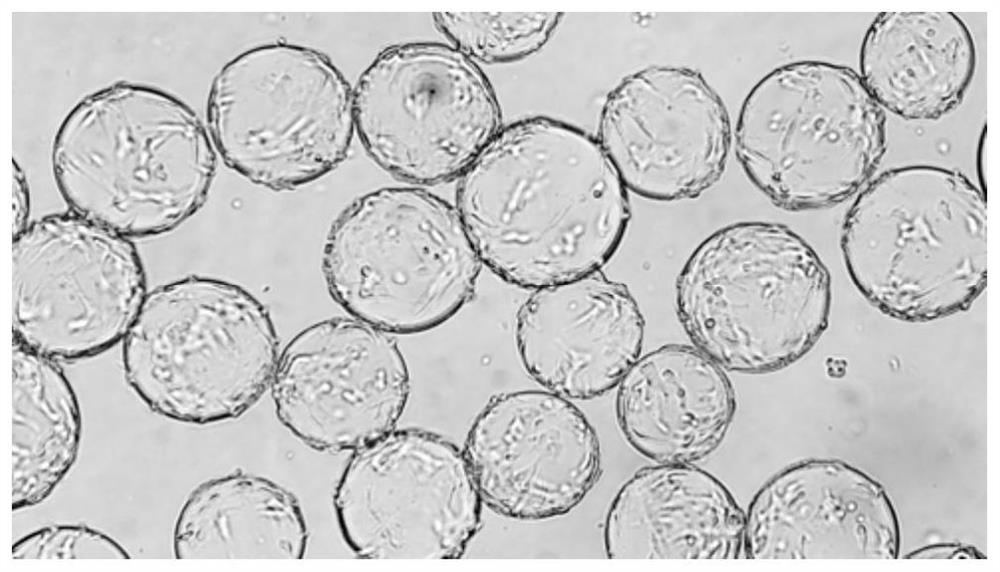

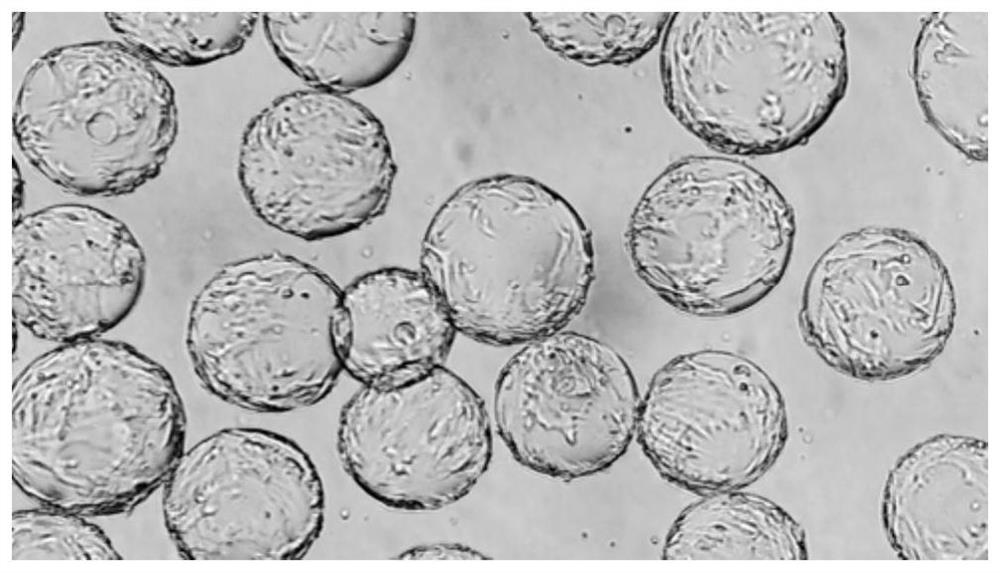

[0031] Embodiment 1 uses BC-7L bioreactor suspension to cultivate grouper cell method

[0032] The method for cultivating grouper cells using BC-7L bioreactor comprises the following steps:

[0033] 1) The grouper GS cells were digested with 0.25% trypsin digestion solution to prepare a cell suspension; the trypsin digestion solution included 0.02% ethylenediaminetetraacetic acid and 0.25% trypsin (1 :250);

[0034] 2) Inoculate the cell suspension prepared in step 1) into a BC-7L bioreactor containing cell growth fluid and microcarriers for dynamic culture; the amount of cell growth fluid added is 1000ml; including 800ml basal medium, 50ml Galactose, 150ml grouper tissue fluid; the basal medium is DMEM basal medium, and the preparation process of the grouper tissue fluid is: add 100ml normal saline to 10g grouper tissue, grind and stir, and centrifuge the supernatant at 10000rpm Liquid, sterilized and filtered, to get it; the microcarrier is Cytodex1; the addition amount is...

Embodiment 2

[0036] Embodiment 2 uses BC-7L bioreactor suspension culture grouper cell method

[0037] The method for cultivating grouper cells using BC-7L bioreactor comprises the following steps:

[0038] 1) The grouper GS cells were digested with 0.25% trypsin digestion solution to prepare a cell suspension; the trypsin digestion solution, in terms of mass fraction, included 0.02% ethylenediaminetetraacetic acid and 0.25% trypsin ( 1:250);

[0039] 2) Inoculate the cell suspension prepared in step 1) into the BC-7L bioreactor containing cell growth liquid and microcarriers for dynamic culture; the addition of cell growth liquid is 900ml, including 738ml basal medium, 72ml Galactose, 90ml grouper tissue fluid; the basal medium is DMEM basal medium, and the preparation process of the grouper tissue fluid is: add 100ml normal saline to 10g grouper tissue, grind and stir, and centrifuge the supernatant at 10000rpm liquid, after sterilizing and filtering, to obtain; the addition amount is ...

Embodiment 3

[0041] Embodiment 3 uses BC-7L bioreactor suspension to culture grouper cell method

[0042] The method for cultivating grouper cells using BC-7L bioreactor comprises the following steps:

[0043] 1) The grouper GS cells were digested with 0.22% trypsin digestion solution to prepare a cell suspension; the trypsin digestion solution, in terms of mass fraction, included 0.01% ethylenediaminetetraacetic acid and 0.22% trypsin ( 1:250);

[0044] 2) Inoculate the cell suspension prepared in step 1) into the BC-7L bioreactor containing cell growth liquid and microcarriers for dynamic culture; the addition of cell growth liquid is 900ml, including 738ml basal medium, 72ml Galactose, 90ml grouper tissue fluid; the basal medium is DMEM basal medium, and the preparation process of the grouper tissue fluid is: add 100ml normal saline to 10g grouper tissue, grind and stir, and centrifuge the supernatant at 10000rpm liquid, after sterilizing and filtering, to obtain; the microcarrier is Cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com