Offshore wind power sacrificial anode protection process

A sacrificial anode protection, offshore wind power technology, applied in the field of protection technology, can solve problems such as threats to the safe operation and long-term use of steel pipe piles, and achieve stable and reliable protection effects, resistance to mechanical damage, and corrosion inhibition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

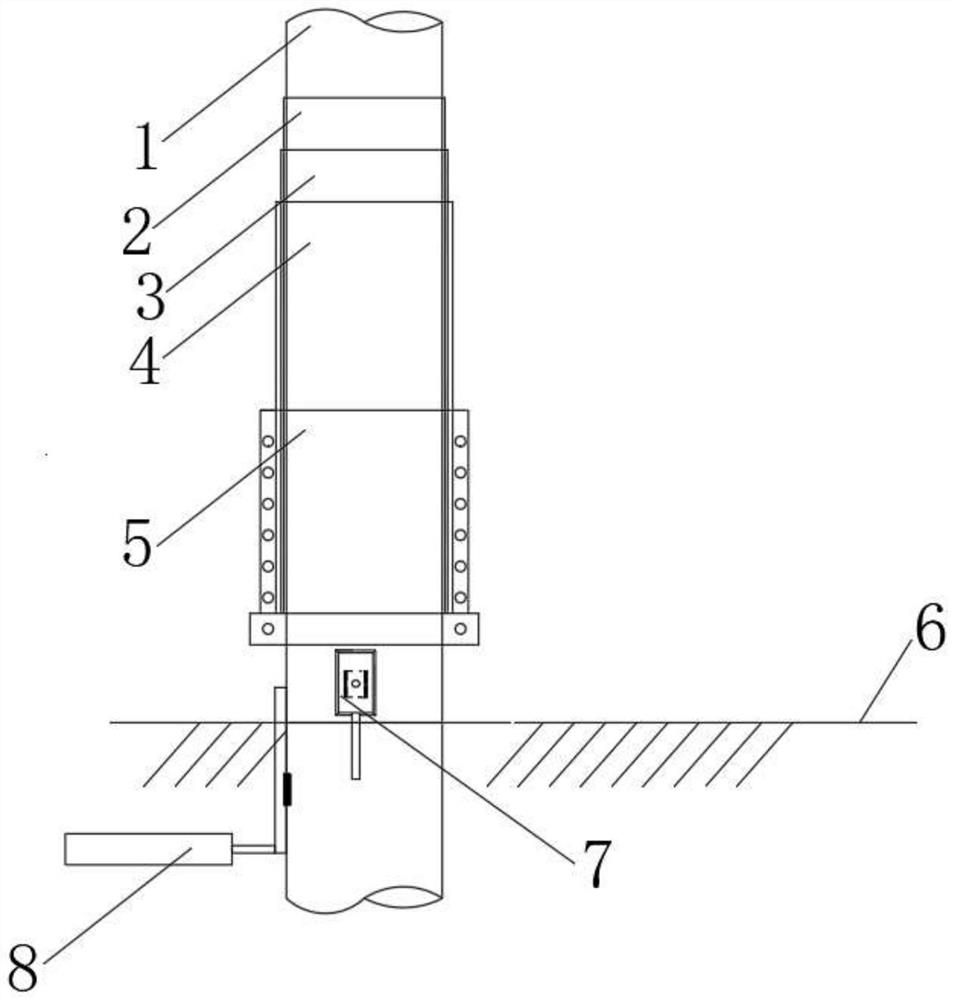

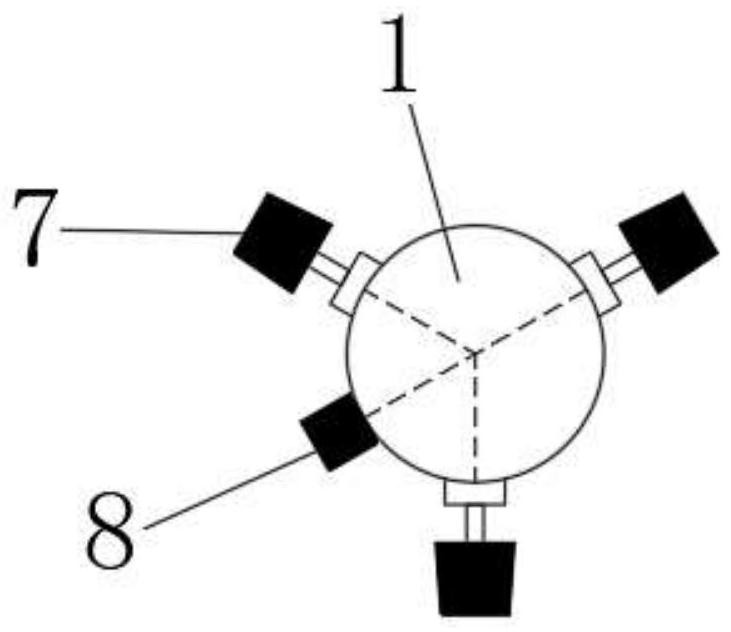

[0050] Offshore wind power sacrificial anode protection process, including the following steps:

[0051] S1. Firstly, steel pipe piles are divided into atmospheric area, tidal range area, full immersion area and submud area according to the actual situation;

[0052] S2. Then calculate the sum of the areas of the atmospheric zone and the tidal zone, and coat the outside of the steel pipe piles within the atmospheric zone and the tidal zone with mineral anti-corrosion paste. The mineral anti-corrosion paste is an artificial light brown oily paste Corrosion inhibitor compound, directly applied on the surface of steel structure, has good anti-corrosion performance in humid environment, can effectively and stably protect steel structure from corrosion in severe corrosive environment for a long time, the compound anti-corrosion compound in mineral anti-corrosion paste The rust conversion agent contained in the rust agent can convert the rust layer on the metal surface into a hard c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com