Developing solution composition used in silicon-based OLED manufacturing process

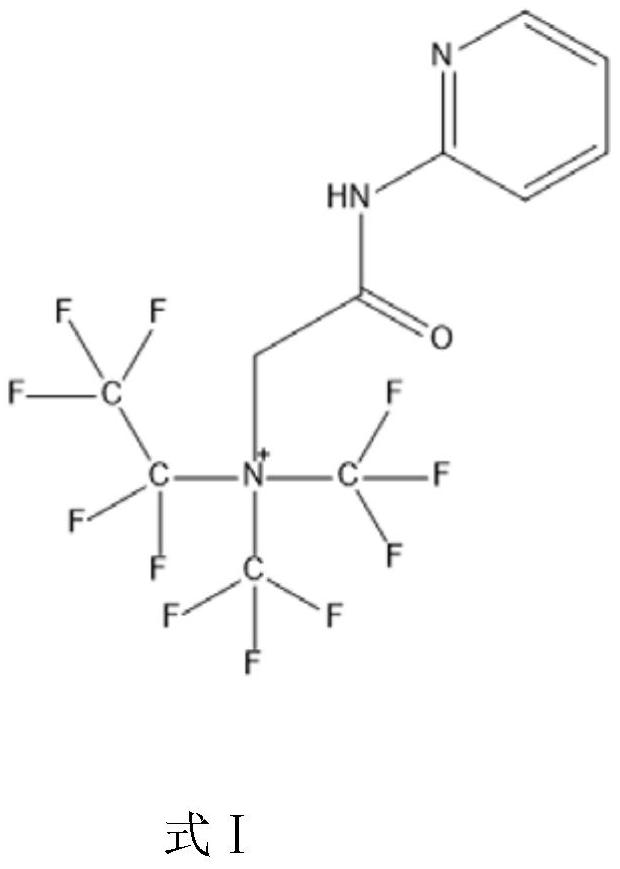

A developer solution and composition technology, applied in the field of silicon-based OLED manufacturing, can solve the problems that the dispersion stability of surfactants cannot reach the high PPI fineness of the product, it is difficult to meet the process requirements of silicon-based OLEDs, and silicon-based materials are not suitable. , to achieve the effect of enhancing the water solubility of salts, excellent uniformity, and improving requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0018] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

[0019] The following examples further illustrate the present invention, but the present invention is not limited to the scope of the described examples.

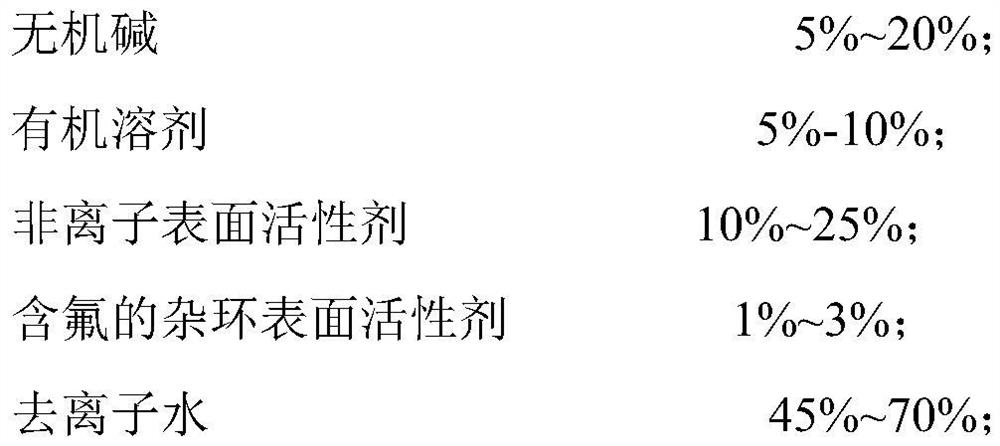

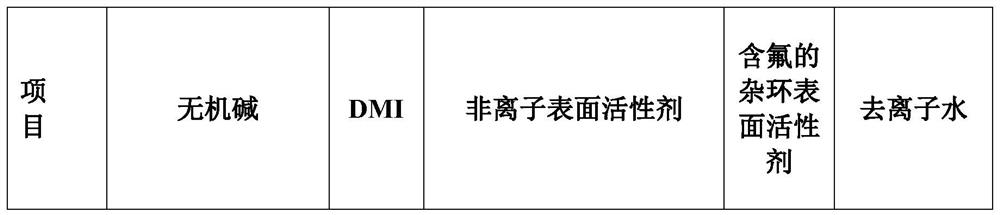

[0020] Examples and comparative examples

[0021] According to the formula in Table 1, the developer solution for silicon-based OLED manufacturing process was prepared. The specific preparation method was to add deionized water to the stirring tank at room temperature, and then add inorganic alkali, organic solvent, non-ionic surfactant and For heterocyclic surfactants containing fluorine, each material is put in and stirred until the system is clear before adding the next material. After all the addition is complete, stir for another 30 minutes, and then filter through filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com